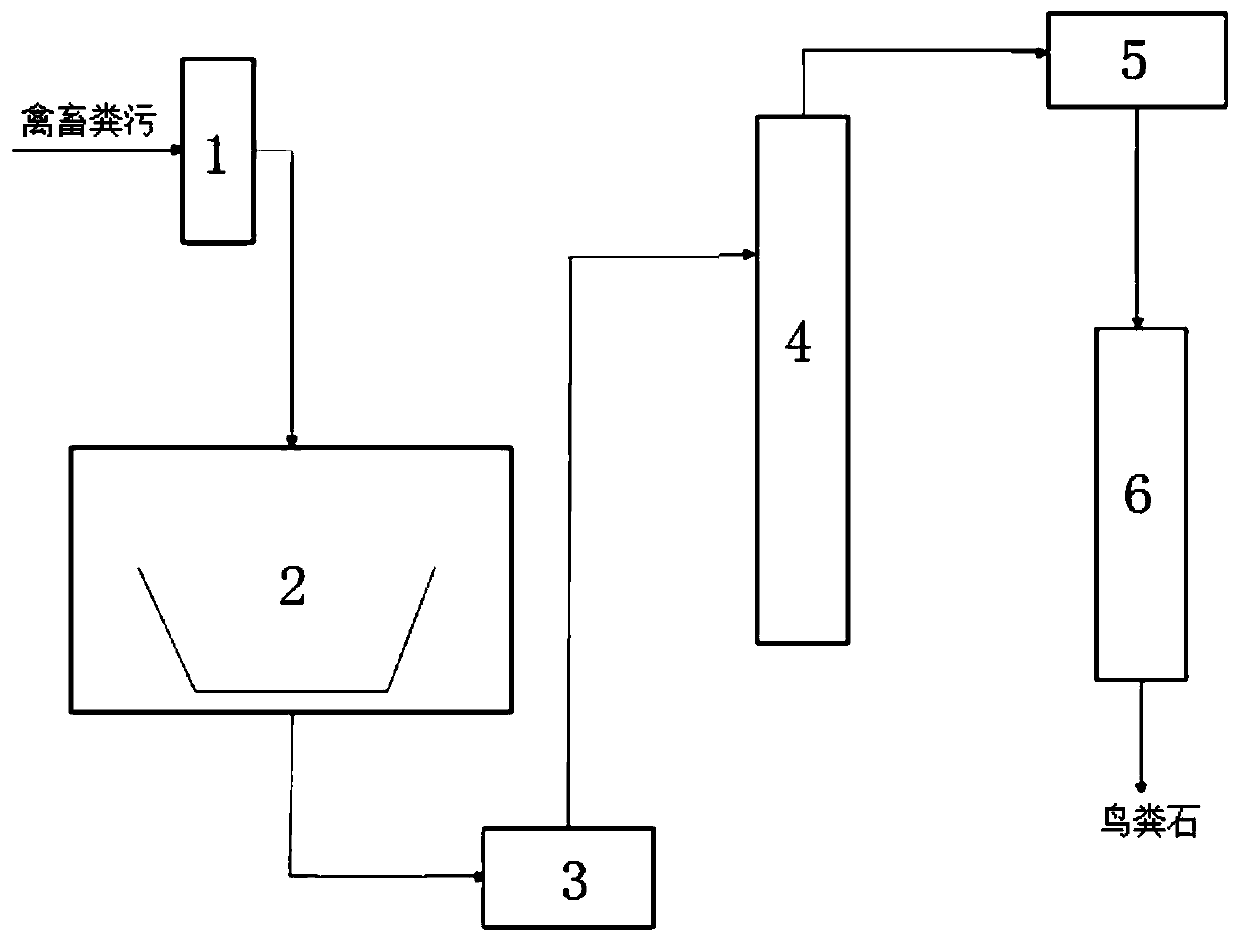

Method for recovering and purifying struvite from livestock and poultry manure

A technology for struvite and manure, which is applied in the field of wastewater treatment and resource recovery, can solve the problems of difficulty in adding pure struvite, long dissolution time, slow recovery speed, etc., and achieve high batch production efficiency, low economic cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

