Copper-based alloy catalyst and preparation method and application thereof

A technology of copper-based alloy and catalyst, which is applied in the field of copper-based alloy catalyst and its preparation, can solve the problems of easy loss of precious metals, increase of production cost, and decrease of conversion rate, and achieve the effects of reducing production cost, improving performance, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Dissolve 13.4g of copper chloride, 11.1g of indium chloride and 5g of butyltrimethylimidazole acetate in 120ml of deionized water, stir and mix evenly;

[0042] 2) Add 100g of 20-mesh columnar activated carbon to the mixture in step 1), impregnate it with ultrasonic (0.5kW) at 25°C for 4h, and then heat it at 110°C and 12μW / (cm 2 Bake for 10 h under blue light irradiation conditions with *nm) intensity to obtain a completely dry catalyst;

[0043] 3) The catalyst obtained in step 2) is placed in a mixed gas of hydrogen and helium passing through 5ml / min (the volume flow ratio of hydrogen and helium is 0.2:1), and calcined at 900°C for 2h to obtain a copper-based alloy catalyst;

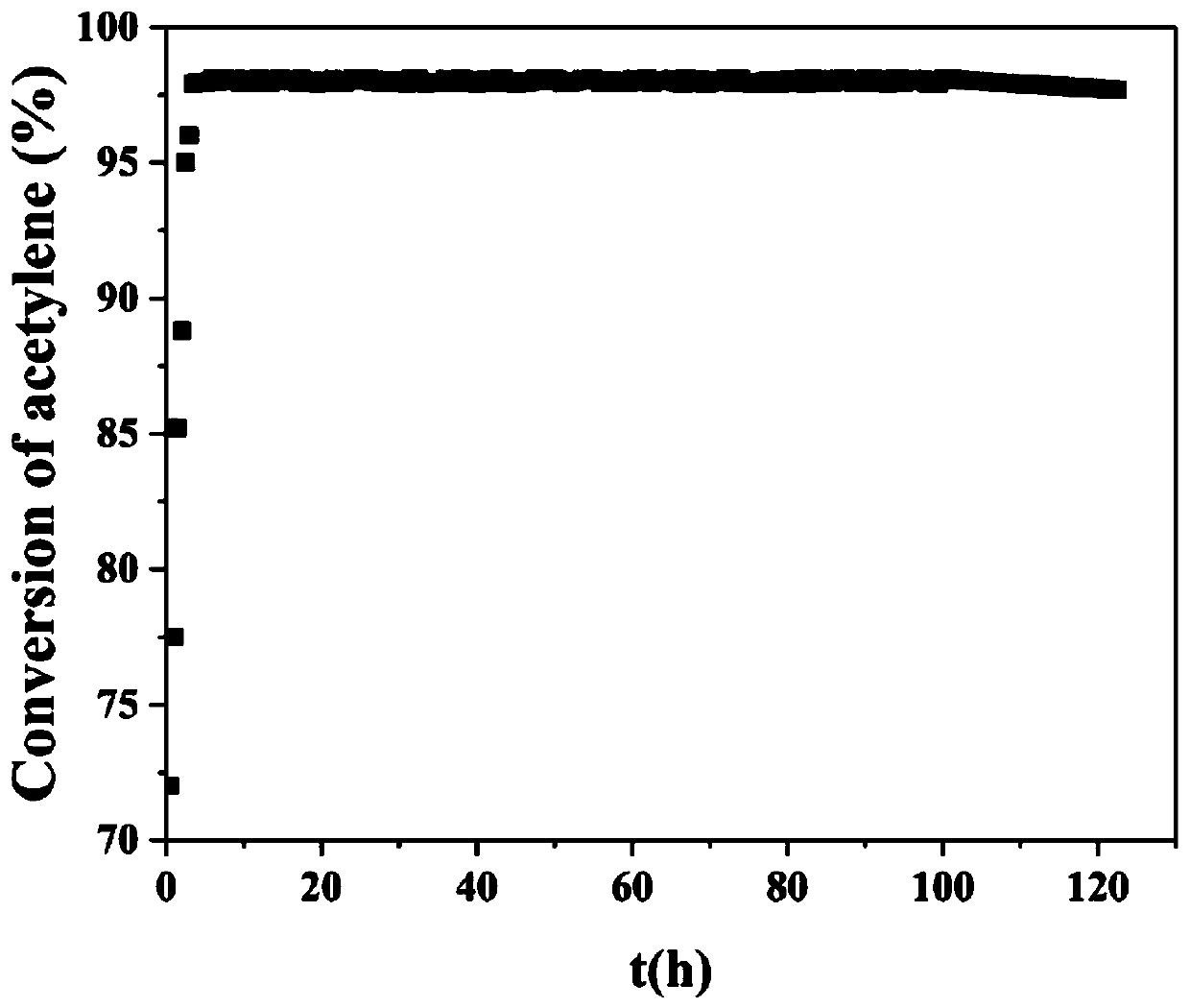

[0044] 4) the copper-based alloy catalyst of above-mentioned gained is packed on the fixed-bed reactor (HCl and C 2 h 2 The molar ratio is 1:0.95), and the volume space velocity of the reaction gas is 180h in terms of acetylene -1 , under the conditions of reaction temperature 100°C and p...

