Battery diaphragm material and its preparation method and application

A battery separator and coating material technology, applied in fuel cells, battery electrodes, secondary batteries, etc., can solve problems such as failure, low capacity of lithium-ion batteries, deterioration of negative electrode performance, etc., to improve Coulomb efficiency, improve cycle performance, The effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a battery diaphragm coating material of the present invention, comprising: dissolving PVDF and covalent organic framework material in N-methylpyrrolidone and stirring evenly; said PVDF, covalent organic framework material and N-methylpyrrolidone The mass ratio of pyrrolidone is 20:(70-85):(5-10). Among them, PVDF has good chemical stability and temperature characteristics, excellent mechanical properties and processability, and has a positive effect on improving bonding performance. If other types of resins are used instead of PVDF, such as sodium hydroxymethyl cellulose (CMC) and styrene-butadiene rubber (SBR), if CMC is too brittle, it will cause the pole piece to drop powder, and the dispersion effect of SBR is not good, which will affect the cycle performance of the material. negative impacts.

[0027] Preferably, the organic solvent is a mixed solution of 1,4-dioxane and mesitylene.

[0028] Specifically, the covalent organic framework mate...

Embodiment 1

[0037] Prepare covalent organic framework materials (Covalent Organic Frameworks, COFs), by mass percentage, its raw material components are as follows:

[0038] 1,3,5-tris(4-aminophenyl)benzene (TPB) 54.6%,

[0039] 2,5-dimethoxy-1,4-dicarboxybenzene (DMTP) 45.4%,

[0040] Concrete preparation steps are as follows:

[0041] Dissolve 1,3,5-tris(4-aminophenyl)benzene (TPB) and 2,5-dimethoxy-1,4-dimethylaldehydebenzene (DMTP) in organic solvent 1,4-dioxane Ring and mesitylene, ultrasonic, control ultrasonic time is 5-10 minutes. Add 1-3% acetic acid. Then, under an inert protective atmosphere, the mixture was reacted at 120° C. for 3 days, and the obtained product was a yellow solid. Finally, the obtained yellow solid was repeatedly washed with 1,4-dioxane, tetrahydrofuran and absolute ethanol for 2-3 times, and then dried in vacuum for 12 hours. The stated percentages are all mass percentages.

