Method for increasing yield of corn starch with biological enzymes

A corn starch and biological enzyme technology, which is applied in the field of corn starch processing, can solve the problems of reduced corn starch yield, reduced usage of sulfur dioxide, health effects, etc. The effect of improving hygiene standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

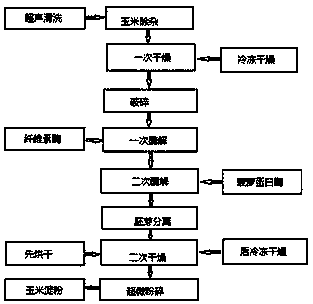

Method used

Image

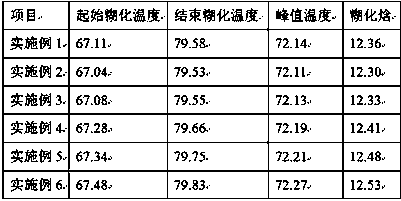

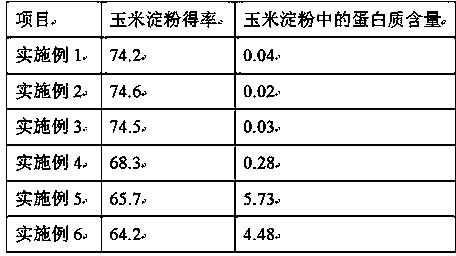

Examples

Embodiment 1

[0024] A method for increasing cornstarch yield by biological enzymes, comprising the following steps:

[0025] (1) Impurity removal: sieve, winnow and magnetically separate the corn kernels to remove the obvious impurities in the corn kernels, and then ultrasonically clean the corn kernels with clean water at a temperature of 40°C, an ultrasonic frequency of 24kHz, and an ultrasonic time of For 20 minutes, remove the dust attached to the surface of the corn kernels, improve the hygiene standards of the corn kernels, and obtain clean corn;

[0026] (2) Primary drying: put the clean corn in a freeze dryer, the freezing temperature is -47°C, the shelf heating temperature is 36°C, and freeze-dry to a moisture content of 4-6%, so that the moisture contained in the corn kernels Quick freezing is conducive to the separation of various structures in corn kernels, and can promote the separation of fiber layers and germs from starch. At the same time, it can quickly volatilize the wate...

Embodiment 2

[0034] A method for increasing cornstarch yield by biological enzymes, comprising the following steps:

[0035] (1) Impurity removal: sieve, winnow and magnetically separate the corn kernels to remove the obvious impurities in the corn kernels, and then ultrasonically clean the corn kernels with clean water at a temperature of 43°C, an ultrasonic frequency of 25kHz, and an ultrasonic time of 23 minutes, remove the dust attached to the surface of the corn kernels, improve the hygiene standards of the corn kernels, and get clean corn;

[0036] (2) Primary drying: put the clean corn in a freeze dryer, the freezing temperature is -48°C, the shelf heating temperature is 37°C, and freeze-dry until the water content is 4~6%, so that the moisture contained in the corn kernels Quick freezing is conducive to the separation of various structures in corn kernels, and can promote the separation of fiber layers and germs from starch. At the same time, it can quickly volatilize the water in ...

Embodiment 3

[0044] A method for increasing cornstarch yield by biological enzymes, comprising the following steps:

[0045] (1) Impurity removal: sieve, winnow and magnetically separate the corn kernels to remove the obvious impurities in the corn kernels, and then ultrasonically clean the corn kernels with clean water at a temperature of 45°C, an ultrasonic frequency of 26kHz, and an ultrasonic time of 25 minutes, remove the dust attached to the surface of the corn kernels, improve the hygiene standards of the corn kernels, and get clean corn;

[0046] (2) Primary drying: put the clean corn in a freeze dryer, the freezing temperature is -49°C, the shelf heating temperature is 38°C, and freeze-dry until the moisture content is 4-6%, so that the moisture contained in the corn kernels Quick freezing is conducive to the separation of various structures in corn kernels, and can promote the separation of fiber layers and germs from starch. At the same time, it can quickly volatilize the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com