Embodiment 2

[0046] 1) Dissolve 38g of copper phosphate, 11.5g of scandium nitrate and 7.2g of tributylethylphosphine bromide in 110ml of ethanol, stir and mix evenly;

[0047] 2) Add 100g of 20 mesh γ-Al to the mixed solution in step 1) 2 o 3 , impregnated with ultrasonic (10kW) at 40°C for 1.5h, then at 150°C and 50μW / (cm 2 *nm) intensity of blue light irradiation conditions baked 5h, to obtain a completely dry catalyst;

[0048] 3) Place the catalyst obtained in step 2) in a mixed gas of ammonia and helium passing through 20ml / min (the volume flow ratio of ammonia and helium is 0.15:1), and roast at 200°C for 6h to obtain a copper-based alloy catalyst ;

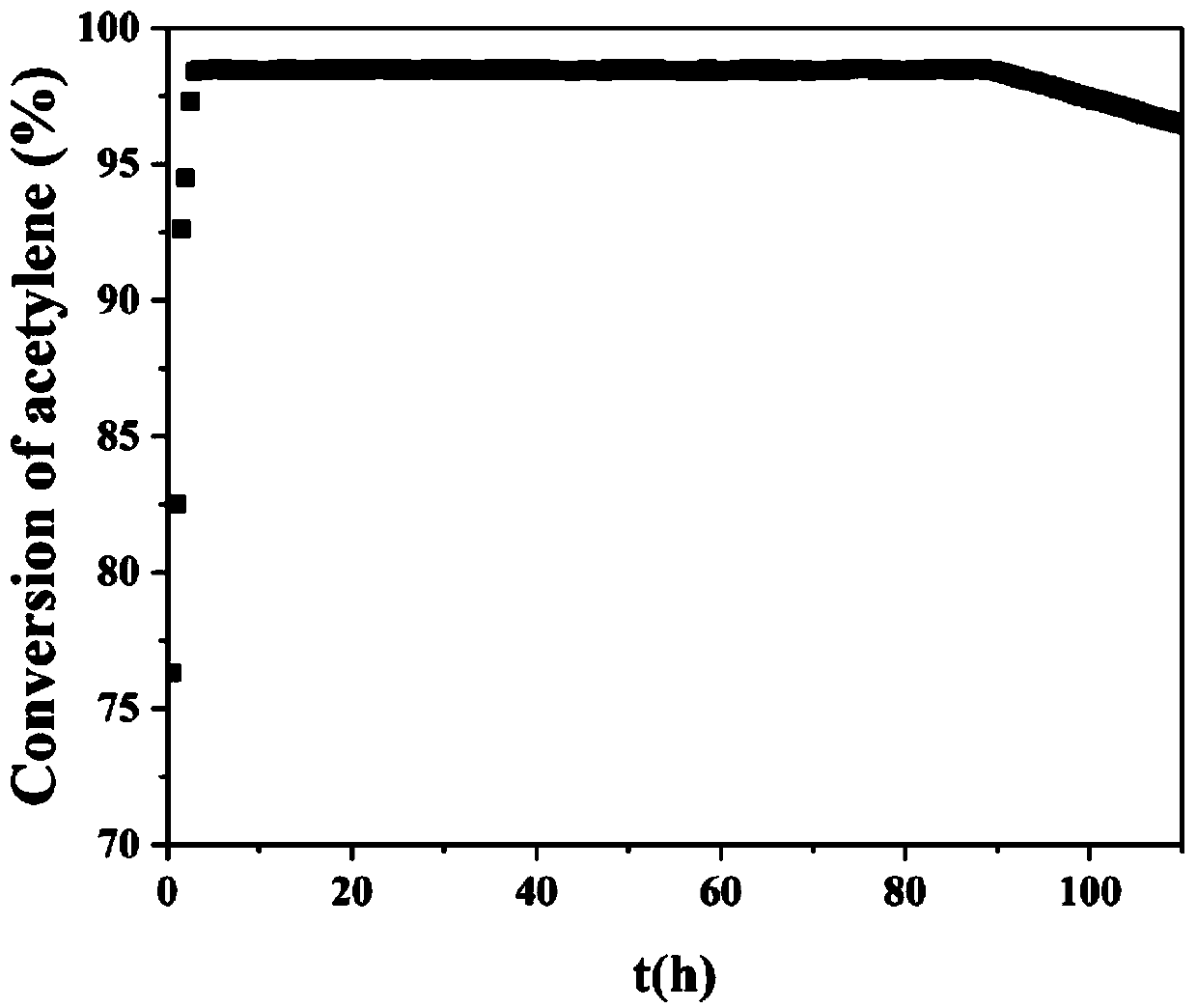

[0049] 4) the copper-based alloy catalyst of above-mentioned gained is packed on the fixed-bed reactor (HCl and C 2 h 2 The molar ratio is 1:1.1), the volume space velocity of the reaction gas is 120h in terms of acetylene -1 , the reaction temperature is 90°C, and the pressure is 0.11MPa, the acetylene hydrochlorination experime...

