3D printed all-through tubular hydrogel support and preparation method thereof

A 3D printing and hydrogel technology, applied in manufacturing, medical science, liquid material additive processing, etc., can solve the problems of low precision of tubular structures, large selection limitations, slow speed, etc., and achieve flexible size controllability , the preparation process is simple, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

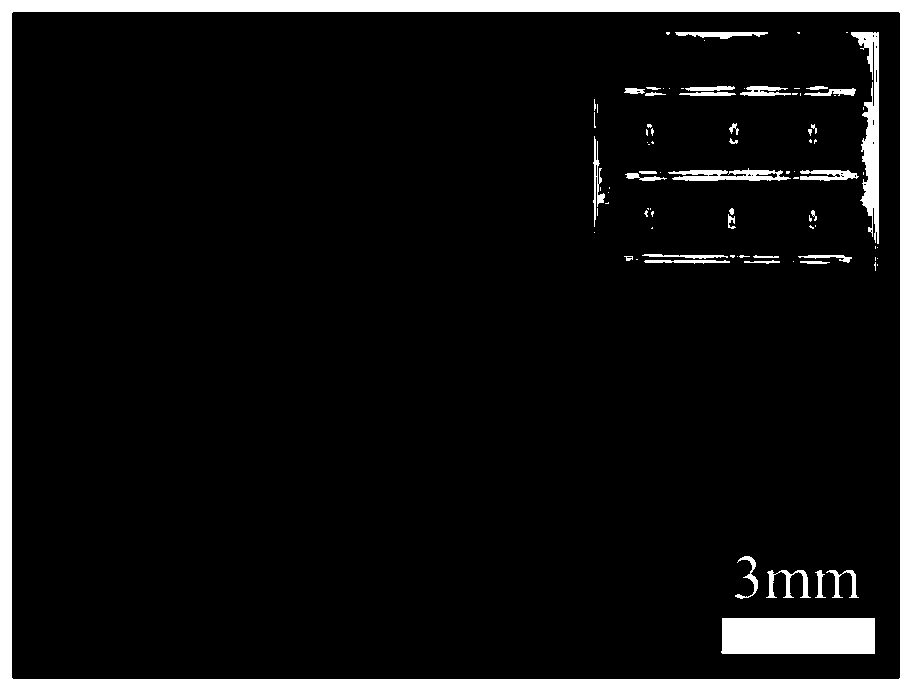

[0032] 4.5 g chitosan and 0.5 g gelatin powder were dispersed in 100 g of 1 vol.% acetic acid aqueous solution, stirred at 20 °C for 8 h to form a transparent solution, and then poured into a 30 cc printing cartridge and sealed. Stand in an oven at 30°C for 48 hours to remove air bubbles in the solution to obtain a chitosan / gelatin composite solution. Set the barrel temperature of the 3D printer to 40 °C, the extrusion pressure to 1.0 bar, and the traction speed to 50 mm / s, print on a platform at 4 °C, and obtain thermally reversible chitosan / gelatin based on gelatin gel curing Composite hydrogel scaffolds. Soak the above-mentioned hydrogel scaffold in 0.1 mol / L sodium thiosulfate aqueous solution for 1 min, take it out and cut off the edge end of the hydrogel scaffold, and then heat-wash it in deionized water at 20 °C for 60 min, and finally get a A three-dimensional hydrogel scaffold with a fully penetrating tubular structure.

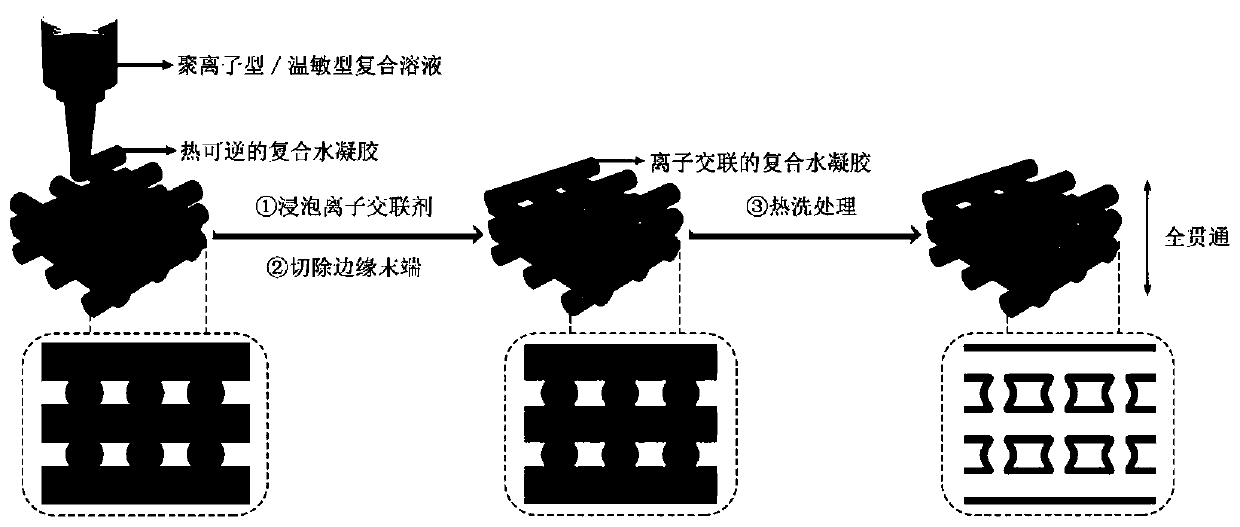

[0033] figure 1 It is a schematic diagram o...

Embodiment 2

[0037] Disperse 9 g of chitosan and 9 g of collagen powder in 100 g of 5.5 vol.% acetic acid aqueous solution, stir at 40 °C for 6 h to form a transparent solution, then pour it into a 30 cc printing cartridge and seal it. Let it stand in an oven at 40 °C for 40 h to remove air bubbles in the solution to obtain a chitosan / collagen composite solution. Set the barrel temperature of the 3D printer to 50 °C, the extrusion pressure to 2.0 bar, and the traction speed to 40 mm / s, print on a platform at 8 °C, and obtain thermally reversible chitosan / collagen based on collagen gel curing Composite hydrogel scaffolds. Soak the above-mentioned hydrogel scaffold in 1.0 mol / L sodium citrate aqueous solution for 30 minutes, take it out and cut off the edge end of the hydrogel scaffold, and then wash it in deionized water at 40 ℃ for 50 minutes, and finally get a three-dimensional A hydrogel scaffold that runs through the tubular structure.

Embodiment 3

[0039] Disperse 4.95 g sodium alginate and 22.55 g collagen in 100 g deionized aqueous solution, stir at 55 °C for 4.5 h to form a transparent solution, then pour it into a 30 cc printing cartridge, seal it, and place it in a 55 °C oven Stand still for 30 h to remove air bubbles in the solution to obtain a sodium alginate / collagen composite solution. Set the barrel temperature of the 3D printer to 70 °C, the extrusion pressure to 3.5 bar, and the traction speed to 30 mm / s, print on a platform at 12 °C, and obtain thermally reversible sodium alginate / collagen based on collagen gel curing. Composite hydrogel scaffolds. Soak the above-mentioned hydrogel scaffold in 2.5 mol / L calcium chloride aqueous solution for 50 minutes, take it out and cut off the edge end of the hydrogel scaffold, and then wash it in deionized water at 55 ℃ for 35 minutes, and finally get a three-dimensional A hydrogel scaffold that runs through the tubular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com