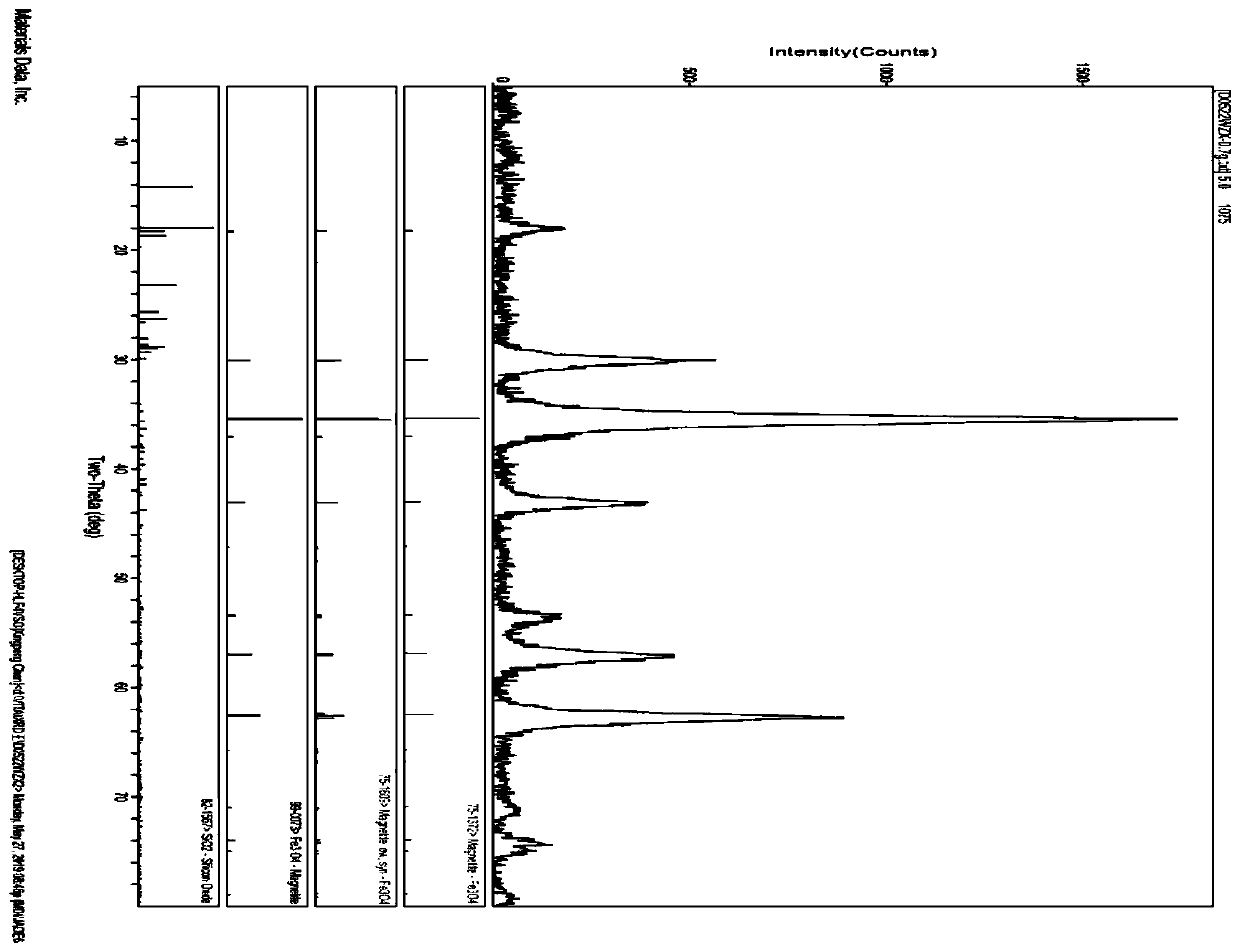

Preparation method of double-layer Fe3O4@SiO2 magnetic composite nanoparticle

A magnetic composite nanometer and ferroferric oxide technology, which is applied in the direction of iron oxide/hydroxide, silicon dioxide, silicon oxide, etc., can solve the problems of difficult disposal of waste liquid, high processing cost, and easy pollution of the environment. The effect of dense silicon oxide structure, uniform particle size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the double-layer ferroferric oxide@silicon dioxide magnetic composite nano-particles of the present invention obtains double-layer ferric oxide@silicon dioxide magnetic composite nanoparticles with a dense structure and good monodispersity through a large number of experimental investigations , including the following steps:

[0029] Step 1: Disperse iron ferric oxide nanoparticles in trisodium citrate, heat treatment in a water bath at 80°C for 1 hour, then alternately wash with acetone and deionized water, and dry in vacuum at 30°C for 24 hours to obtain treated ferric iron tetroxide particles .

