Preparation method of composite structure iron orthophosphate for high capacity and high compacted lithium iron phosphate

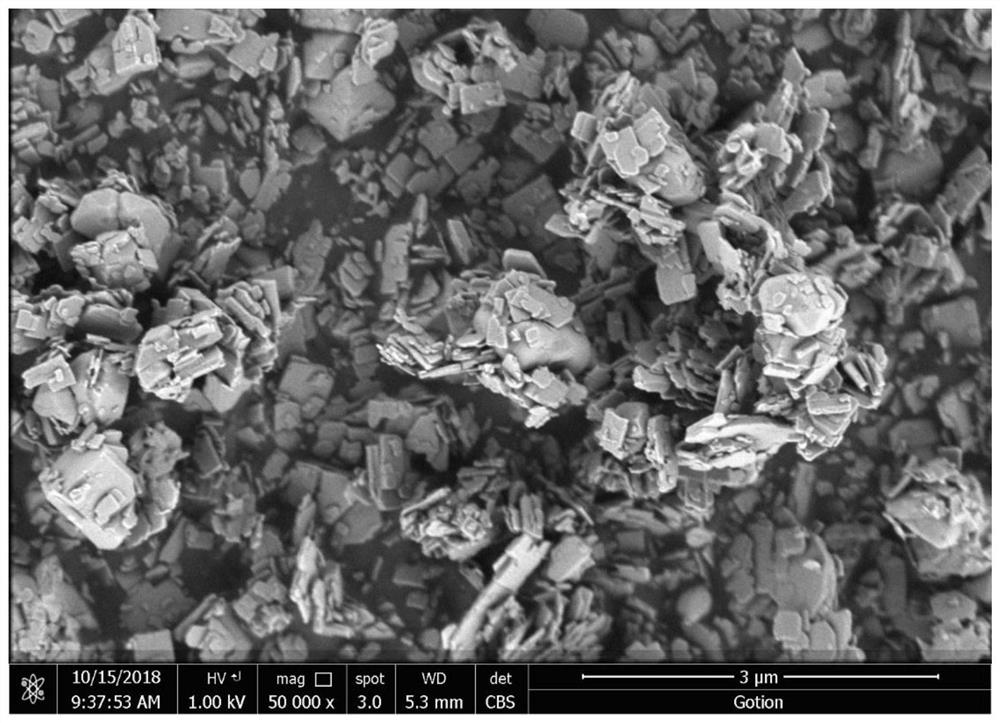

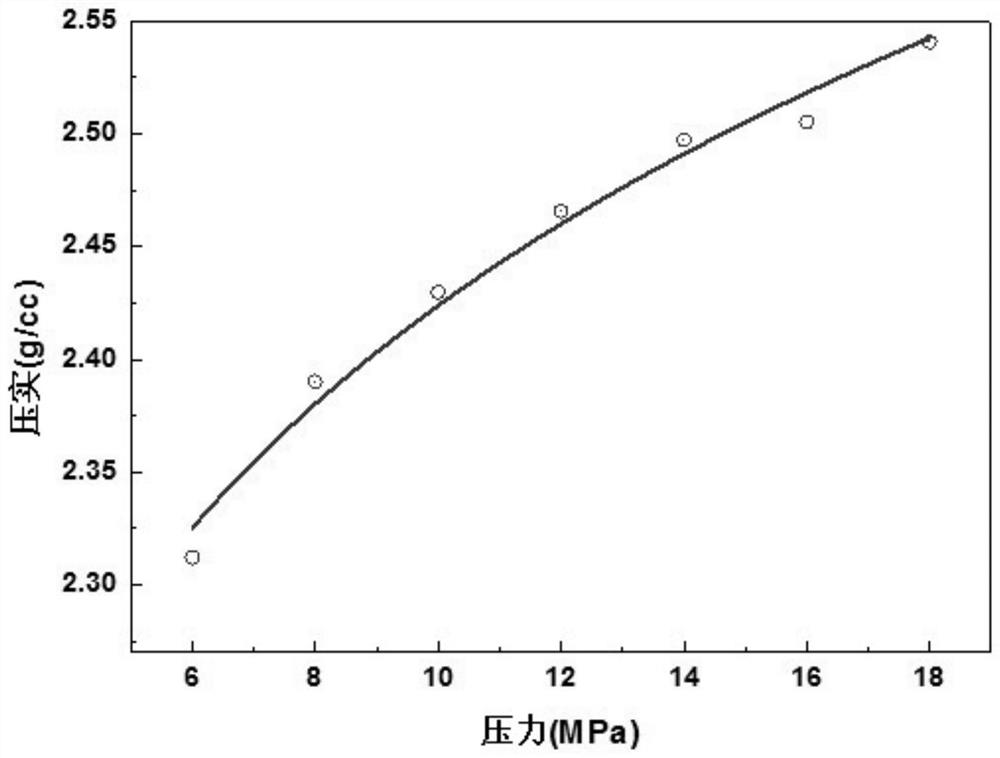

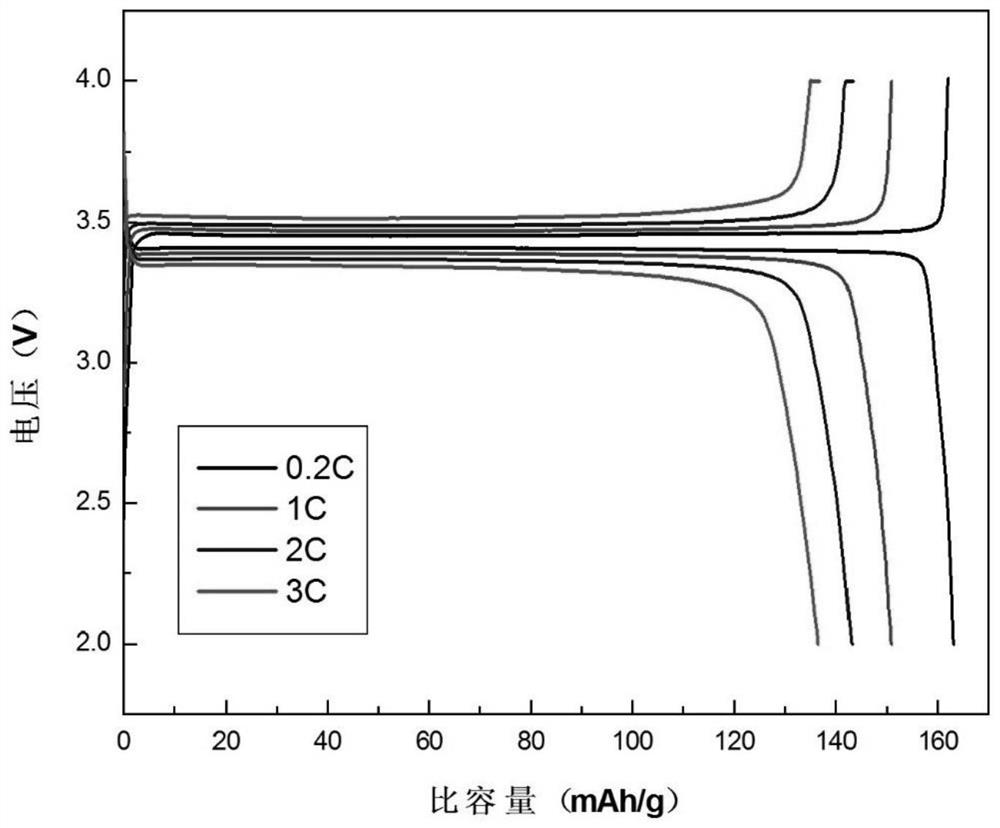

A technology of solid lithium iron phosphate and composite structure, which is applied in the field of preparation of composite structure iron orthophosphate for high-capacity and high-pressure compacted lithium iron phosphate, and can solve the problem of low compaction density, unclear crystal structure and poor processing effect of lithium iron phosphate. To achieve the effect of large-scale industrial production, simple process and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of composite structure iron orthophosphate for high-capacity and high-compression lithium iron phosphate, comprising the following steps:

[0027] S1. Slowly add sulfuric acid into deionized water in the sulfuric acid storage tank and continuously stir and disperse to prepare a sulfuric acid solution with a concentration of 60% for use. In the same manner as the sulfuric acid solution was prepared, phosphoric acid was prepared into a phosphoric acid solution with a concentration of 70% in the phosphoric acid storage tank and continuously stirred and dispersed for use. In the same manner as the sulfuric acid solution was prepared, the hydrogen peroxide solution was prepared into a hydrogen peroxide solution with a concentration of 8% in the hydrogen peroxide storage tank and continuously stirred and dispersed for use.

[0028] S2. Using iron sheets as the iron source, weigh the iron source and add it to the reaction kettle, then add deionized water t...

Embodiment 2

[0037] A preparation method of composite structure ferric orthophosphate for high-capacity and high-compression lithium iron phosphate, comprising the following steps:

