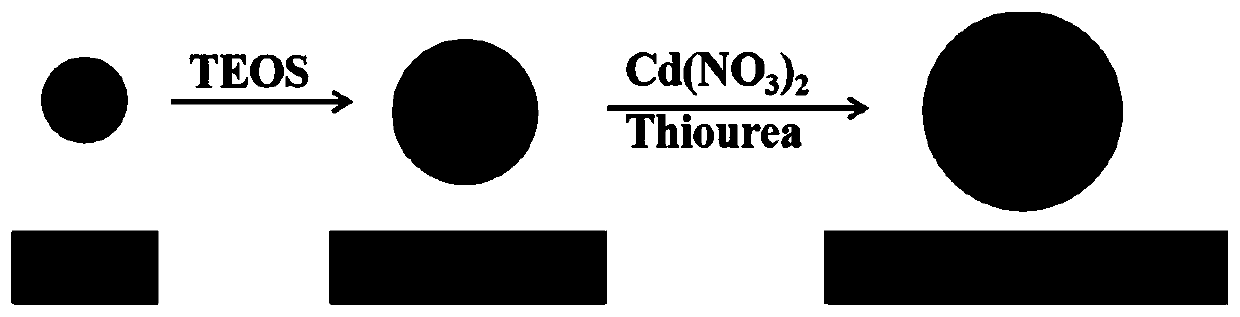

Preparation method and application of superparamagnetic ferroferric oxide@silicon dioxide@cadmium sulfide core-shell nano-structure material

A technology of ferroferric oxide and nano-core shell, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve high energy consumption, complicated preparation process, Long production cycle and other issues, to achieve the effect of precise reaction conditions, simple operation, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

