A kind of foam cement board and preparation method thereof

A foamed cement board and cement technology, applied in the field of building materials, can solve the problems of poor mechanical properties, high brittleness, low thermal conductivity, etc., and achieve the effects of excellent thermal insulation properties, excellent mechanical properties and cohesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

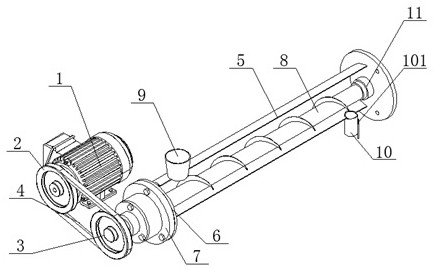

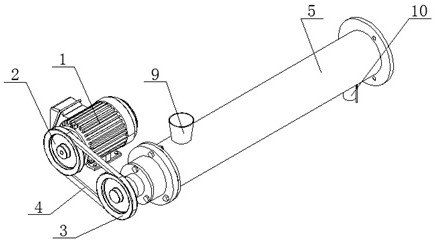

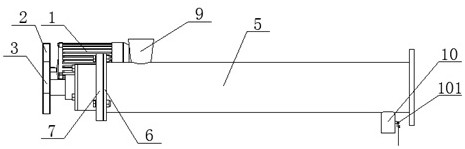

Image

Examples

Embodiment 1

[0035] Raw material composition (parts by weight): 100 parts of white Portland cement, 25 parts of polyurethane / epoxy resin / fly ash composite material, 15 parts of hydrogen peroxide, 3 parts of N-hydroxyethylethylenediaminetriacetic acid, N-phenyl -1 part of N'-cyclohexyl-p-phenylenediamine, 5 parts of cellulose ether, 3 parts of polycarboxylate superplasticizer, 5 parts of glass fiber and 50 parts of water.

[0036] The strength grade of white Portland cement is 32.5.

[0037] Polyurethane / epoxy / fly ash composites were prepared by:

[0038] S1. Composite of 20g of fly ash and 10g of epoxy resin: take fly ash and pour it into 200mL of 75% ethanol aqueous solution, add epoxy resin, stir evenly at 500r / min, process for 30min, put the compound into a dry In the oven, vacuum dry at 60°C for 1 hour;

[0039] S2. Preparation of component A: Take out 100g of the compound and add it to 20g of polyether polyol TMN450 (hydroxyl value: 220mgKOH / g), add 0.5g of dibutyltin dilaurate and ...

Embodiment 2

[0044] Composition of raw materials (parts by weight): 150 parts of composite Portland cement, 40 parts of polyurethane / epoxy resin / fly ash composite material, 20 parts of hydrogen peroxide, 7 parts of ethylenediaminetetraacetic acid, 6-ethoxy-2,2 , 3 parts of 4-trimethyl-1,2-dihydroquinoline, 10 parts of cellulose ether, 5 parts of polycarboxylate superplasticizer, 15 parts of glass fiber and 100 parts of water.

[0045] The strength grade of composite Portland cement is 32.5.

[0046] Polyurethane / epoxy / fly ash composites were prepared by:

[0047] S1. Composite of 40g of fly ash and 10g of epoxy resin: take fly ash and pour it into 200mL of 80% ethanol aqueous solution, add epoxy resin, stir evenly at 700r / min, process for 60min, put the compound into a dry In the oven, vacuum dry at 60°C for 2 hours;

[0048] S2. Preparation of component A: Take out 100g of the compound and add it to 35g of polyether polyol GR4110B (hydroxyl value: 550mgKOH / g), add 1g of N-ethylmorpholin...

Embodiment 3

[0053] Composition of raw materials (parts by weight): 125 parts of Portland cement, 32 parts of polyurethane / epoxy resin / fly ash composite material, 17 parts of hydrogen peroxide, 5 parts of diethylamine pentaacetic acid, N-phenyl-N'-isopropyl Base-2 parts of p-phenylenediamine, 7 parts of cellulose ether, 4 parts of polycarboxylate superplasticizer, 10 parts of glass fiber and 70 parts of water.

[0054] The strength grade of Portland cement is 32.5.

[0055] Polyurethane / epoxy / fly ash composites were prepared by:

[0056] S1. Compounding of 30g of fly ash and 10g of epoxy resin: take fly ash and pour it into 200mL of 77% ethanol aqueous solution, add epoxy resin, stir evenly at 600r / min, process for 45min, put the compound into a dry In the oven, vacuum dry at 60°C for 1.5h;

[0057] S2. Preparation of component A: Take out 100g of the compound and add it to 27g of polyether polyol GR4110B (hydroxyl value: 550mgKOH / g), add 0.7g of stannous isooctanoate and 0.5g of antimon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com