PPy/GO composite electrode material and preparation method and application thereof

A composite electrode and mixed solution technology, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as complex preparation process, difficult electrode forming, poor repeatability, etc., to achieve operability and repeatability Strong, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

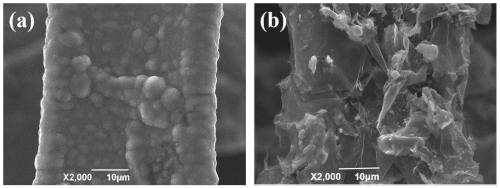

[0035] The pure PPy electrode preparation method of the present embodiment is carried out according to the following steps:

[0036] Step 1: Add 2.8 mL of pyrrole monomer to 200 mL of 0.1 M sodium dodecylbenzene sulfonate solution, stir for 20 minutes to obtain a uniform mixed solution; g dodecylbenzenesulfonic acid, then stir the sodium dodecylbenzenesulfonate solution formed evenly;

[0037] Step 2: Put the nickel foam substrate into the mixed solution formed in step 1 as the anode, and the graphite plate as the cathode, and connect the power supply for electrochemical deposition. The deposition temperature is 25°C, the deposition voltage is 3.0V, and the deposition time is 25 minutes to obtain a pure PPy electrode. .

Embodiment 2

[0039] The preparation method of the PPy / GO composite electrode of the present embodiment is carried out according to the following steps:

[0040] Step 1: Add 1.4 mL of pyrrole monomer to 100 mL of sodium dodecylbenzenesulfonate solution and stir for 20 minutes to obtain a uniform mixed solution; Dialkylbenzenesulfonic acid, then stir the sodium dodecylbenzenesulfonate solution that forms evenly;

[0041]Step 2: Add 100 mL of graphene oxide dispersion with a concentration of 1 g / L to the mixed solution formed in step 1, ultrasonicate the mixed solution for 10 minutes, and magnetically stir for 20 minutes to obtain a uniform mixed solution; Prepared by the Hummers method, add 3g NaNO in a 500mL round bottom flask 3 , 3 g of graphite and 100 mL of concentrated H 2 SO 4 , and kept stirring for 30 min in an ice-water bath. 9g KMnO 4 Slowly add it into the flask under vigorous stirring, then remove the ice bath, keep stirring the mixed solution at 35°C for 1 hour, then add 10...

Embodiment 3

[0044] The preparation method of the PPy / GO composite electrode of the present embodiment is carried out according to the following steps:

[0045] Step 1: Add 1.4 mL of pyrrole monomer to 100 mL of sodium dodecylbenzenesulfonate solution and stir for 20 minutes to obtain a uniform mixed solution; Dialkylbenzenesulfonic acid, then stir the sodium dodecylbenzenesulfonate solution that forms evenly;

[0046] Step 2: Add 100 mL of graphene oxide dispersion with a concentration of 1 g / L to the mixed solution formed in step 1, ultrasonicate the mixed solution for 10 minutes, and magnetically stir for 20 minutes to obtain a uniform mixed solution; Prepared by the Hummers method, add 3g NaNO in a 500mL round bottom flask 3 , 3 g of graphite and 100 mL of concentrated H 2 SO 4 , and kept stirring for 30 min in an ice-water bath. 9g KMnO 4 Slowly add it into the flask under vigorous stirring, then remove the ice bath, keep stirring the mixed solution at 35°C for 1 hour, then add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com