ag/pani/graphene composite photocatalyst and its preparation method and application

A graphene composite and photocatalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve obstacles to applications, metal nanoparticles are easily oxidized and Reunion and other problems, to achieve the effect of reducing production cost, simple preparation method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

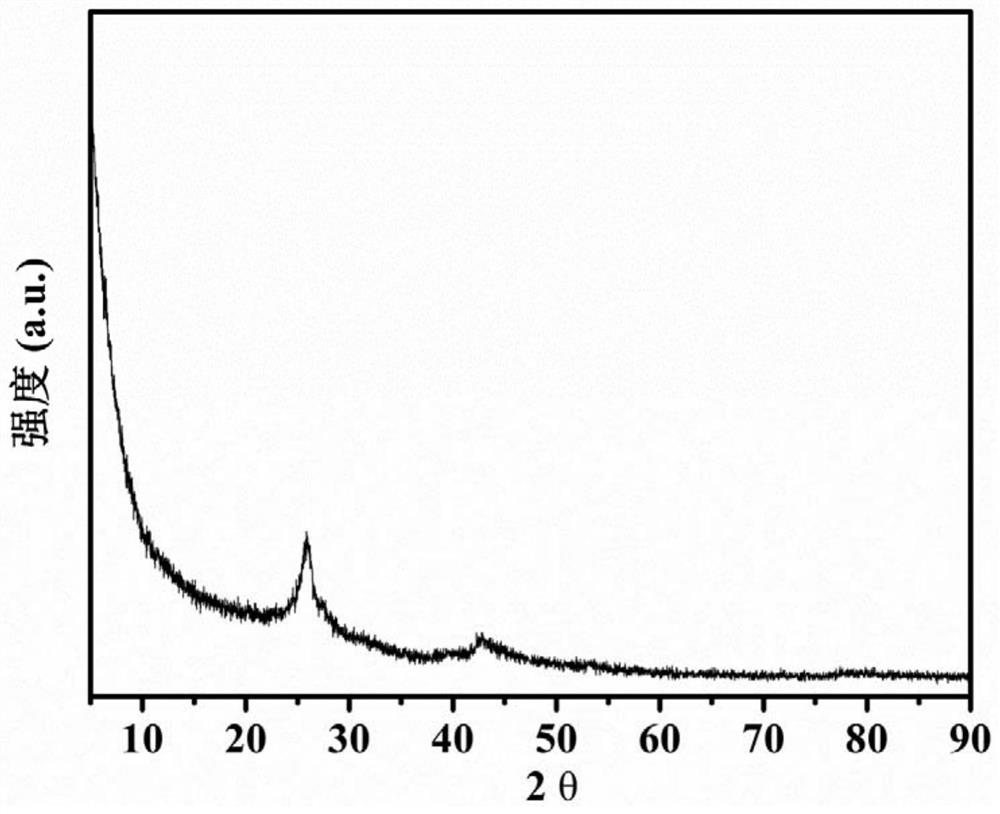

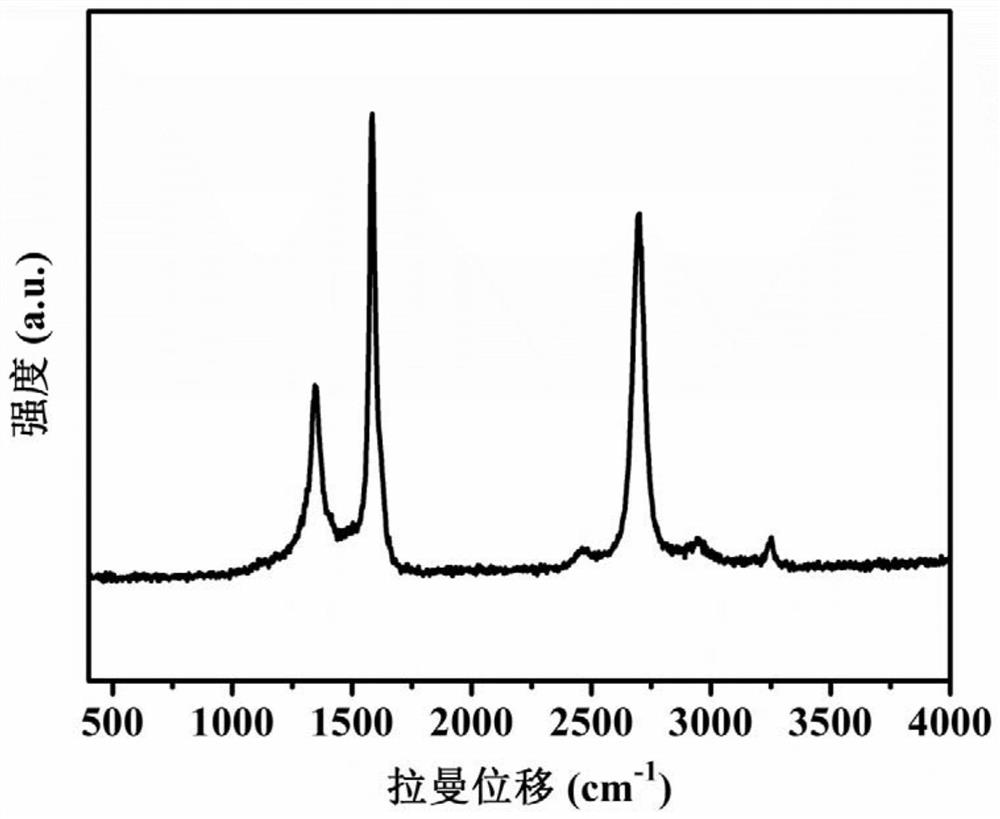

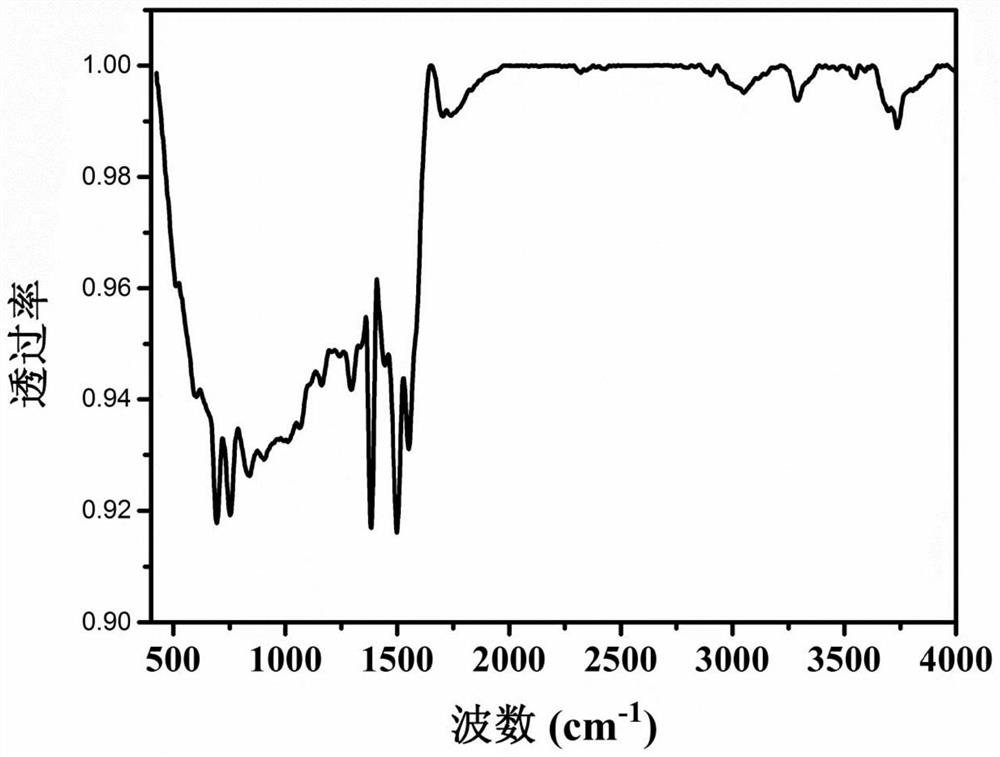

[0031] (1) Preparation of graphene

[0032] First, take the banana peel and dry it in a blast drying oven until it is completely dry, then crush it into banana peel powder, and put it in a tube furnace for pre-carbonization under a nitrogen atmosphere at a rate of 5°C / min from room temperature. The temperature was raised to 500°C by program, and kept at 500°C for 1 hour, and then naturally cooled to room temperature. Weigh 5g of the pre-carbonized powder and mix it with 10g of potassium carbonate (activator) evenly and grind it, then perform the second calcination activation under nitrogen atmosphere, program the temperature from room temperature to 1100°C at a rate of 5°C / min, and Keep warm for 2 hours, then cool down to room temperature naturally. Mix the powder after secondary calcination with 100ml of 0.1mol / L dilute hydrochloric acid, stir for 5 minutes, let stand for 24 hours, wash with deionized water until neutral, and dry at 60°C for 12 hours to obtain biomass few-la...

Embodiment 2

[0042] (1) Preparation of graphene

[0043] With embodiment 1.

[0044] (2) Preparation of Ag / PANI / graphene composite photocatalyst

