Electrolyte composition containing metals and silicon in plasma electrolytic oxidation process and method for manufacturing dental implants coated with hydroxyapatite and containing metal ions and silicon ions by using same composition

A plasma electrolysis, metal ion technology, applied in dental preparations, dental implants, dentistry, etc., can solve problems such as insufficient biocompatibility, shortened bone tissue treatment time, etc. The effect of shortening the deadline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

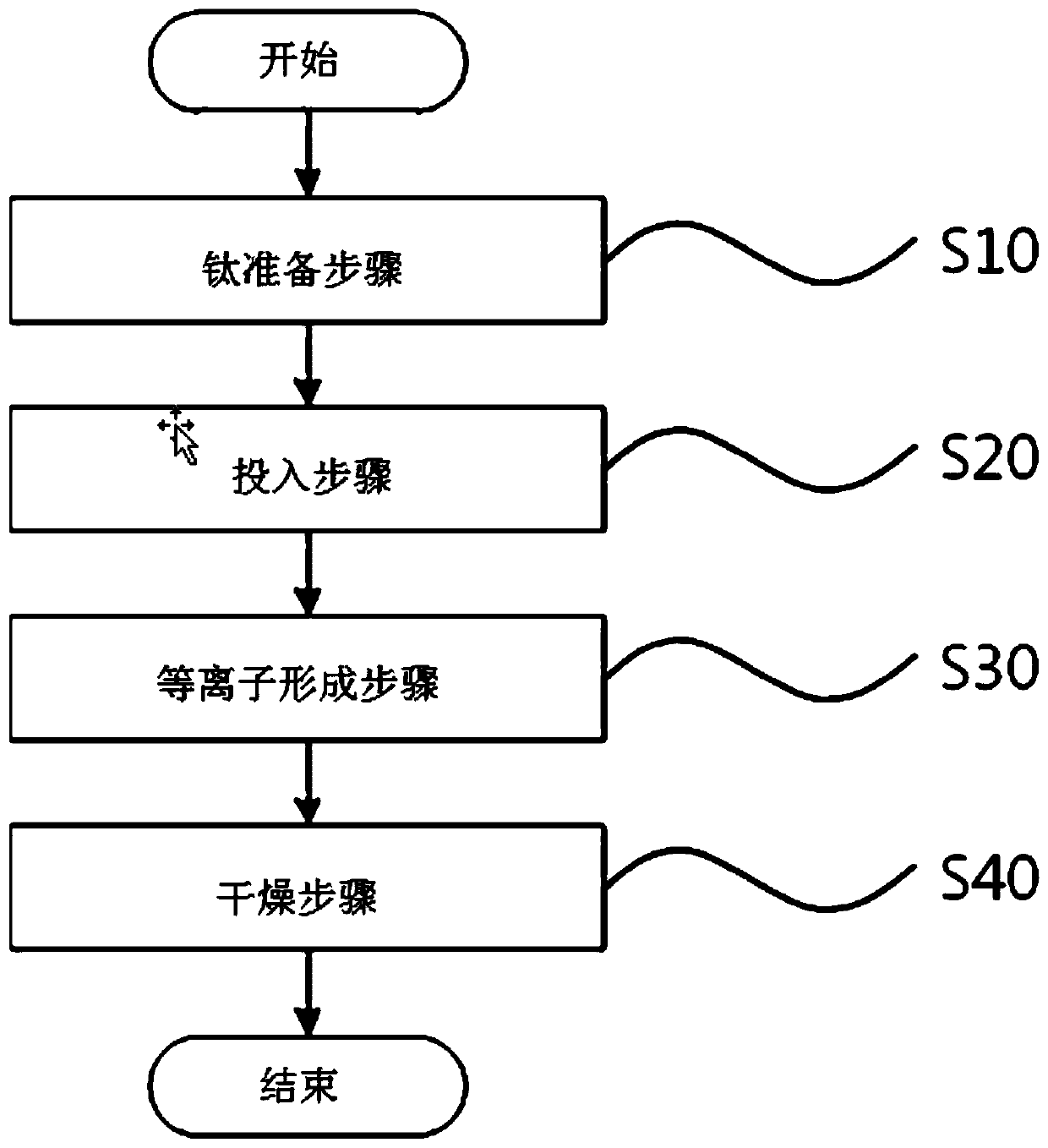

Method used

Image

Examples

Embodiment

[0074] Example: Production of dental implants coated with hydroxyapatite containing metal ions and silicon ions according to the plasma electrolytic oxidation process

