Novel GaN junction barrier Schottky diode and preparation method thereof

A junction barrier Schottky and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing the difficulty and complexity of the device process, limiting the development of JBS structure devices, and high electric field strength at the edge of the positive electrode. , to achieve the effect of reducing the difficulty and complexity of the process, the effect is remarkable, and the breakdown performance is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

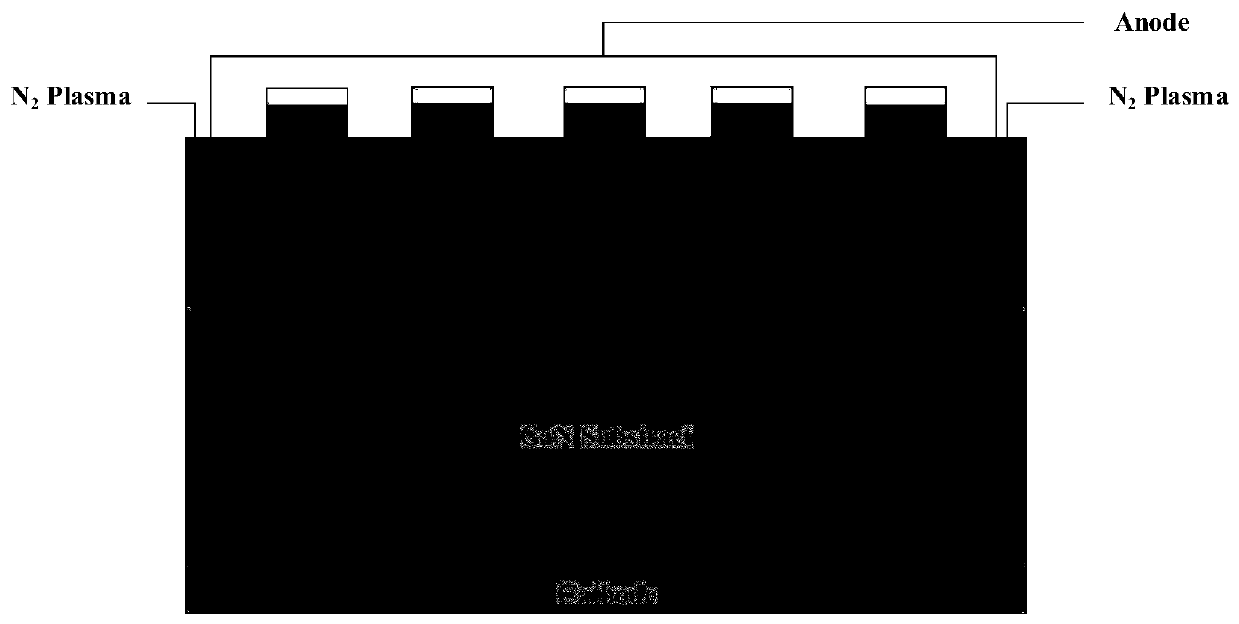

[0030] Such as figure 1 As shown, the new GaN junction barrier Schottky diode, the diode from bottom to top includes: cathode, substrate, n + type GaN epitaxial layer, n-type GaN epitaxial layer, a high resistance region formed by annular injection of plasma on the outer edge of the n-type GaN epitaxial layer, comb-shaped p-type GaN epitaxial layer, comb-shaped p + type GaN epitaxial layer and anode. The material of the substrate may be: gallium nitride, silicon and silicon carbide substrates. the n + type GaN epitaxial layer, n-type GaN epitaxial layer, comb-shaped p-type GaN epitaxial layer and comb-shaped p + The growth method of the type GaN epitaxial layer is organic chemical vapor deposition or hydride vapor phase epitaxy. In this example, the n + Type GaN epitaxial layer thickness is 2μm, carrier concentration is about 1.5x10 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com