Double metal oxide-hyperbranched polymer adsorbent and preparation method thereof

A technology of hyperbranched polymers and double metal oxides, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problem of insignificant adsorption effect, poor adsorption performance, and inability to completely adsorb heavy metals Ion and other problems, to achieve good adsorption effect, enhance the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of Ni-Fe layered double metal oxide comprises the following steps: add 200-1500mL distilled water to the reaction flask, then add nickel chloride and iron trichloride successively, the NiCl in the nickel chloride and ferric chloride 2 with FeCl 3 The molar ratio of the substance is 2.5-3.5:1, stir evenly until dissolved, then slowly add sodium hydroxide while stirring until the pH of the solution is 11-12, transfer the solution into the hydrothermal synthesis reactor, and place it in the reactor for heating Heat it in the box to 160-170°C, react for 4-8h, then place the solution in a high-speed centrifuge at a centrifugal speed of 8000-12000rpm, and perform centrifugation to remove the upper aqueous solution, wash the obtained solid mixture with an appropriate amount of distilled water, and then place Heat to 40-60°C in a blast drying oven to completely dry the water to obtain Ni-Fe layered double metal oxide.

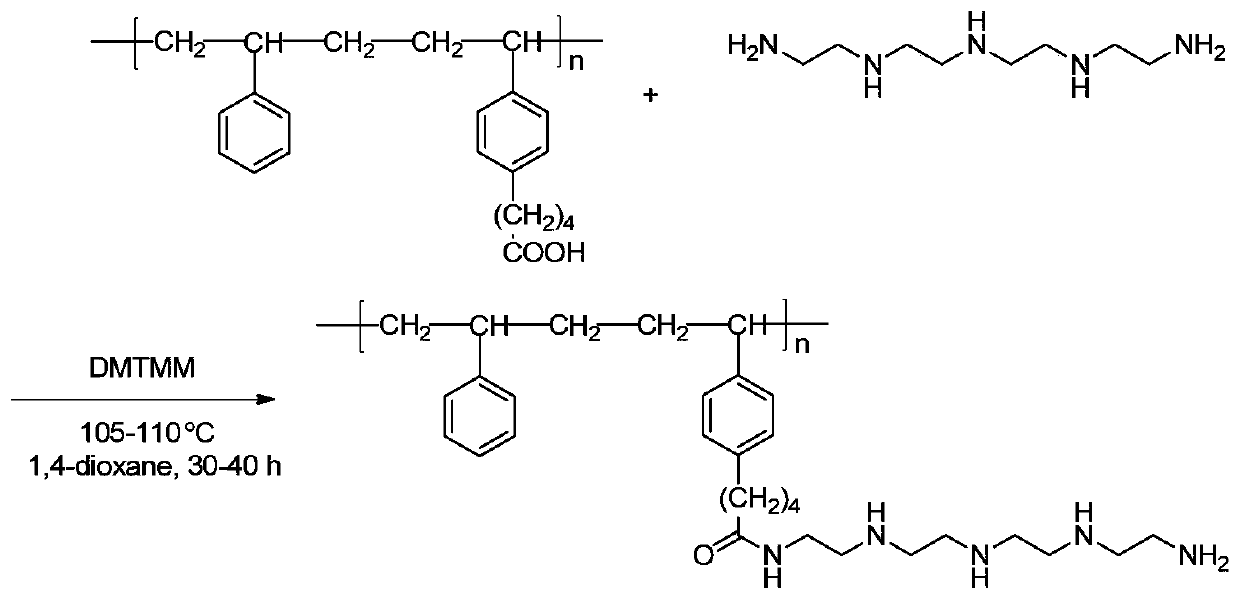

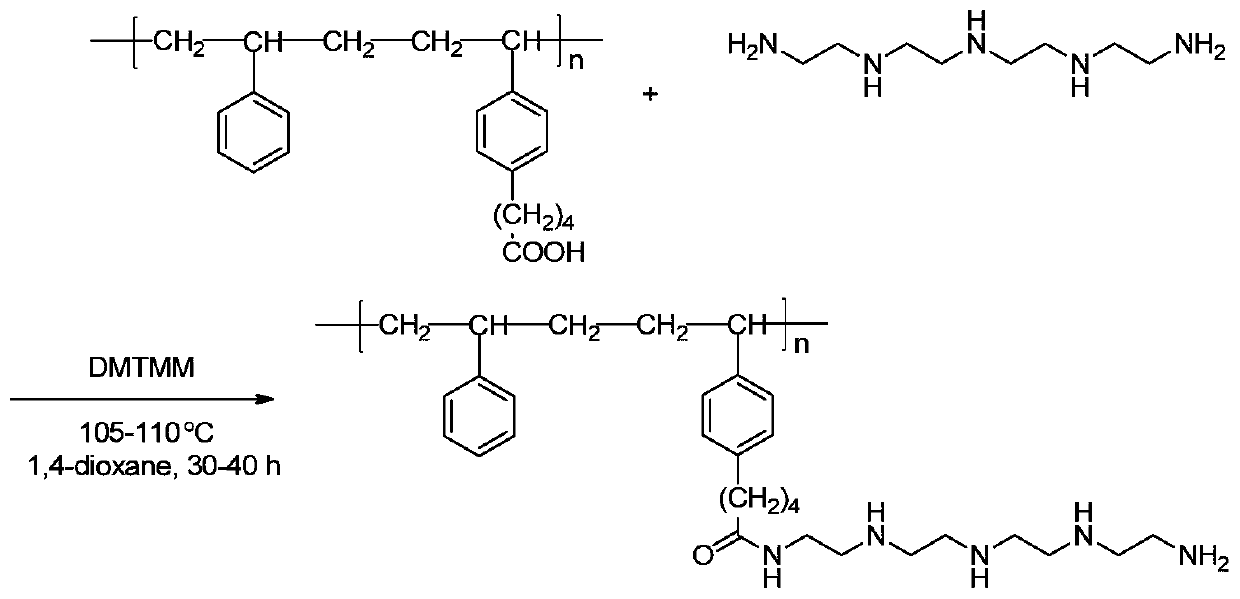

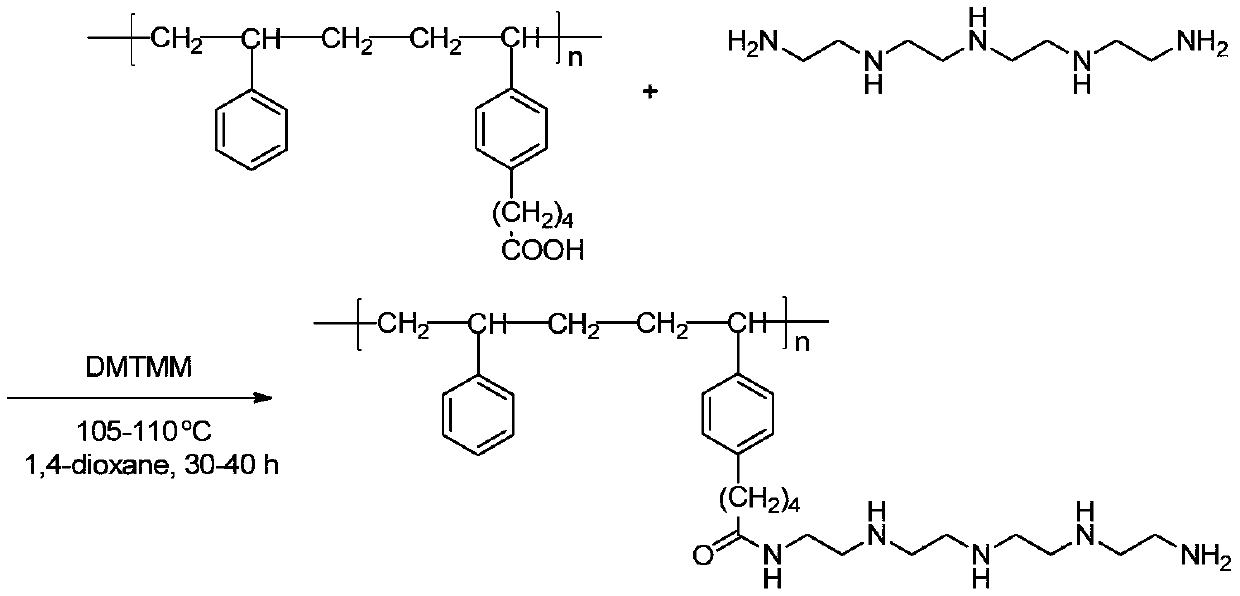

[0026] Polyethylene hyperbranched po...

Embodiment 1