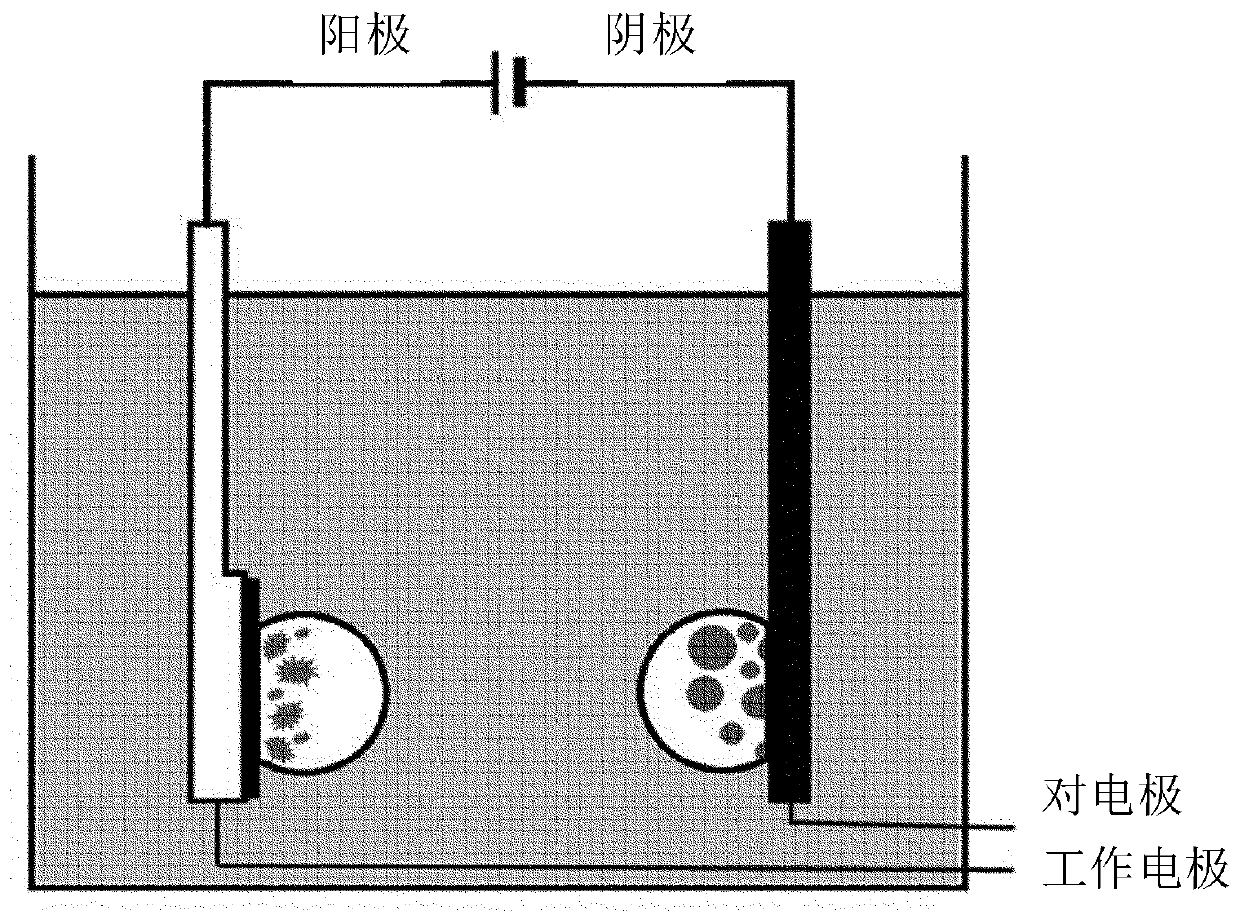

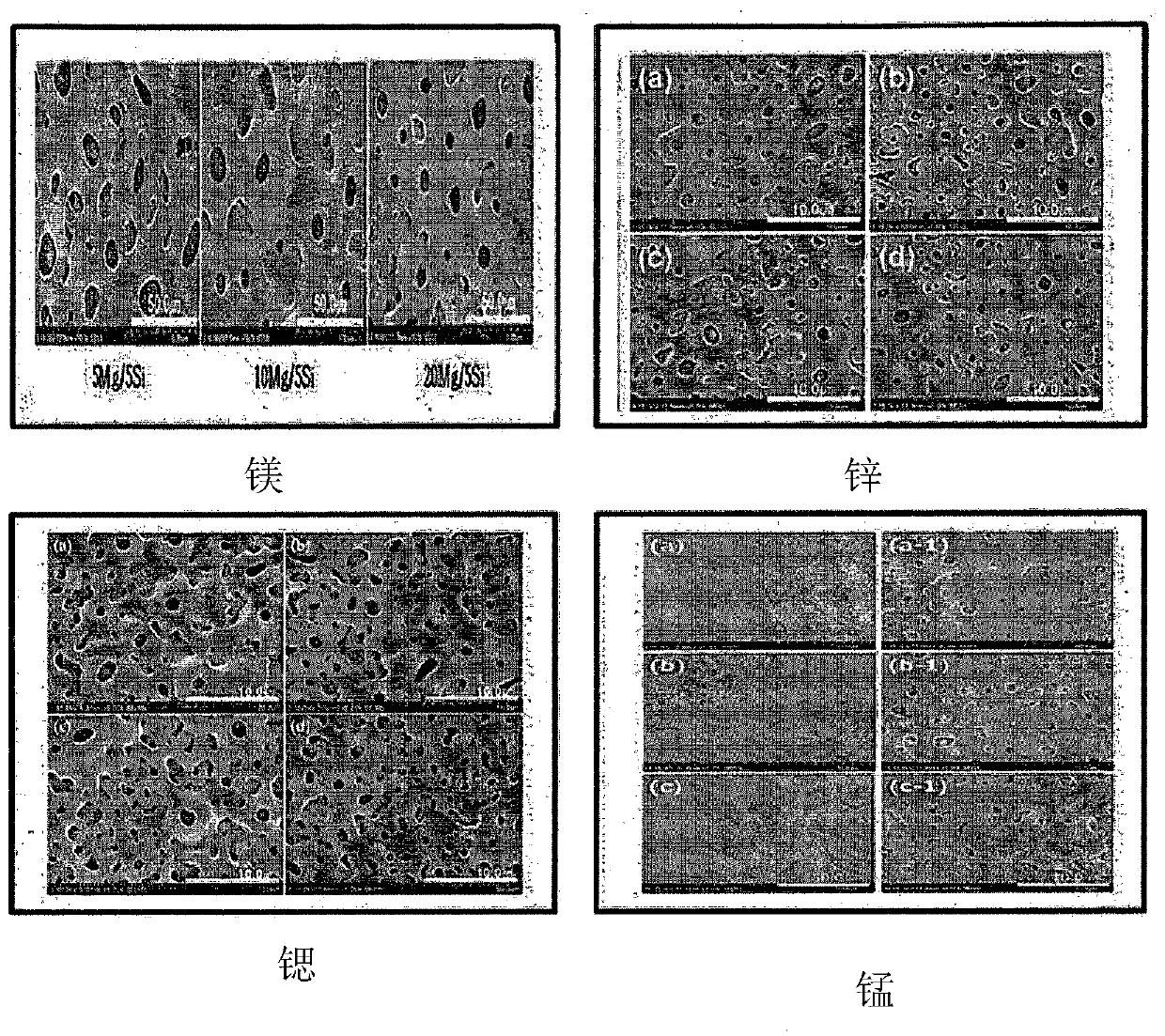

[0075] Utilize silicon carbide sandpaper to grind Ti-6Al-4V disc (grade 5, Timet Co.Ltd, Japan (diameter) (diameter); 10mm, thickness (thickness); 3mm) sample, specifically utilize by 100, 600, Sandpaper composed of 800, 1200, and 2000grit is ground in stages, using aluminum oxide (Al 2 o 3 ) after microgrinding and ultrasonic cleaning, each magnesium ion, zinc ion, strontium ion and manganese ion in the electrolytic solution (each 1 L of distilled water) accounted for 5, 10, 20 mol% relative to calcium ion, and silicon ion relative to Phosphorus ions account for 5 mol%. Like the designs described in the following Table 1 (magnesium), Table 2 (zinc), Table 3 (strontium) and Table 4 (manganese), weigh calcium acetate monohydrate (Calcium acetatemonohydrate), glycerophosphoric acid Calcium glycerophosphate, Mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com