Composite intermediate layer capable of prolonging service life of titanium-based lead dioxide anode and preparation and application thereof

A composite intermediate layer and lead dioxide technology, applied in chemical instruments and methods, electrodes, coatings, etc., can solve the problems of low energy consumption, high energy consumption, and poor durability, and achieve cost reduction, high electrocatalytic activity, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Firstly, a single layer of α-PbO was prepared in one step by using the polished, alkali-washed, and pickled titanium plate as the substrate. 2 -(Nano WC) composite interlayer, and then α-PbO 2 -(Nano WC) The electrode material is the anode, the stainless steel with the same area is the cathode, and the anode is electrooxidized to prepare β-PbO 2 active layer, thus obtaining Ti / α-PbO 2 -(Nano WC) / PbO 2 shape stable anode. α-PbO 2 -(Nano WC) composite intermediate layer preparation process parameters: deposition solution is PbO: 25g / L, NaOH: 150 / L, WC: 10g / L, the concentration of surfactant SBS is 30mg / L, the deposition thickness is controlled to 40μm, direct current Deposition anode current density: 1A / dm 2 , the time is 1h, the stirring rate is 800r / min, the electrodeposition temperature is 50°C, and the electrodeposition time is 1h. After the completion, take out the sample and rinse it with 20% nitric acid, and dry it to get α-PbO with a uniform surface. 2 -(Nan...

