Polyaniline corrosion inhibitor and preparation method thereof

A technology of corrosion inhibitor and polyaniline, which is applied in the field of polyaniline corrosion inhibitors and its preparation, can solve the problems of operator safety hazards, difficulties in the preparation of corrosion inhibitors, and unsustainable protection effects, etc., to achieve long-lasting protection effects and improve Solubility and the effect of many adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

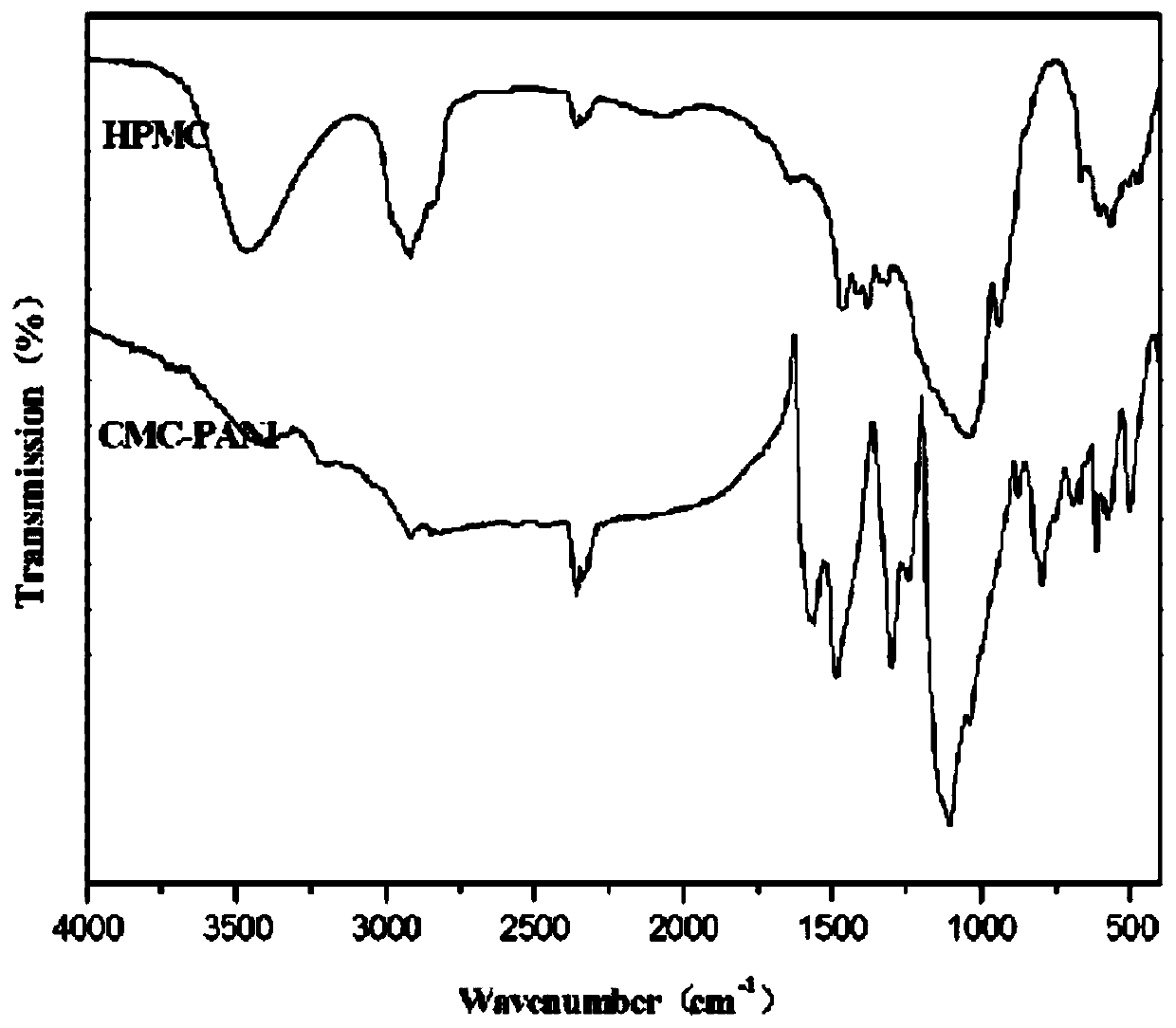

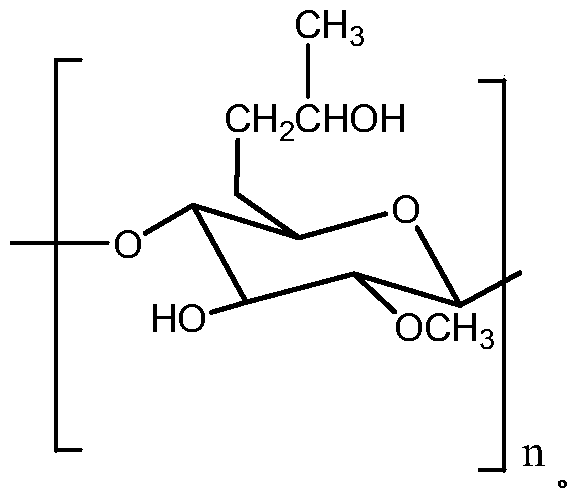

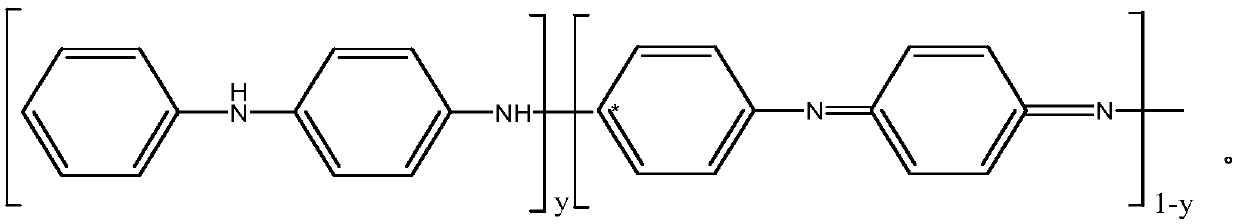

[0033] The polyaniline corrosion inhibitor of the invention is prepared by using hydroxypropyl methylcellulose, ammonium persulfate, aniline and water in a proper proportion. The preparation method of polyaniline corrosion inhibitor comprises the steps:

[0034] (1) According to the ratio that the molar ratio of hydroxypropyl methylcellulose to water is 1:350~400, weigh the dry hydroxypropyl methylcellulose, add it into the water placed in the reaction vessel, and make it its dissolution;

[0035] (2) Oxidation reaction: according to the mol ratio of hydroxypropyl methylcellulose and ammonium persulfate is the ratio of 1: 2.84~4.32, first ammonium persulfate is dissolved in the water of the same volume in step (1), then in the magnetic Add the ammonium persulfate solution dropwise to the reactor under stirring, heat it to 60°C under the stirring condition of 100-300r / min to react for 6-12h, then cool to room temperature, and transfer to the dropping funnel middle;

[0036] ...

Embodiment 1

