Method for preparing nano silver/polystyrene composite material by microemulsion polymerization

A technology of microemulsion polymerization and composite materials, which is applied in the field of microemulsion polymerization to prepare nano-silver/polystyrene composite materials. It can solve the problems that are difficult to effectively solve the uniform dispersion of nano-silver stable PS matrix, and achieve excellent thermal stability. The effect of reunion guarantee and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare 20 mL of sodium citrate and hydrazine hydrate solutions with a concentration of 1 mmol / L and 3 mmol / L, respectively. Under dark conditions, add 25% concentrated ammonia water dropwise to a round bottom flask filled with 20mL silver nitrate solution (10mmol / L) until the precipitate just dissolves to obtain a silver ammonia solution. Under continuous stirring, sodium citrate, polyvinylpyrrolidone and hydrazine hydrate solutions were sequentially added to the silver ammonia solution, and the temperature was 35° C. for 1 hour to prepare sample 1.

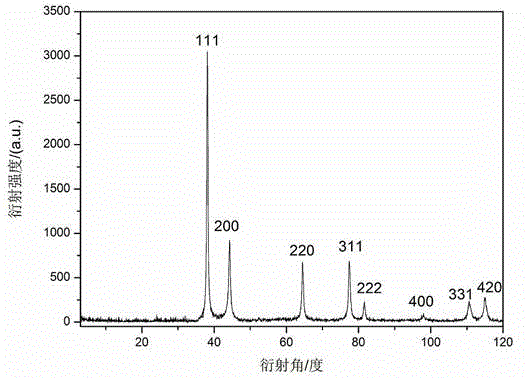

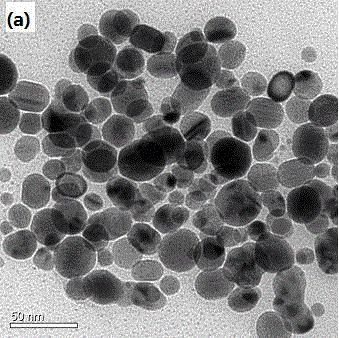

[0036]Use X-ray diffraction and transmission electron microscopy to analyze the phase and microscopic morphology of the product, and its X-ray diffraction pattern is as follows figure 1 shown. According to the X-ray diffraction data, the average size of the sample is calculated by the Scherrer formula to be about 20nm, and the transmission electron microscope photo of sample 1 ( figure 2 ), it can be seen that the aver...

Embodiment 2

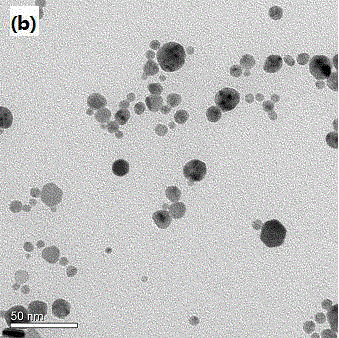

[0038] Prepare sodium citrate solution, silver ammonia solution and polyvinylpyrrolidone solution with concentrations of 1mmol / L, 10mmol / L and 10mmol / L respectively, and mix them in equal volumes. Then add an equal volume of hydrazine hydrate solution with a concentration of 3 mmol / L. The temperature was 35° C. for 1 hour to prepare sample 2. The transmission electron microscope photo of sample 2 is as image 3 As shown, it can be seen from the figure that after adding polyvinylpyrrolidone to the system, the average size of nano-silver is reduced to about 10nm, the monodispersity is significantly improved, and there is no agglomeration phenomenon.

Embodiment 3

[0040] Get 3g dodecyltrimethylammonium bromide, 30mL water, 1mL styrene is made into normal phase microemulsion, then add 5mL silver sol prepared by embodiment 2, 0.02g initiator azobisisobutyronitrile (about 2% of the mass of styrene monomer), the temperature was raised to 75°C and reacted for 2 hours to obtain sample 3.

[0041] Figure 4 is the infrared analysis comparison chart of sample 2 and sample 3. From the infrared spectrum, it can be seen that sample 3 is at 3104.3cm -1 、3081.9cm -1 、3059.8cm -1 、3025.7cm -1 and 3001.6cm -1 The infrared absorption peak that appears is the stretching vibration absorption peak of benzene ring hydrogen, 698.7cm -1 The weak infrared absorption that appears is the deformation vibration absorption peak of benzene ring hydrogen, 756.1cm -1 The obvious vibration absorption peak is the out-of-plane deformation vibration absorption peak of methylene, so it is inferred that there is polystyrene in sample 3. Figure 5 is the transmission el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com