A method for electrocatalytic degradation of tetracycline in water

An electrocatalytic degradation, tetracycline technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of increased risk, increased cost, increased pathogen resistance, affecting microbial communities, animals and plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

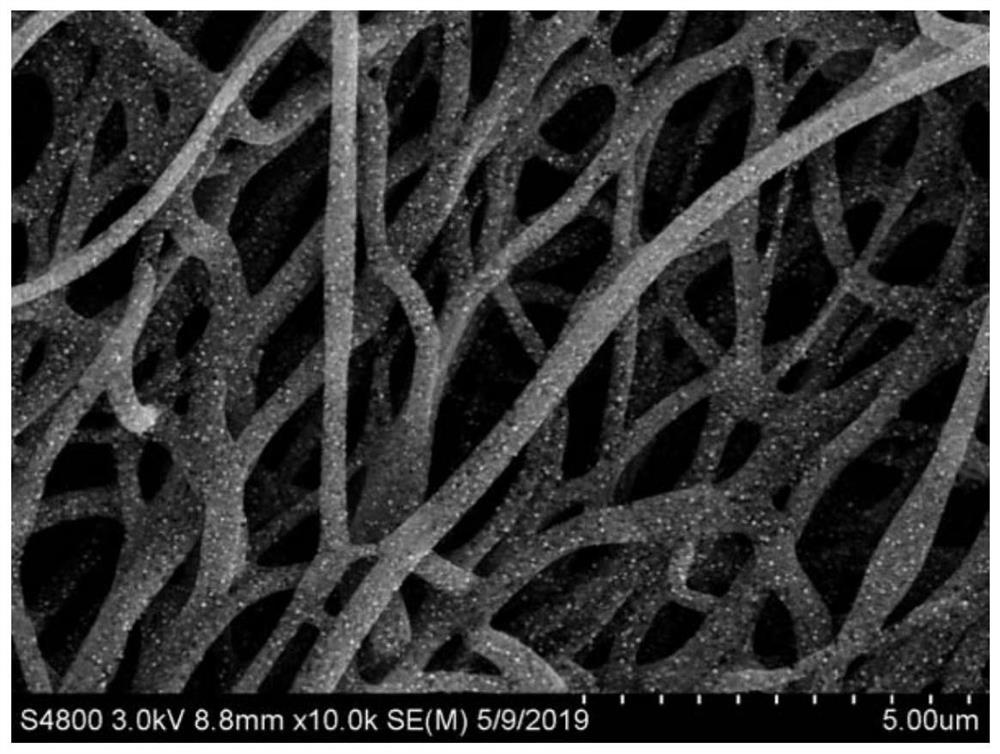

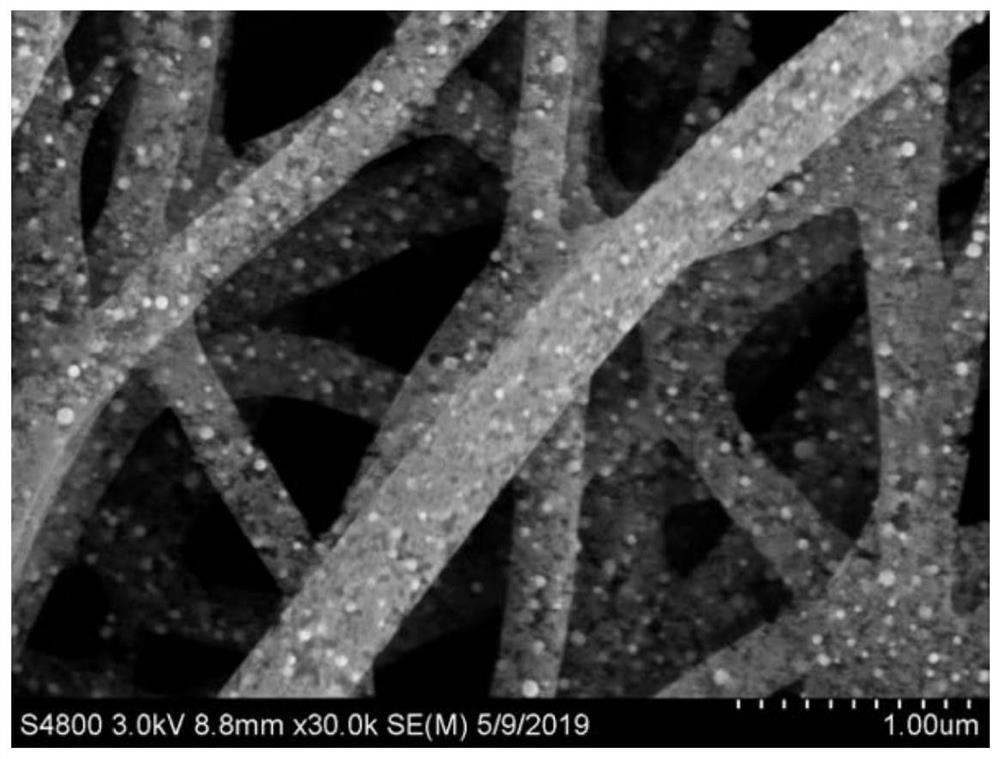

[0024] The preparation method of iron-cobalt alloy carbon nanocomposite fiber is as follows:

