A deep dehydration agent for solid phase sludge

A medicament and sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems such as the inability to meet the technical needs of sludge dewatering, upgrading, upgrading and transformation, and achieve a reduction in land occupation. Small, achieve continuity, and improve the processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

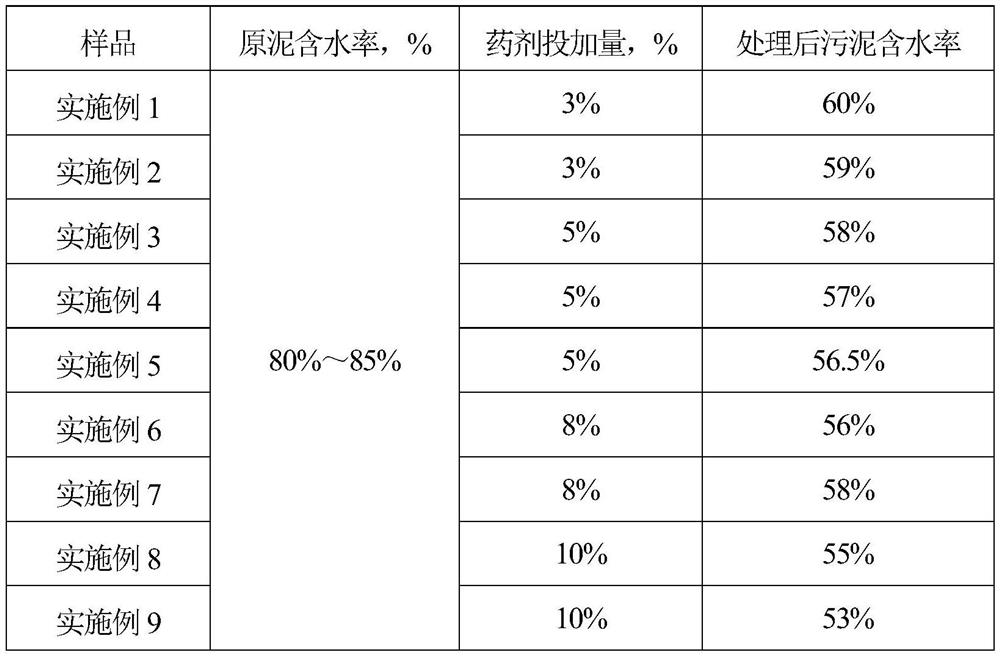

Examples

Embodiment 1

[0024] The dehydrating agent of the present embodiment is made up of following material:

[0025] Inorganic flocculant: 5g polyaluminum chloride;

[0026] Seepage drag reducer: 0.1g polyethylene oxide;

[0027] Cured proppant: 94.8g fly ash;

[0028] Wall breaking agent: 0.1g potassium permanganate.

Embodiment 2

[0030] The dehydrating agent of the present embodiment is made up of following material:

[0031] Inorganic flocculant: 20g polyaluminum chloride;

[0032] Seepage drag reducer: 1.0g polyethylene oxide;

[0033] Cured proppant: 76.0g fly ash;

[0034] Wall breaking agent: 3.0g potassium permanganate.

Embodiment 3

[0036] The dehydrating agent of the present embodiment is made up of following material:

[0037] Inorganic flocculant: 10g polyaluminum chloride;

[0038] Seepage drag reducer: 0.5g polyethylene oxide;

[0039] Cured proppant: 89.0g fly ash;

[0040] Wall breaking agent: 0.5g potassium permanganate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com