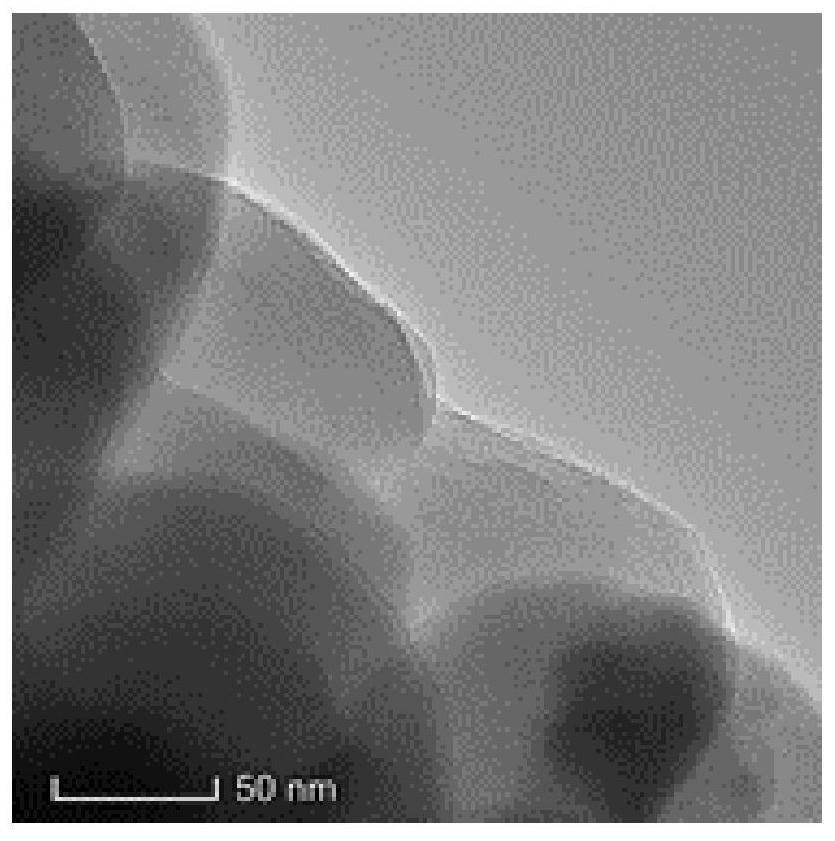

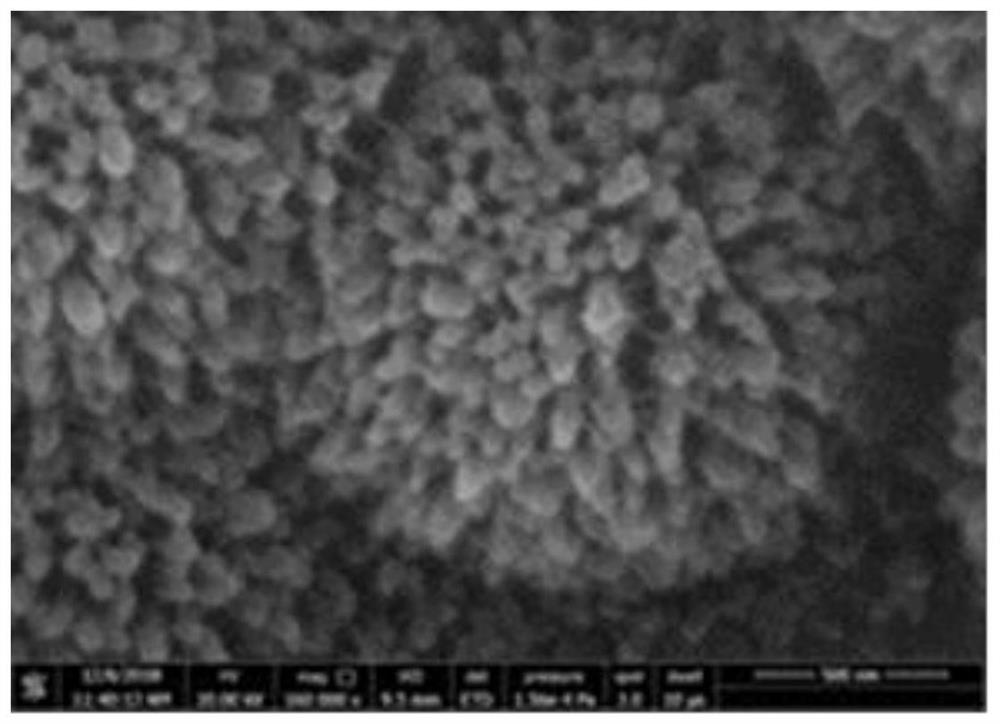

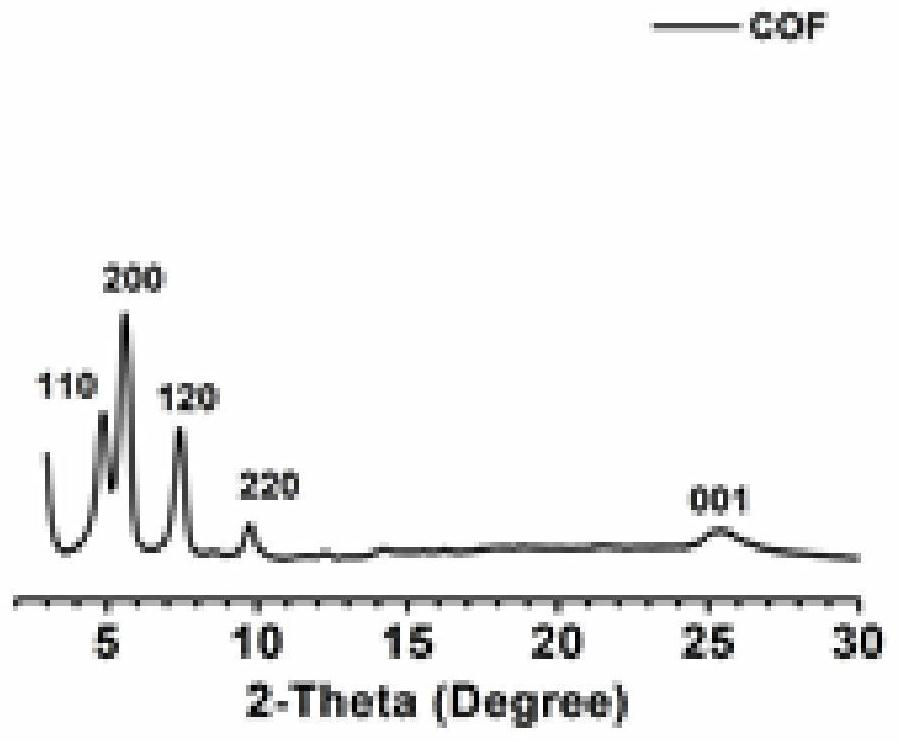

[0042] After detection, the transmission electron microscope scanning image (...

Embodiment 2

[0050] Example 2 Application of COFs Modified Diaphragm: NCM811 as a cathode material for a lithium ion battery diaphragm

[0051] The COFs modified diaphragm prepared in Example 1 was cut into a diameter of 18 mm, used as a diaphragm for a lithium-ion battery, and NCM811 was used as a positive electrode material to assemble the battery.

[0052] After the separator was assembled into a battery, the cyclic voltammetry was measured. Figure 4 It is the cycle diagram of NCM811. It can be seen from the comparison that at room temperature, the half-cell prepared by mixing the separator synthesized by COFs and the half-cell prepared by unmixed CoFs are charged and discharged three times at a rate of 0.3C. The specific capacity Both remain at about 200mAh / g, and the Coulombic efficiency is 100% after 3 cycles, and when the two batteries are charged and discharged 150 times at a rate of 1C, it is found that the specific capacity of the half-cell prepared by this method is between 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com