[0025] Step 1, preparation is dissolved in the ethanol solution of ferric nitrate and cobalt nitrate, obtains solution A, prepares the ethanol solution that is dissolved in polyvinylpyrrolidone, obtains solution B;

[0026] Wherein, the mass fraction of iron nitrate in solution A is 3.3%, the mass fraction of cobalt nitrate is 1.7%, and in solution B, the mass fraction of polyvinylpyrrolidone (K30, Sinopharm Wokai) is 35.7%;

[0027] Step 2, add 1.5mL of solution A dropwise to 3.5mL of solution B to obtain a mixed solution;

[0028] Step 3, use the mixed solution to carry out high-voltage electrospinning, the parameters of high-voltage electrospinning are voltage 25kV, spinning speed 0.001mm / s, distance between spinning needle and receiver 20cm, and the fiber diameter is 500nm. Vinylpyrrolidone polymer nanofibers;

[0029] Step 4, drying the polyvinylpyrrolidone polymer nanofibers ...

Embodiment 1

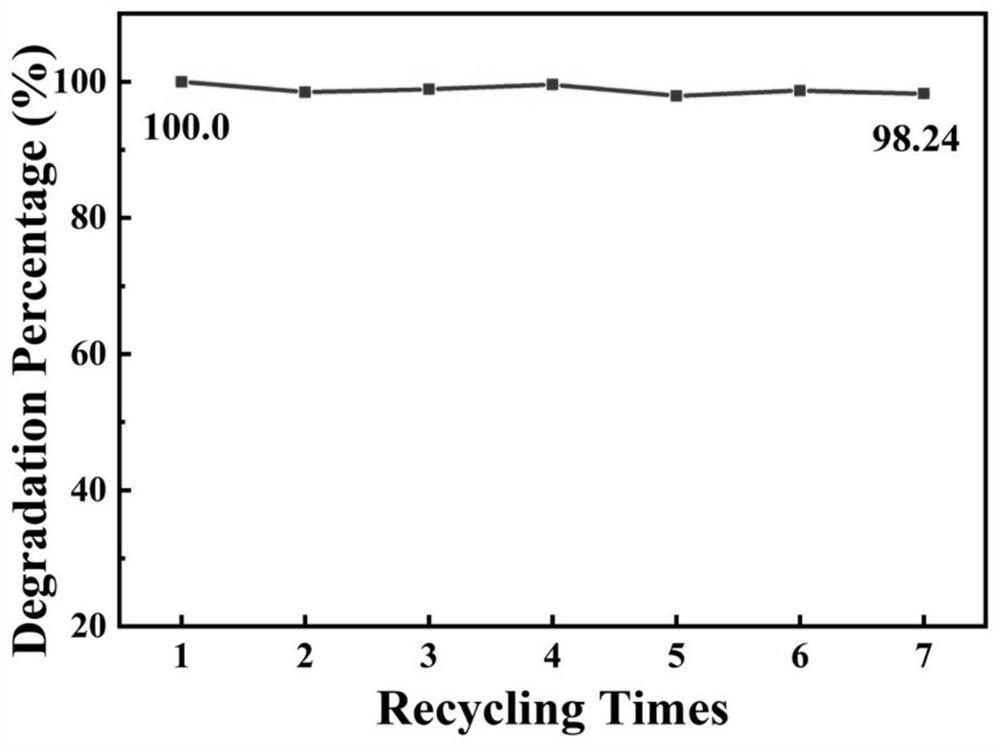

[0036] A method for electrocatalytic degradation of tetracycline in water, the steps are as follows:

[0037] Using a three-electrode system consisting of a composite electrode, a calomel electrode and a platinum wire electrode, electrolyze 20 mL of tetracycline aqueous solution containing 0.1 mol / L sodium sulfate,

[0038] Wherein, the initial concentration of tetracycline in the tetracycline aqueous solution is 30 mg / L, the initial pH value is 7, the voltage applied during electrolysis is constant at 1.0 V, and the electrolysis time is 12 hours.

[0039] After the electrolysis, the absorbance at 356.6 nm was measured with a UV spectrophotometer, and the concentration of tetracycline in the system after the electrolysis was measured through the concentration-absorbance curve obtained in advance, and the degradation rate of tetracycline in this embodiment was calculated to be 94.2%.

Embodiment 2

[0041] A method for electrocatalytic degradation of tetracycline in water, the steps are as follows:

[0042] Using a three-electrode system consisting of a composite electrode, a calomel electrode and a platinum wire electrode, electrolyze 20 mL of tetracycline aqueous solution containing 0.1 mol / L sodium sulfate,

[0043] Wherein, the initial concentration of tetracycline in the tetracycline aqueous solution is 30 mg / L, the initial pH value is 3, the voltage applied during electrolysis is constant at 1.0 V, and the electrolysis time is 12 hours.

[0044] After the electrolysis, the absorbance at 356.6 nm was measured with a UV spectrophotometer, and the concentration of tetracycline in the system after the electrolysis was measured through the concentration-absorbance curve obtained in advance, and the degradation rate of tetracycline in this embodiment was calculated to be 97.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com