[0030] Wherein, the particle diameter of ferric oxide nanoparticles is 20nm. The concentration of the trisodium citrate is 0.1mol / L, the volume is 200ml, and the ratio of acetone and deionized water is 1:3. The volume fraction of acetone is 99.5%.

[0031] Step 2: Weigh the iron ferric oxide particles obtained in step 1, ultrasonically disperse t...

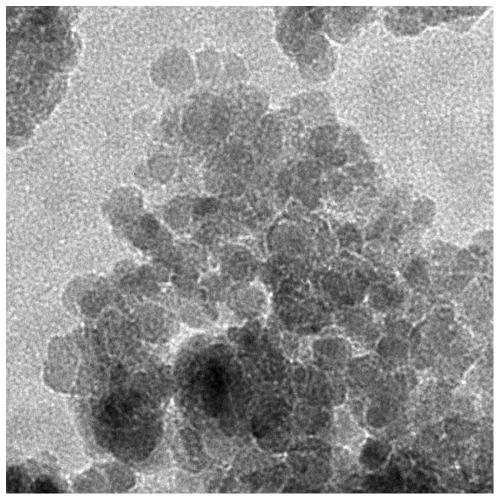

Embodiment 1

[0036] Step 1: Disperse 0.5g of 20nm spherical ferric ferric oxide in 200ml of 0.1mol / l trisodium citrate, bathe in water at 80°C for 1 hour, wash alternately with acetone and deionized water, the ratio of acetone to deionized water is 1:3, and dried in a vacuum oven at 30°C for 24 hours to obtain the treated ferric oxide particles.

[0037] Step 2: Weigh 0.5 g of ferric oxide particles treated in Step 1, disperse them in 200 ml of ethanol, and ultrasonicate for 15 min. Then add 100ml of water and 0.2ml of ammonia water, under the stirring condition of 1200r / min at 20°C, add 25ml of ethanol solution dissolved in 0.3ml of tetraethyl orthosilicate to the above solution at a speed of 1ml / min, and react for 4h to obtain a single layer The SiO2-coated Fe3O4@SiO2 composite was washed alternately with deionized water and ethanol several times, and the ratio of deionized water to ethanol was 2:1.

[0038] Step 3: Ultrasonic disperse the Fe3O4@Silicon Dioxide composite material treate...

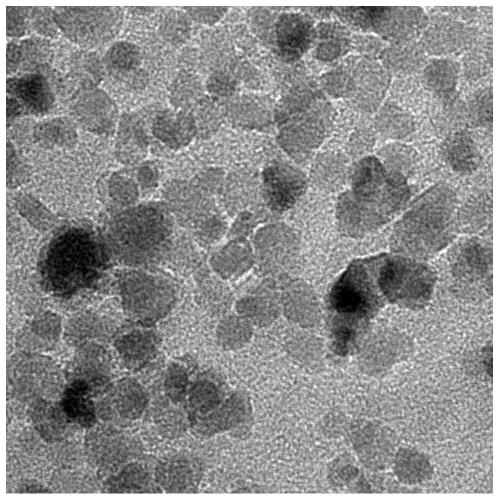

Embodiment 2

[0040] Step 1: Disperse 0.5g of 20nm spherical ferric ferric oxide in 200ml of 0.1mol / l trisodium citrate, bathe in water at 80°C for 1h, wash alternately with acetone and deionized water, the ratio of acetone to water is 1: 3. Drying in a vacuum oven at 30° C. for 24 hours to obtain treated ferric oxide particles.

[0041]Step 2: Weigh 0.5 g of ferric oxide particles treated in Step 1, disperse them in 200 ml of ethanol, and ultrasonicate for 15 min. Then add 100ml of water and 0.3ml of ammonia water, under the stirring condition of 1200r / min at 60°C, add 25ml of ethanol solution dissolved in 0.5ml of tetraethyl orthosilicate to the above solution at a speed of 1ml / min, and react for 4h to obtain a single layer The SiO2-coated Fe3O4@SiO2 composite was washed alternately with deionized water and ethanol several times, with the ratio of deionized water to ethanol being 2:1, until the solution was neutral and clear.

[0042] Step 3: Ultrasonic disperse the Fe3O4@Silicon Dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com