[0038] S1. Slowly add sulfuric acid into deionized water in the sulfuric acid storage tank and continuously stir and disperse to prepare a sulfuric acid solution with a concentration of 70% for use. In the same manner as the preparation of the sulfuric acid solution, the phosphoric acid was prepared into a phosphoric acid solution with a concentration of 80% in the phosphoric acid storage tank and continuously stirred and dispersed for use. In the same manner as the sulfuric acid solution was prepared, the hydrogen peroxide solution was prepared into a hydrogen peroxide solution with a concentration of 10% in the hydrogen peroxide storage tank and continuously stirred and dispersed for use.

[0039] S2. Using iron block as the iron source, weigh the iron source and add it to the reactor, then add deionized wat...

Embodiment 3

[0045] A preparation method of composite structure ferric orthophosphate for high-capacity and high-compression lithium iron phosphate, comprising the following steps:

[0046] S1. Slowly add sulfuric acid into deionized water in the sulfuric acid storage tank and continuously stir and disperse to prepare a sulfuric acid solution with a concentration of 65% for use. In the same manner as the sulfuric acid solution was prepared, the phosphoric acid was prepared into a phosphoric acid solution with a concentration of 75% in the phosphoric acid storage tank, and the solution was continuously stirred and dispersed for use. In the same manner as the sulfuric acid solution was prepared, the hydrogen peroxide solution was prepared into a hydrogen peroxide solution with a concentration of 8% in the hydrogen peroxide storage tank and continuously stirred and dispersed for use.

[0047] S2. Use iron scraps as the iron source, weigh the iron source and add it to the reaction kettle, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com