Lignin-based carbon dots with high fluorescence quantum yield and preparation method of lignin-based carbon dots

A fluorescence quantum yield, lignin-based technology, which is applied in the field of lignin-based carbon dots with high fluorescence quantum yield and its preparation, can solve the problems of low fluorescence quantum yield, harsh operating conditions, and complicated steps, and achieve fluorescence The effect of high quantum yield, low equipment requirements and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

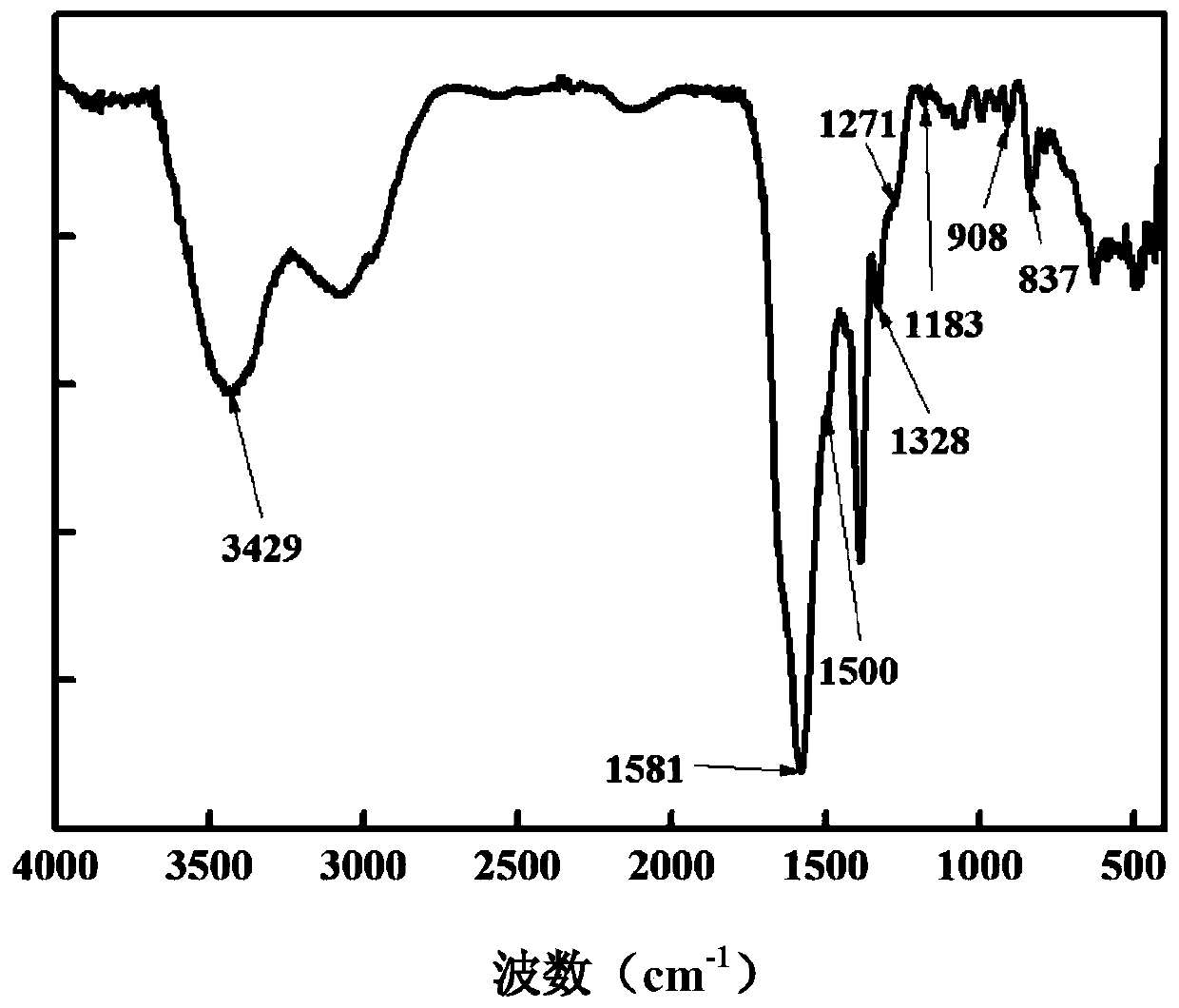

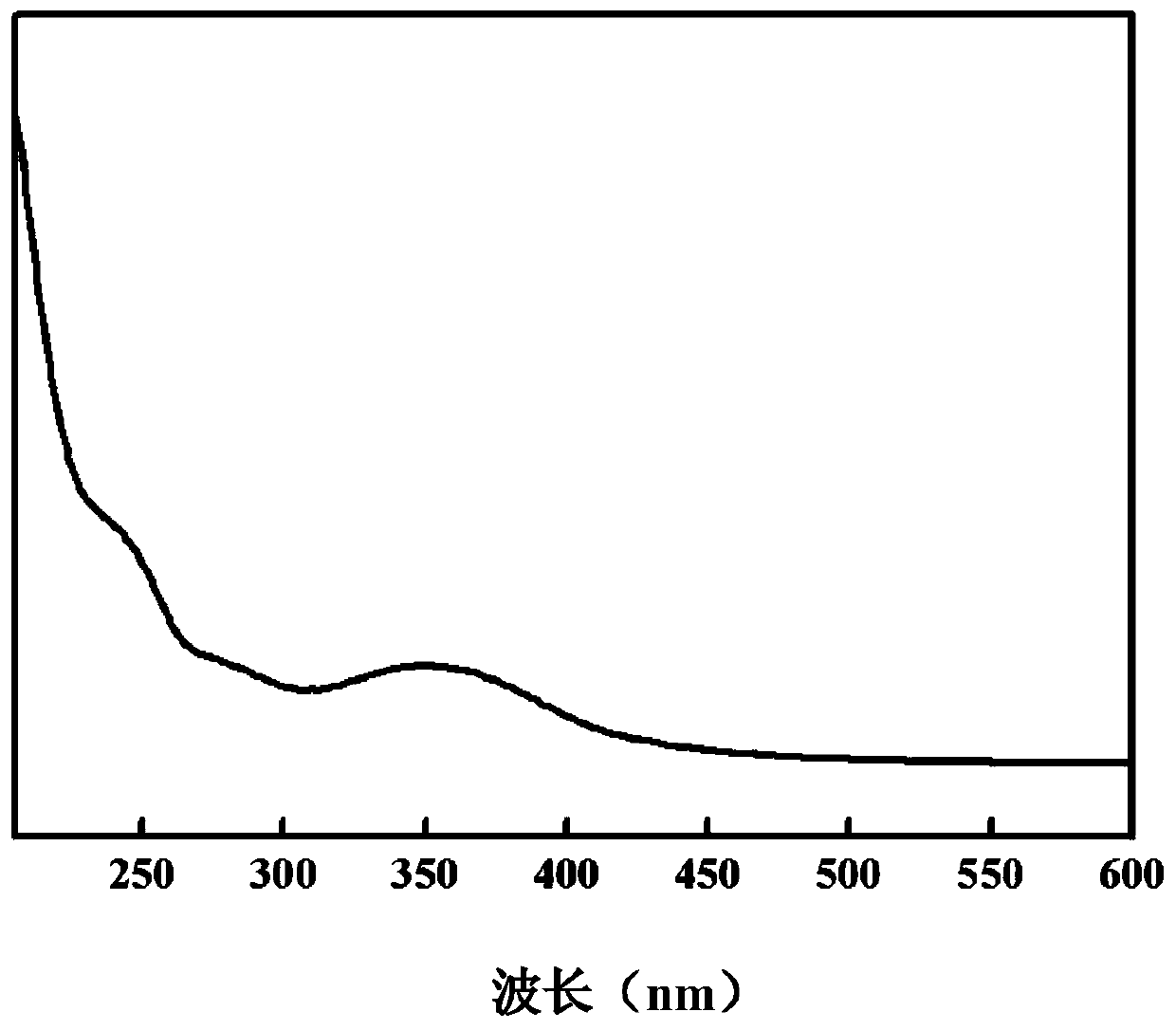

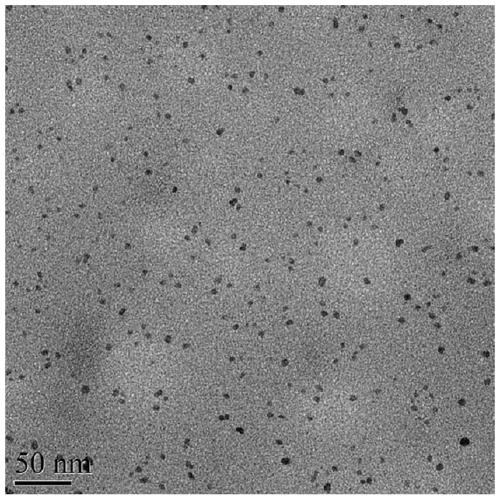

Embodiment 1

[0038] Add 2.40 parts by mass of ethylenediamine to 60 parts by mass of water to form an ethylenediamine solution. Add 0.075 parts by mass of lignin solid powder and 2.10 parts by mass of citric acid monohydrate to the ethylenediamine solution prepared by the above method, and disperse the mixed solution by ultrasonic oscillation for 10 minutes before transferring it to a high-pressure reactor. Raise the temperature to 180°C at a rate of 5°C / min. Under the condition of 180°C, heat it with constant temperature water for 9 