[0033] (1) Preparation of Ni-Fe layered double metal oxide: add 200mL distilled water to the reaction flask, then add nickel chloride and ferric chloride successively, NiCl in the nickel chloride and ferric chloride 2 with FeCl 3 The molar ratio of the substance is 2.5:1, stir until dissolved, slowly add sodium hydroxide while stirring until the pH of the solution is 11, transfer the solution into the hydrothermal synthesis reaction kettle, and place it in the reaction kettle heating box and heat it to 160°C, react for 4 hours, then place the solution in a high-speed centrifuge at a centrifugal speed of 8000rpm, and perform centrifugation to remove the upper aqueous solution, wash the obtained solid mixture with an appropriate amount of distilled water, and then place it in a blast drying oven and heat it to 40°C Completely dry the water to obtain the Ni-Fe layered double metal oxide component 1.

[0034] (2) prepare amidated polyethylene; Carry reflux device in the three-nec...

Embodiment 2

[0039] (1) Preparation of Ni-Fe layered double metal oxide: add 500mL distilled water to the reaction flask, then add nickel chloride and ferric chloride successively, the NiCl in the nickel chloride and ferric chloride 2 with FeCl 3 The molar ratio of the substance is 2.5:1, stir until dissolved, slowly add sodium hydroxide while stirring until the pH of the solution is 11, transfer the solution into the hydrothermal synthesis reaction kettle, and place it in the reaction kettle heating box and heat it to 160°C, react for 4 hours, then place the solution in a high-speed centrifuge at a centrifugal speed of 8000rpm, and perform centrifugation to remove the upper aqueous solution, wash the obtained solid mixture with an appropriate amount of distilled water, and then place it in a blast drying oven and heat it to 40°C Completely dry the water to obtain the Ni-Fe layered double metal oxide component 2.

[0040] (2) prepare amidated polyethylene; Carry reflux device in the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com