Preparation method of magnesium aluminum silicon microcrystalline glass for LTCC packaging materials

A technology of glass-ceramics and encapsulation materials, which is applied in the field of new materials, can solve problems such as high sintering temperature and poor matching of thermal expansion coefficients, and achieve the effects of excellent performance, simple and reasonable preparation method, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

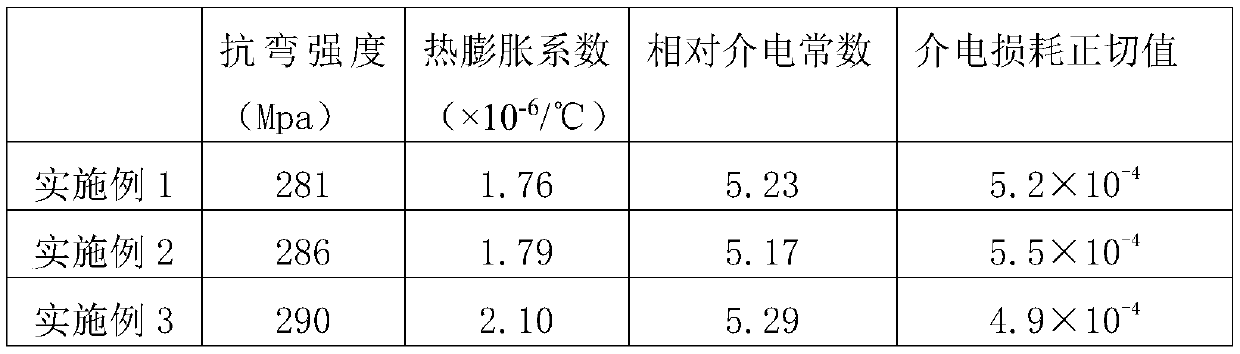

Examples

Embodiment 1

[0033] (1) Ingredients: prepare the raw materials of magnesium-aluminum-silicon glass-ceramics, weigh them, and mix the raw materials after weighing to obtain a mixture;

[0034] The raw material of the magnesium-aluminum-silicate glass-ceramic is composed of the following components in parts by mass: 33 parts of magnesium carbonate, 32 parts of aluminum oxide, 32 parts of silicic acid, and 3 parts of titanium dioxide;

[0035] (2) Primary ball milling: put deionized water, zirconium balls, and the mixture into a nylon tank for ball milling, and the ball milling time is 2 hours;

[0036] (3) Drying and sieving: After the ball milling is completed, dry the obtained mixed slurry at a drying temperature of 100° C. and a drying time of 2 hours to obtain a dry powder; take out the dry powder and pass through a 40-mesh sieve;

[0037] (4) Melting and water quenching: take the sieved dry powder and put it into a crucible at a temperature of 1500°C, melt for 1 hour, discharge gas, and...

Embodiment 2

[0045] (2) Ingredients: prepare the raw materials of magnesium-aluminum-silicon glass-ceramic, weigh them, and mix the raw materials after weighing to obtain a mixture;

[0046] The raw material of the magnesium-aluminum-silicate glass-ceramics consists of the following components in parts by mass: 35 parts of magnesium carbonate, 32 parts of aluminum oxide, 30 parts of silicic acid, and 3 parts of titanium dioxide;

[0047] (2) Primary ball milling: put deionized water, zirconium balls, and the mixture into a nylon tank for ball milling, and the ball milling time is 2 hours;

[0048] (3) Drying and sieving: After the ball milling is completed, dry the obtained mixed slurry at a drying temperature of 100° C. and a drying time of 2 hours to obtain a dry powder; take out the dry powder and pass through a 40-mesh sieve;

[0049] (4) Melting and water quenching: take the sieved dry powder and put it into a crucible at a temperature of 1500°C, melt for 1.5 hours, discharge gas, and...

Embodiment 3

[0057] (3) Ingredients: prepare the raw materials of magnesium-aluminum-silicon glass-ceramics, weigh them, and mix the raw materials after weighing to obtain a mixture;

[0058] The raw material of the magnesium-aluminum-silicate glass-ceramics consists of the following components in parts by mass: 30 parts of magnesium carbonate, 35 parts of aluminum oxide, 32 parts of silicic acid, and 3 parts of titanium dioxide;

[0059] (2) Primary ball milling: put deionized water, zirconium balls, and the mixture into a nylon tank for ball milling, and the ball milling time is 2 hours;

[0060] (3) Drying and sieving: After the ball milling is completed, dry the obtained mixed slurry at a drying temperature of 100° C. and a drying time of 2 hours to obtain a dry powder; take out the dry powder and pass through a 40-mesh sieve;

[0061] (4) Melting and water quenching: put the sieved dry powder into a crucible at a temperature of 1500°C, melt for 1 hour, discharge gas, and water quench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com