TaN coating and preparation method thereof and application

A coating, face-centered cubic technology, applied in the field of magnetron sputtering, achieves the effects of high hardness, good oxidation resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] As an aspect of the technical solution of the present invention, it relates to a method for preparing a TaN coating, which includes:

[0027] provide a substrate;

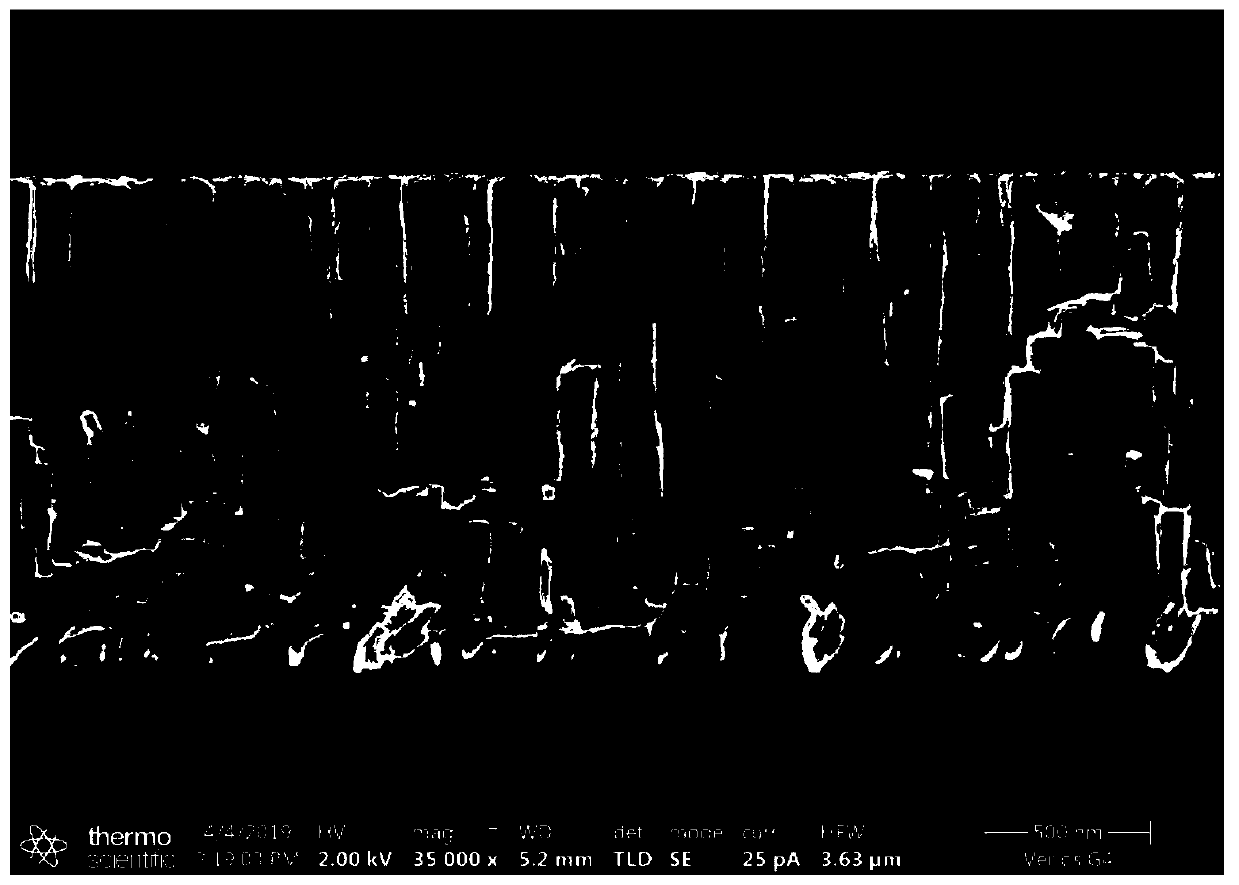

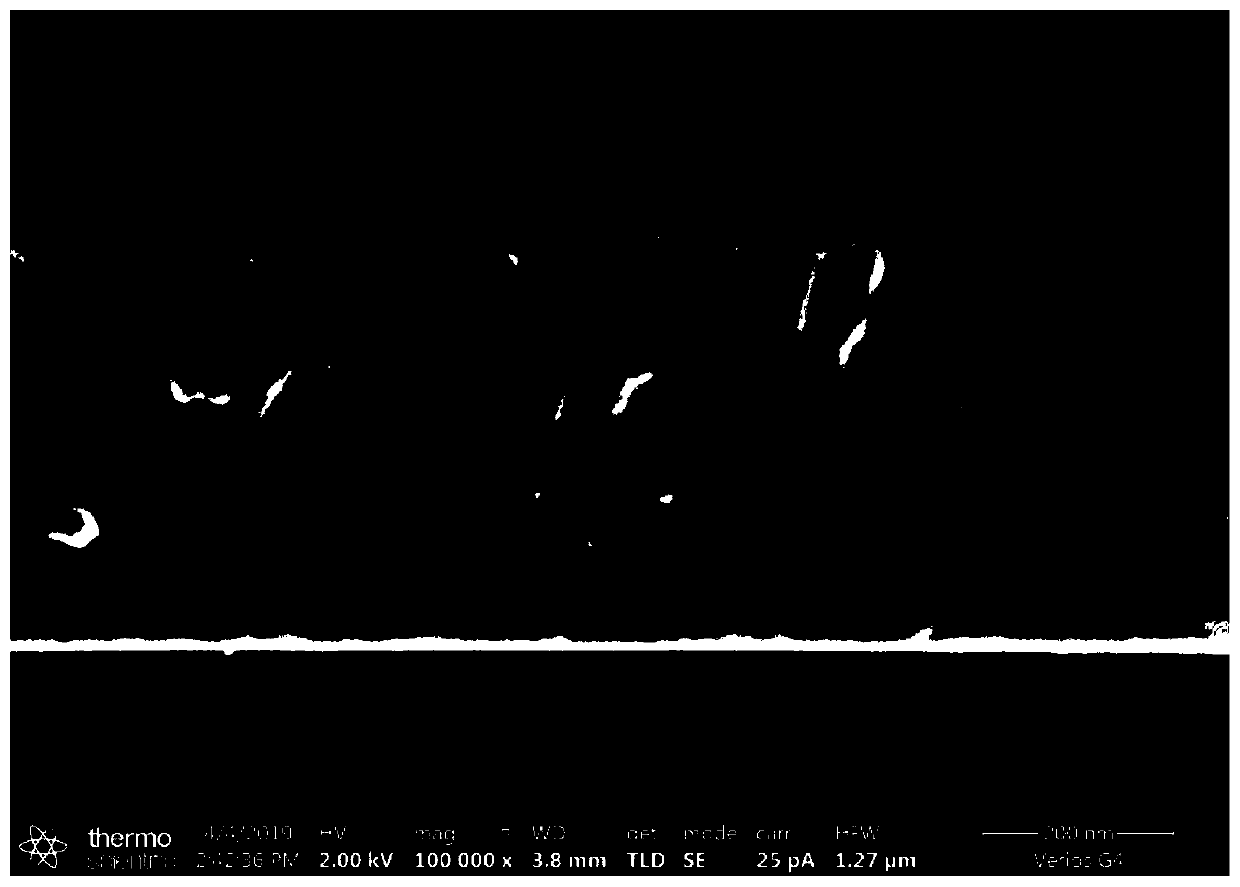

[0028] Using magnetron sputtering technology, using Ta pure metal target as target material, nitrogen and protective gas as working gas, applying negative bias voltage to the substrate, applying target electric rate to Ta pure metal target, and depositing on the surface of the substrate to form TaN coating, the TaN coating has a face-centered cubic crystal structure with (200) as the preferred orientation, a face-centered cubic crystal structure or an amorphous structure with (111) as the preferred orientation;