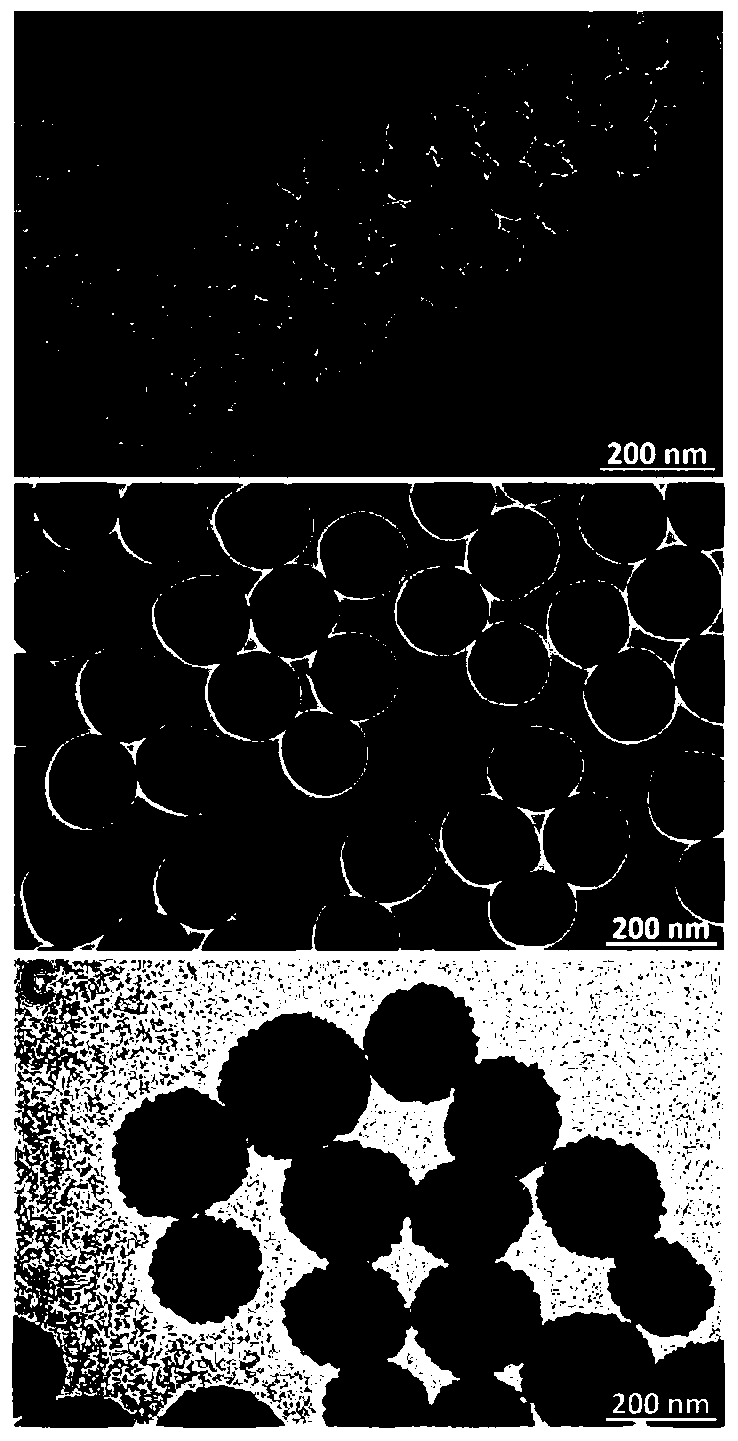

[0032] The first step is to synthesize superparamagnetic ferriferric oxide nanoclusters: sequentially add 0.248g sodium polyacrylate (PAA) and 0.045g ferric chloride to 13mL diethylene glycol (DEG), stir and heat to 205 °C and maintained for one hour. followed by a rapid injection of 1.5mL of 0.15mol L -1 The NaOH DEG solution was stirred at 205°C for 0.5 hours. After the reaction was completed, the reaction liquid was collected by centrifugation, then added 5 mL of ultrapure water and 6 mL of ethanol to wash by centrifugation, and then washed twice with alcohol, and the volume was fixed in 2 mL of water.

[0033] The second step, the preparation of Fe 3 o 4 @SiO 2 Microspheres: ultrasonically disperse the above product in 15mL ethanol, add 0.5mL concentrated ammonia water (26%) after ultrasonication for 5 minutes, add 40μL tetraethyl silicate (TEOS) after ultrasonication for 5 minutes, ultrasonically react for 20 minutes, wash with alcohol Three times, washed twice with ...

Embodiment 2

[0037] The first step is to synthesize superparamagnetic ferriferric oxide nanoclusters: sequentially add 0.288g sodium polyacrylate (PAA) and 0.065g ferric chloride to 17mL diethylene glycol (DEG), stir and heat to 220 °C and maintained for one hour. followed by a rapid injection of 1.8 mL of 0.25 mol L -1 The NaOH DEG solution was stirred at 220°C for one and a half hours. After the reaction was completed, 7 mL of ultrapure water and 8 mL of ethanol were added to the reaction liquid for centrifugation washing, and the product was dispersed in 3 mL of water after washing with alcohol three times.

[0038] The second step, the preparation of Fe 3 o 4 @SiO 2 Microspheres: ultrasonically disperse the above product in 20mL ethanol, add 1mL concentrated ammonia water (26%) after ultrasonication for 5 minutes, add 60μL tetraethyl silicate (TEOS) after mechanical stirring for 10 minutes, stir vigorously, react for 30 minutes, alcohol Wash three times, wash twice with water, and...

Embodiment 3

[0042] The first step is to synthesize superparamagnetic ferriferric oxide nanoclusters: add 0.305g sodium polyacrylate (PAA) and 0.098g ferric chloride to 30mL diethylene glycol (DEG) successively, stir and heat to 240 °C and maintained for 1.5 hours. This was followed by a rapid injection of 3 mL of 0.36 mol L -1 The NaOH DEG solution was stirred at 240°C for 1.9 hours. After the reaction was completed, the reaction solution was dilute to 49 mL with ethanol and collected by centrifugation, then 9.5 mL of ultrapure water and 8 mL of ethanol were added for centrifugation washing, and the product was dispersed in 5 mL of water after three alcohol washes.

[0043] The second step, the preparation of Fe 3 o 4 @SiO 2 Microspheres: Ultrasonic disperse the above product in 30mL ethanol, add 3mL concentrated ammonia water (26%) after ultrasonication for 20 minutes, add 100μL tetraethyl silicate (TEOS) after ultrasonication for 16 minutes, ultrasonic reaction for 60 minutes, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com