[0042] Weigh 6g of hydroxypropyl cellulose, dissolve it in 50ml of water in the reactor, and stir (magnet) to dissolve it. Oxidation reaction: Dissolve 4.8g of ammonium persulfate in 50ml of water, add the ammonium persulfate solution to the cellulose aqueous solution drop by drop under magnetic stirring, heat it to 60°C for 6h under the stirring condition of 200r / min, and then cool it down to room temperature and transferred to the dropping funnel. Polymerization reaction: Add 3ml of aniline to 48ml of distilled water, sonicate for 10min, cool down to 0-5°C, add the cellulose solution prepared in advance into the reactor under stirring with a constant pressure dropping funnel (about one drop per second) speed). Keep the temperature of the reaction system at 0-5°C, and react for 12 hours.

[0043] After the reaction was completed, it was filtered, the filter cake was washed with acetone, and vacuum-dried at 60° C. for 2 hours to obtain cellulose-doped polyaniline. The corro...

Embodiment 2

[0045] Weigh 6g of hydroxypropyl cellulose, dissolve it in 50ml of water in the reactor, and stir (magnet) to dissolve it. Oxidation reaction: Dissolve 6g of ammonium persulfate in 50ml of water, add the ammonium persulfate solution to the cellulose aqueous solution drop by drop under magnetic stirring, heat it to 60°C for 6 hours under stirring, then cool to room temperature, move to in the dropping funnel. Polymerization reaction: Add 3ml of aniline to 48ml of distilled water, sonicate for 10min, cool down to 0-5°C, add the cellulose solution prepared in advance into the reactor under stirring with a constant pressure dropping funnel (about one drop per second) speed). Keep the temperature of the reaction system at 0-5°C, and react for 12 hours.

[0046] After the reaction was completed, it was filtered, the filter cake was washed with acetone, and vacuum-dried at 60° C. for 2 hours to obtain cellulose-doped polyaniline. The corrosion inhibition efficiency was measured by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com