V-type polydimethyl siloxane hydrophobic association emulsion polymerization printing thickener and preparation method and application thereof

The technology of polydimethylsiloxane and dimethylsiloxane polyoxyethylene ether is applied in the field of V-type polydimethylsiloxane hydrophobic association emulsion polymerization printing thickener, which can solve the problem of electrolyte resistance. Poor, environmentally unfriendly, poor elution properties, etc., to achieve the effect of good electrolyte resistance, wide application range and good thickening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

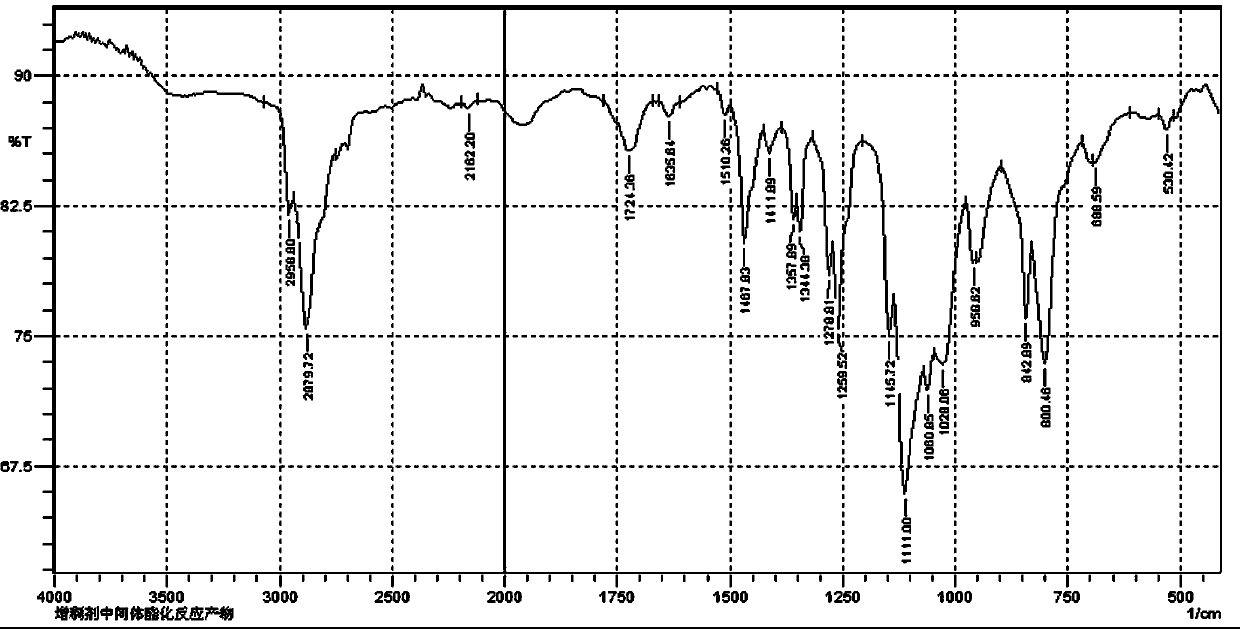

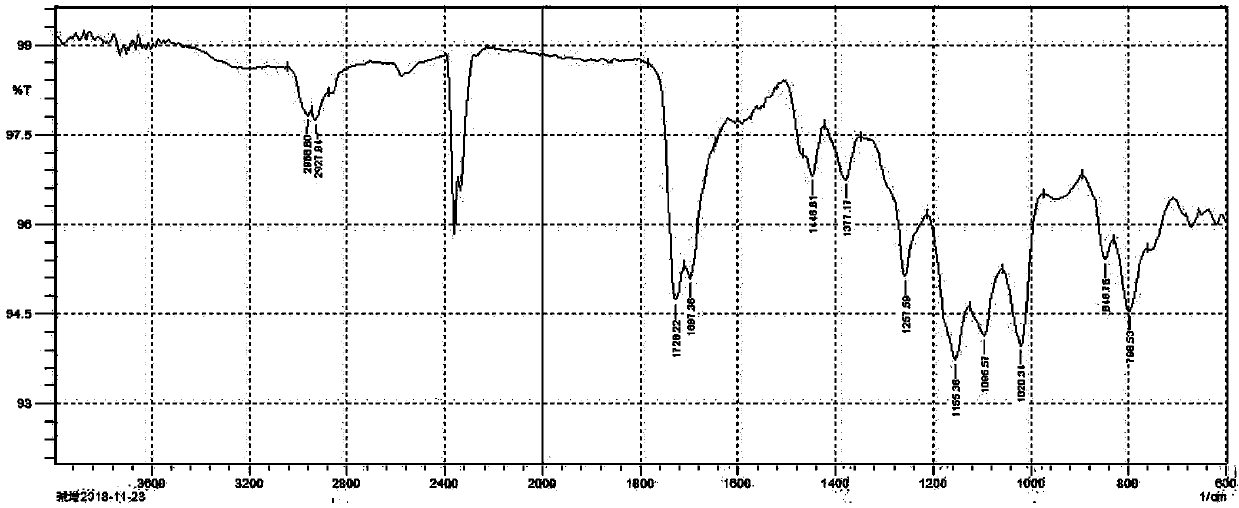

Image

Examples

Embodiment 1

[0036] (1) Pre-emulsion preparation: 1% of m=2, n=2, a=21, R 1 = H, R 2 =H's V-shaped polydimethylsiloxane polyoxyethylene ether monoacrylate, 9.8% methacrylic acid, 17.64% methyl methacrylate, 17.64% butyl methacrylate, 17.64% ethyl acrylate, 17.64% Add butyl acrylate, 17.64% isooctyl acrylate, 1% AEO-9 and deionized water into a three-necked flask, raise the temperature to 60°C, and emulsify for 32 minutes to obtain a pre-emulsion;

[0037] (2) prepare initiator aqueous solution: initiator is added water to make initiator aqueous solution, and described initiator is potassium persulfate;

[0038] (3) Synthesis: Add 1 / 3 of the mixed emulsion in (1) into another three-necked flask, and heat up to 60°C; under nitrogen protection, add 1 / 3 of the aqueous initiator solution to initiate polymerization, and drop the remaining 2 / 3 Mix emulsion and initiator aqueous solution, add drop time for 2 hours, continue to react at 65°C for 4 hours after dropwise addition; after reaction, c...

Embodiment 2