hours, take it out, and let it cool down to room temperature naturally. After cooling to room temperature, the reaction product was taken out and centrifuged at 8000 rpm for 10 min. The supernatant liquid was collected, passed through a 0.22 μm filter membrane and dialyzed to remove incompletely reacted substances, and thus obtained carbon dots using lignin as a raw material, and its fluorescence quantum yield was measured to be 43.9%.

Embodiment 2

[0040] Add 1.00 parts by mass of 50% polyethyleneimine (PEI) and 2.40 parts by mass of ethylenediamine to 60 parts by mass of water to form a mixed solution of PEI and ethylenediamine. Add 0.1 parts by mass of solid lignin powder and 2.10 parts by mass of citric acid monohydrate to the mixed solution of PEI and ethylenediamine prepared by the above method, and disperse the mixed solution by ultrasonic oscillation for 8 minutes before transferring it to a high-pressure reactor. Raise the temperature to 200°C at a rate of 5°C / min. Under the condition of 200°C, heat it with constant temperature water for 12 hours, take it out, and let it cool down to room temperature naturally. After cooling to room temperature, the reaction product was taken out and centrifuged at 10000 rpm for 15 min. The supernatant liquid was collected, passed through a 0.22 μm filter membrane and dialyzed to remove incompletely reacted substances, and thus obtained carbon dots using lignin as a raw material,...

Embodiment 3

[0042]Add 0.50 parts by mass of urea to 60 parts by mass of water to form a urea solution. Add 0.10 parts by mass of lignin solid powder and 2.10 parts by mass of citric acid monohydrate to the urea solution prepared by the above method, disperse the mixed solution by ultrasonic oscillation for 18 minutes, and then transfer it to a high-pressure reactor. Raise it to 200°C at a rate of 4°C / min. Under the condition of 200°C, heat it with constant temperature water for 12 hours, take it out, and let it cool down to room temperature naturally. After cooling to room temperature, the reaction product was taken out and centrifuged at 13000 rpm for 18 min. The supernatant liquid was collected, passed through a 0.22 μm filter membrane and dialyzed to remove incompletely reacted substances, and obtained carbon dots using lignin as raw material, and the measured fluorescence quantum yield was 19.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com