[0029] The process conditions adopted by the magnetron sputtering technology include: the air pressure in the reaction chamber is 5×10 -3 Pa~6×10 -3 Pa, the target power applied to the Ta pure metal target is 3-3.5kW, the target voltage is 430-450V, the deposition bias is -100V--120V, the temperat...

Embodiment 1

[0053] A method for preparing a TaN coating in this embodiment adopts magnetron sputtering technology, the thickness of the TaN coating is about 1.5 μm, and mainly includes the following steps:

[0054] (1) Perform mechanical grinding and polishing on the surface of the titanium alloy sample to be plated, and then perform ultrasonic cleaning twice with acetone and alcohol respectively, and the ultrasonic time is 15 minutes each.

[0055] (2) Put the cleaned sample into the cavity, vacuumize to 5×10 -3 mbar, while heating, the heating temperature is 400°C.

[0056] (3) Target sputtering and sample etching. The target material was cleaned by sputtering for 5 minutes, and the titanium alloy sample was ion-etched for 15 minutes, and the bias voltage used for sub-etching was 1200V.

[0057] (4) Prepare and deposit TaN coating. A Ta metal target (purity 99.99wt.%) is used, high-purity nitrogen and argon are used as the gas, the flow rate of the argon gas is 240 sccm, and the flow...