[0041] (1) Pre-emulsion preparation: 5% of m=2, n=20, a=21, R 1 = H, R 2 = Me's V-shaped polydimethylsiloxane polyoxyethylene ether monoacrylate, 26.91% acrylic acid, 10.47% methyl methacrylate, 14.65% butyl methacrylate, 25.11% ethyl acrylate, 12.56% butyl acrylate Add ester, 3% acrylamide, 0.3% N,N-methylenebisacrylamide, 1% K12, 1% AES and deionized water into a three-necked flask, raise the temperature to 65°C, and emulsify for 31 minutes to obtain a pre-emulsion;

[0042] (2) prepare initiator aqueous solution: initiator is added water to make initiator aqueous solution, and described initiator is ammonium persulfate;

[0043] (3) Synthesis: Add 1 / 3 of the mixed emulsion in (1) into another three-necked flask, and heat up to 65°C; under nitrogen protection, add 1 / 3 of the aqueous initiator solution to initiate polymerization, and drop the remaining 2 / 3 Mix emulsion and initiator aqueous solution, add drop time for 2.5h, continue to react at 70°C for 3h after dropwise a...

Embodiment 3

[0045] (1) Pre-emulsion preparation: 10% of m=2, n=20, a=53, R 1 = Me,R 2 = Me's V-shaped polydimethylsiloxane polyoxyethylene ether monoacrylate, 21.18% methacrylic acid, 21.17% acrylic acid, 8.47% butyl methacrylate, 25.41% ethyl acrylate, 8.47% butyl acrylate, Add 2% acrylamide, 0.1% diallyl phthalate, 0.2% N,N-methylenebisacrylamide, 3% K12 and deionized water into a three-necked flask, raise the temperature to 70°C, and emulsify for 30 minutes to obtain pre-emulsion;

[0046] (2) prepare initiator aqueous solution: add water to initiator and make initiator aqueous solution, described initiator is sodium bisulfite and potassium persulfate composition;

[0047] (3) Synthesis: Add 1 / 3 of the mixed emulsion in (1) into another three-necked flask, and heat up to 70°C; under nitrogen protection, add 1 / 3 of the aqueous initiator solution to initiate polymerization, and drop the remaining 2 / 3 Mix emulsion and initiator aqueous solution, add dropwise for 2.5 hours, continue re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com