[0045] Weigh 10mg (1) of the obtained graphene and disperse it in 10ml of deionized water, and ultrasonicate for 10min to obtain dispersion A; mix dispersion A with 0.92g (0.9ml) ANI and 8ml (1mol / L) of AgNO 3 Add to the reaction container and mix, vacuumize and fill the reactor with nitrogen, repeat 3 times, and use a balloon to maintain the nitrogen atmosphere; place it under a full-light light source (300w Xe lamp), irradiate for 10h, and magnetically stir; after the reaction is completed, the liquid is centrifuged, The product in the lower layer was removed, washed with water and alcohol three times each, and dried in vacuum for 6 hours to obtain Ag / PANI / graphene composite photocatalyst 2#Ag / PANI / graphene.

[0046] (3) Determination of photocatalytic activity

[0047] Gained photocatalyst simulates sunlight hydrogen production process an...

Embodiment 3

[0050] (1) Preparation of graphene

[0051] With embodiment 1.

[0052] (2) Preparation of Ag / PANI / graphene composite photocatalyst

[0053] Weigh 10mg of the graphene obtained in (1) and disperse it in 10ml of deionized water, and ultrasonicate for 10min to obtain dispersion D; add dispersion D and 0.92g (0.9ml) ANI into the reaction vessel and mix, vacuumize and fill the reactor with nitrogen , repeated 3 times, using a balloon to maintain its nitrogen atmosphere; placed under a full-light source (300w Xe lamp), irradiated for 10 hours, and magnetically stirred; after the irradiation was completed, 8ml (1mol / L) of AgNO was added 3 , magnetically stirred and reacted for 10 hours; after the reaction was completed, the liquid was centrifuged, and the lower layer product was removed, washed with water and alcohol three times, and dried in vacuum for 6 hours to obtain the Ag / PANI / graphene composite photocatalyst, namely 3#Ag / PANI / graphene.

[0054] (3) Determination of photocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com