Embodiment 2

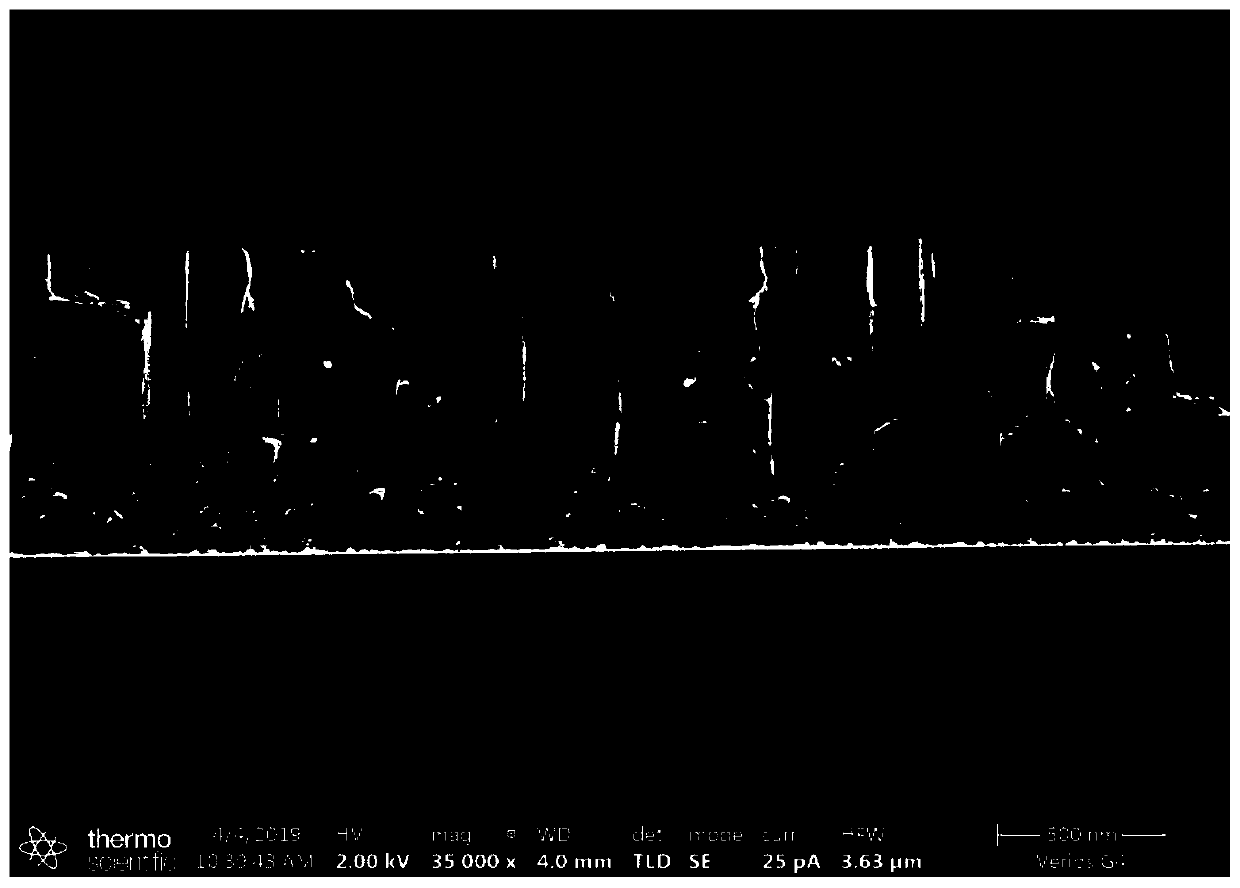

[0060] A kind of preparation method of TaN coating in the present embodiment adopts magnetron sputtering technology, and the thickness of described TaN coating is about 900nm, mainly comprises the following steps:

[0061] (1) Perform mechanical grinding and polishing on the surface of the titanium alloy sample to be plated, and then perform ultrasonic cleaning twice with acetone and alcohol respectively, and the ultrasonic time is 15 minutes each.

[0062] (2) Put the cleaned sample into the cavity, vacuumize to 6×10 -3 mbar, while heating, the heating temperature is 420°C.

[0063] (3) Target sputtering and sample etching. The target material was cleaned by sputtering for 5 minutes, and the titanium alloy sample was ion-etched for 15 minutes, and the bias voltage used for sub-etching was 1200V.

[0064] (4) Prepare and deposit TaN coating. A Ta metal target (purity 99.99wt.%) is used, high-purity nitrogen and argon are used as gas, the flow rate of argon gas is 160 sccm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com