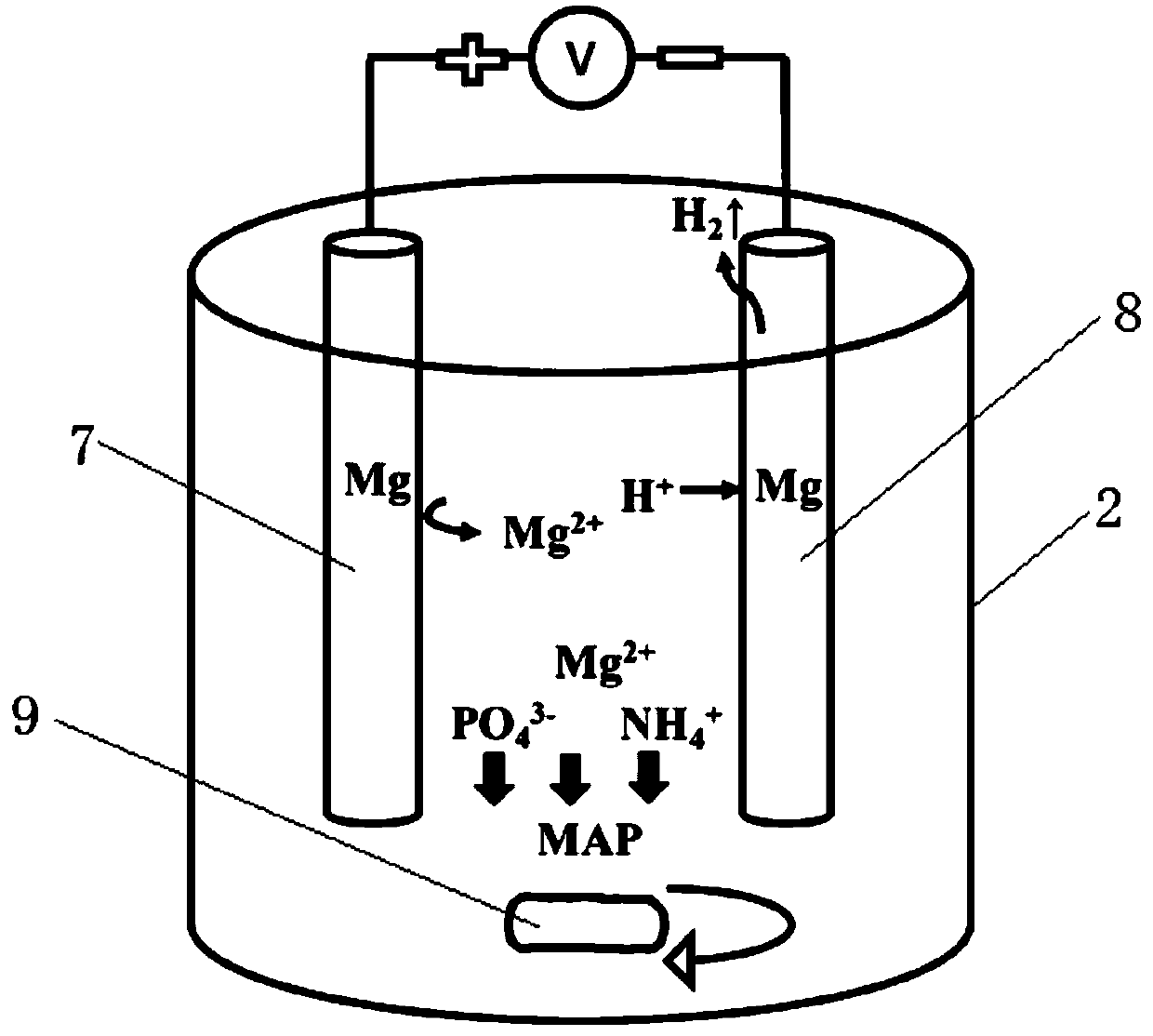

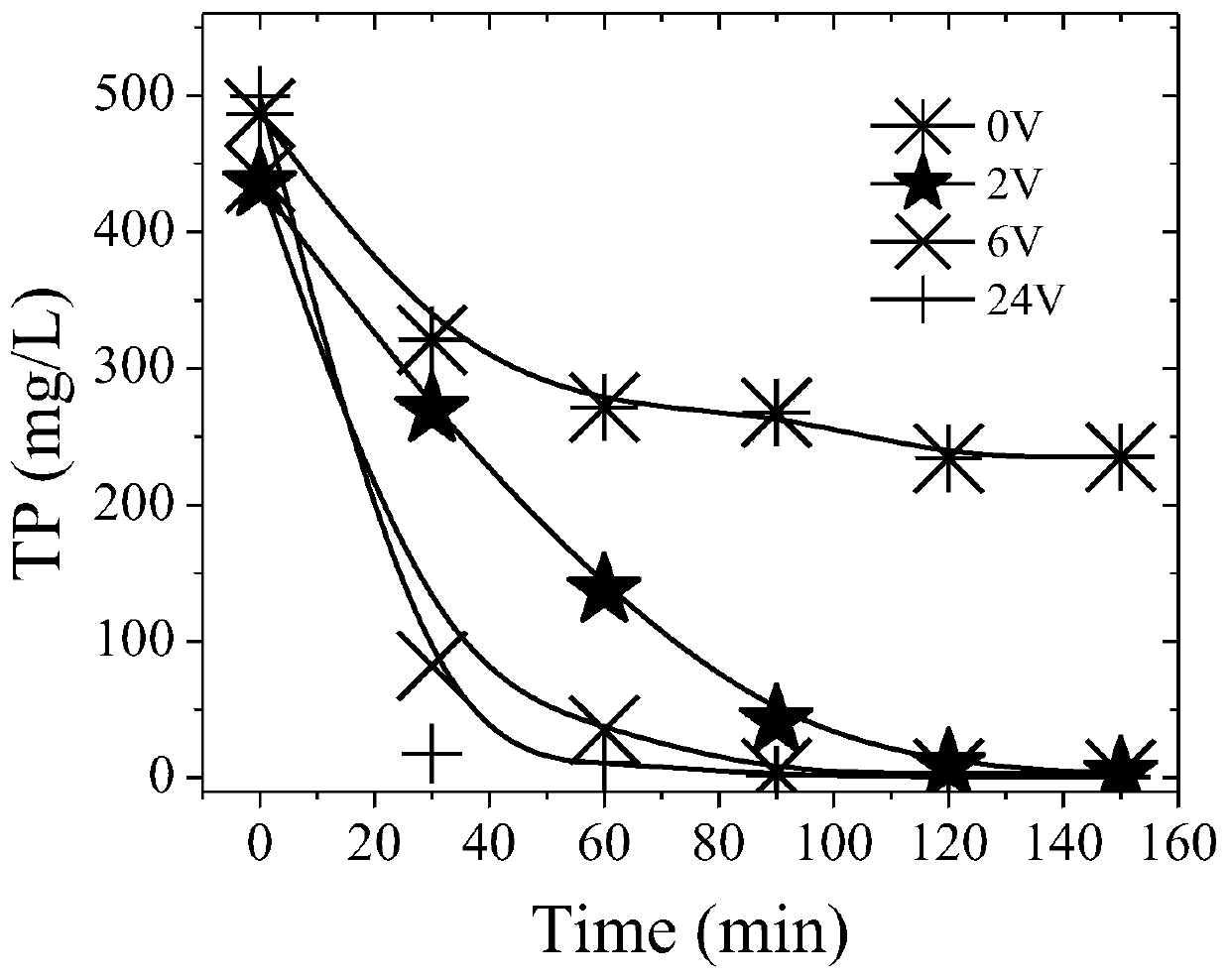

[0050] S1: Put the livestock and poultry manure into the anaerobic reactor that has been successfully started and continuous flow, and take 500mL of the manure digestion solution in the system; the ammonia nitrogen (NH 4 - N) concentration is 3994.05mg / L, total phosphorus (TP) concentration is 521.502mg / L, and the substance concentration ratio is N:P=7.659:1.

[0051] S2: Pass the excrement digestion liquid into figure 2 In the electrolysis reaction stirring cell shown, magnesium is selected as the cathode and anode of the electrode in the electrolysis reaction stirring cell, and DC voltage is used to perform electrolysis under the condition of agitator stirring; the distance between the two electrodes is 6cm, and the voltage is controlled at 0V at the same time, at 2000rpm Stirring, the hydraulic retention time is 150min, and the pH is not adjusted.

[0052] S3: The solution after the electrolysis reaction is passed into the sedimentation tank for static precipitation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com