Synthesis method of nanometer needle-like ZSM-11 and mixed-crystal molecular sieve thereof

A technology of ZSM-11 and synthesis method, which is applied in the field of molecular sieves, can solve the problem of long micropore diffusion path, achieve the effect of strong operation purpose, controllable technology and cost, and shorten the intracrystalline micropore diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Add 173g of distilled water, 2.05g of aluminum sulfate, 4.08g of aluminum isopropoxide, 5.6g of sulfuric acid, 12.7g of tetrapropylammonium hydroxide, 29g of tetrabutylammonium bromide, and 54g of dodecyltrimethylammonium bromide After being placed in the hydrothermal synthesis kettle, stir evenly; slowly add 19.3g of silica sol with a mass fraction of 30% drop by drop under stirring, stir evenly, then add 18g of sodium hydroxide, and then seal the synthesis kettle; at a temperature of 50°C And under the condition of stirring speed 120r / min, aging treatment was carried out to synthetic solution for 32 hours, then down to room temperature, and open the kettle lid;

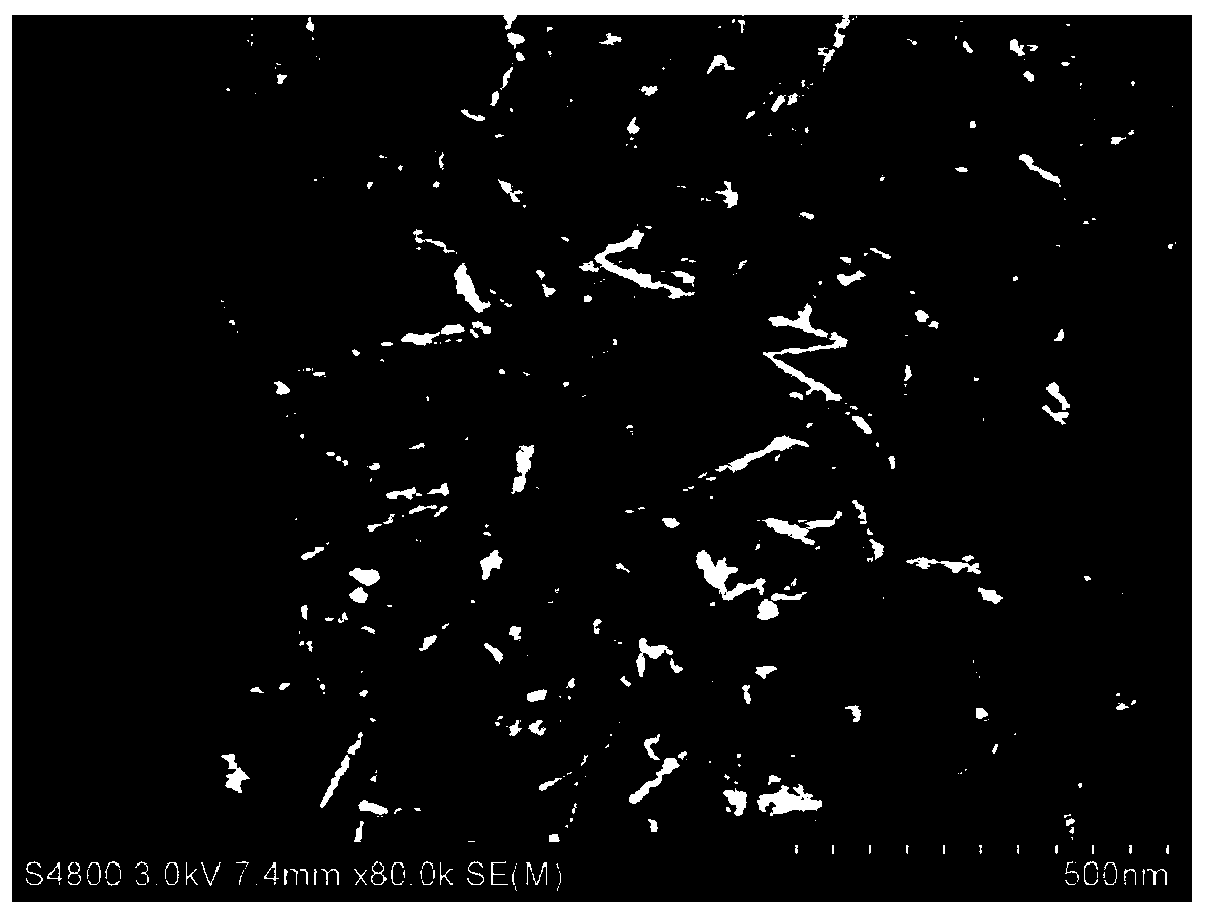

[0024] 2) After adding 308g of methanol to the synthesis liquid after aging treatment, seal the synthesis tank, crystallize at a temperature of 160°C and a stirring rate of 500r / min for 120 hours, cool to room temperature, discharge, wash, and separate , dried and roasted to obtain acicular ZSM-11 molecula...

Embodiment 2

[0026] 1) Mix 21.6g distilled water, 0.06g pseudoboehmite, 0.02g sodium metaaluminate, 1.8g hydrochloric acid, 5.3g tetrapropylammonium bromide, 3.08g dodecyltrimethylammonium bromide, 3.36g After tetradecyltrimethylammonium bromide is added in the hydrothermal synthesis kettle, stir evenly; under stirring state, slowly add 37.4g of water glass with a mass fraction of 38% and 3g of silicon oxide powder, stir evenly, and then add 16g Potassium hydroxide, and then seal the synthesis kettle; under the condition that the temperature is 12°C and the stirring rate is 900r / min, the synthesis liquid is aged for 149 hours, cooled to room temperature, and the lid of the kettle is opened;

[0027] 2) After adding 115g of ethanol and 75g of formaldehyde to the synthesis liquid after aging treatment, seal the synthesis kettle, crystallize at a temperature of 100°C and a stirring rate of 900r / min for 300 hours, cool to room temperature, discharge, Washing, separating, drying and calcining t...

Embodiment 3

[0029] 1) 1440g distilled water, 0.125 aluminum nitrate, 32g nitric acid, 320g tetraethylammonium hydroxide, 200g tetrabutylammonium hydroxide, 125g cetyltrimethylammonium bromide are added in the hydrothermal synthesis kettle, after stirring evenly, in Slowly add 20.8g tetraethyl orthosilicate dropwise under stirring state, stir evenly, then add 56g potassium hydroxide, and then seal the synthesis kettle; Aging treatment for 0.1 hour, down to room temperature, and open the lid of the kettle;

[0030] 2) After adding 0.29g of acetone, 0.3g of propanol, and 0.92g of glycerol to the synthesis solution after aging treatment, seal the synthesis kettle, and crystallize for 26 hours at a temperature of 200°C and a stirring rate of 60r / min After that, it is cooled to room temperature, discharged, washed, separated, dried and calcined to obtain a needle-shaped ZSM-11 molecular sieve with a needle-shaped cross-sectional diameter of about 3 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com