Embodiment 2

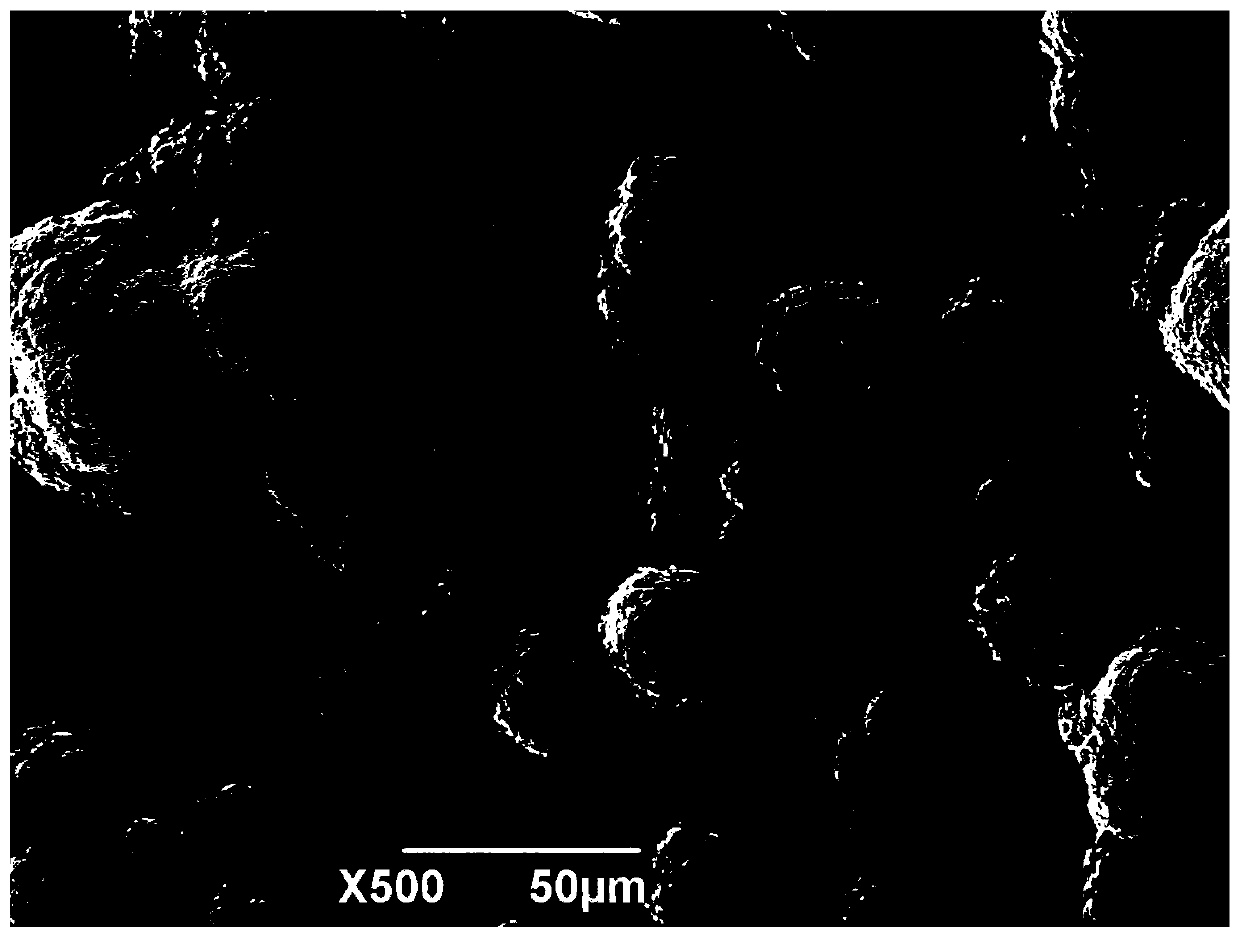

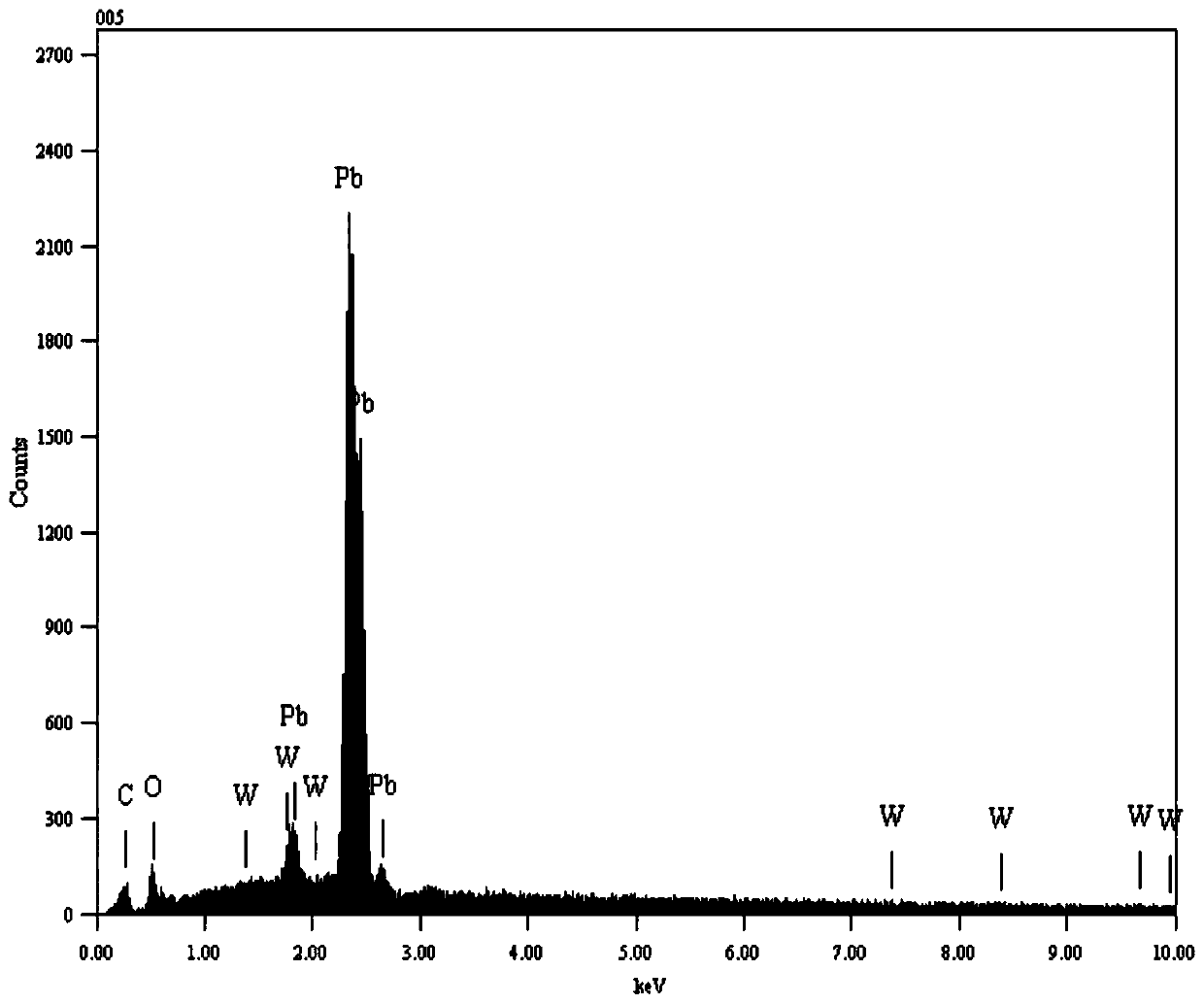

[0026] A single-layer α-PbO was prepared in one step using a polished, alkali-washed, and pickled titanium plate as a substrate by a composite electrodeposition technique. 2 -(Nano WC) composite interlayer, and then α-PbO 2 -(Nano WC) is the anode, the stainless steel of the same size is the cathode, and the anode electrooxidizes to prepare β-PbO 2 active layer, thus obtaining Ti / α-PbO 2 -(Nano WC) / PbO 2 shape stable anode. Carry out SEM, EDX characterization ( figure 1 , 2 ). Indicating that WC recombines into α-PbO 2 In the middle layer, it can be seen from the scanning electron microscope that after compounding into WC particles, the obtained α-PbO 2 -(Nano WC) Composite middle layer is denser.