Embodiment 3

[0051] 1) 15.2g of copper phosphate, 27g of niobium pentachloride and 4.5g of triethylmethylammonium chloride were dissolved in 120ml of methanol water, stirred and mixed evenly;

[0052] 2) Add 100g of 20-mesh columnar titanium dioxide to the mixture in step 1), impregnate it with ultrasonic (5kW) at 60°C for 3.5h, and then 2 Bake for 8 hours under the blue light irradiation condition of *nm) intensity to obtain a completely dry catalyst;

[0053] 3) Place the catalyst obtained in step 2) in a mixed gas of methane and helium passing through 25ml / min (the volume flow ratio of methane and helium is 0.1:1), and roast at 500°C for 4h to obtain a copper-based alloy catalyst;

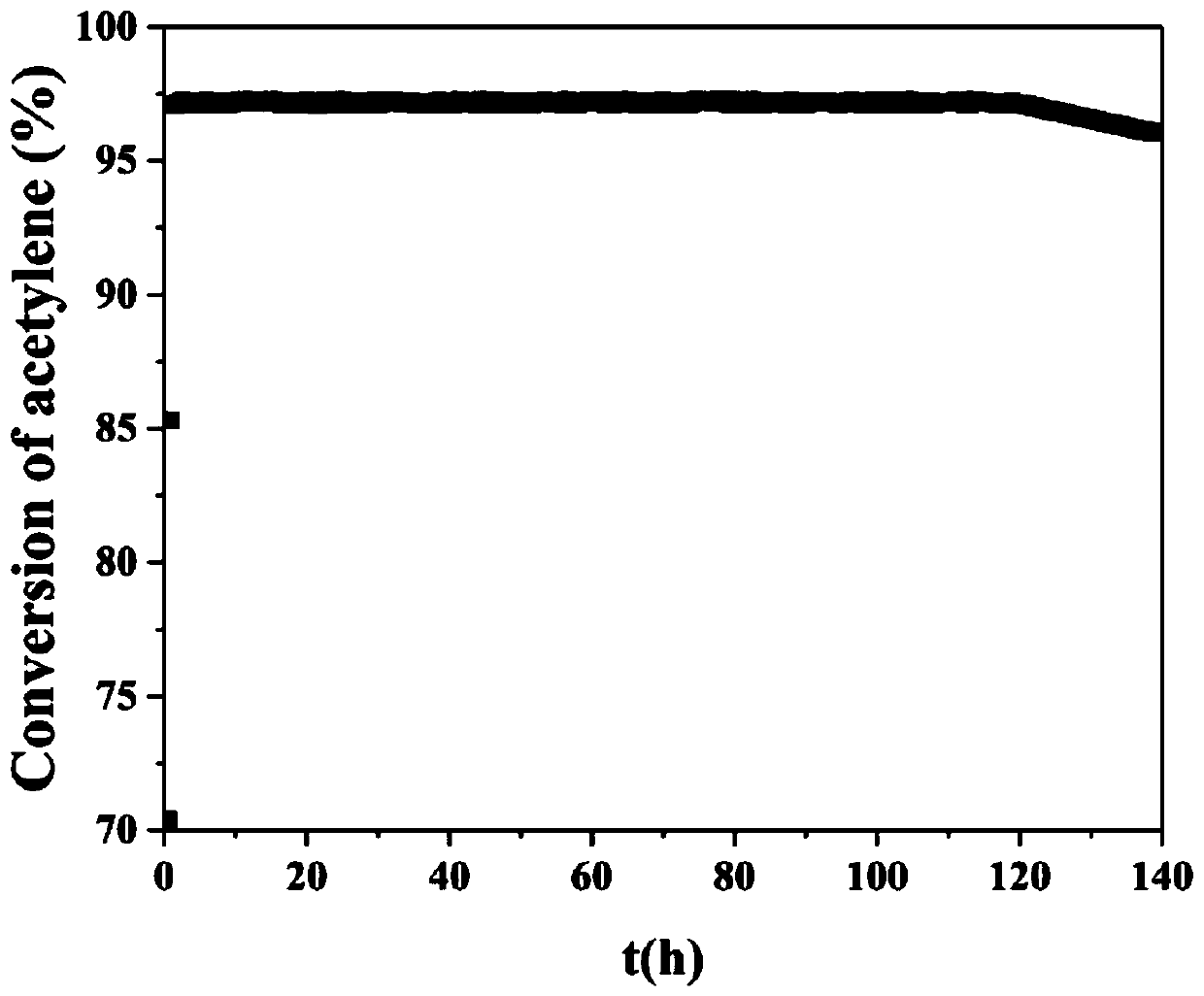

[0054] 4) the copper-based alloy catalyst of above-mentioned gained is packed on the fixed-bed reactor (HCl and C 2 h 2 The molar ratio is 1:1.05), and the volume space velocity of the reaction gas is 100h in terms of acetylene -1 , under the conditions of reaction temperature 140°C and pressure 0.1MPa, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com