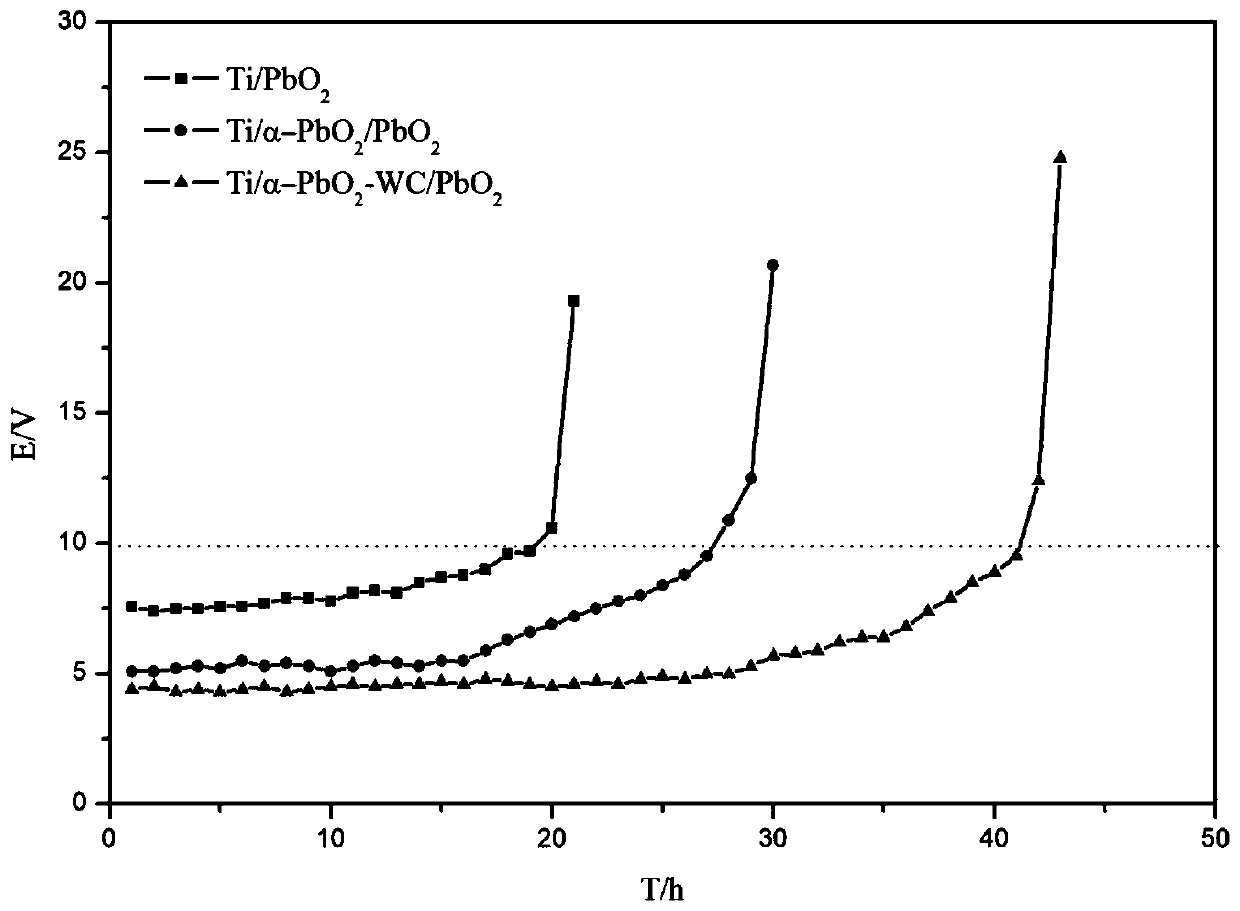

[0027] In summary, the present invention discloses a single-layer corrosion-resistant and conductive α-PbO by one-step method of anode electrochemical co-deposition 2 A method for prolonging the life of a titanium-based lead dioxide anode with a composite interlayer. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com