Thermosetting resin based on imidazole dinitrile reactive group and preparation method of thermosetting resin

A reactive group, imidazole dinitrile technology, applied in the field of thermosetting resin and its preparation, can solve the problems of inflexible molecular design and structure modification, hindering the composite modification of phthalonitrile and other resins, and achieve excellent structure The effects of modifiability, low cost, and wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In this embodiment, the imidazole dinitrile single-molecule resin (4,5-dicyanoimidazole, DCI, purchased from the market) and the curing agent (3,3'-(1,3-phenylene bis(oxy))diphenylamine , m-APB) is that raw material is prepared according to the following steps:

[0064] (1) 10 g of DCI and 0.8 g of m-APB were dissolved in 200 mL of tetrahydrofuran and mixed uniformly, and then the resulting mixture was spin-dried and ground to obtain a blended powder.

[0065] (2) The obtained blended powder is solidified in accordance with the following temperature gradients in a nitrogen atmosphere: heat preservation at 150°C for 1 hour, heat preservation at 210°C for 10 hours, heat preservation at 290°C for 1 hour, and cool to room temperature with the furnace after curing, that is A thermosetting resin is obtained.

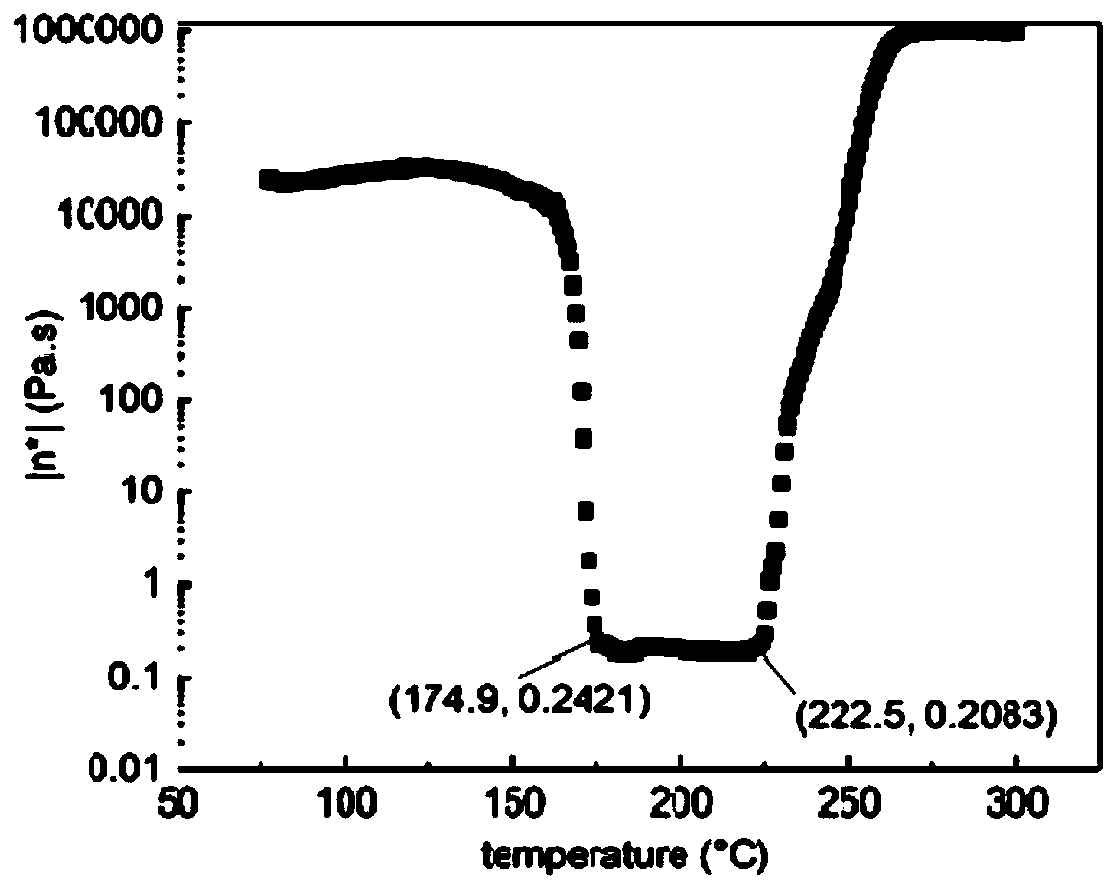

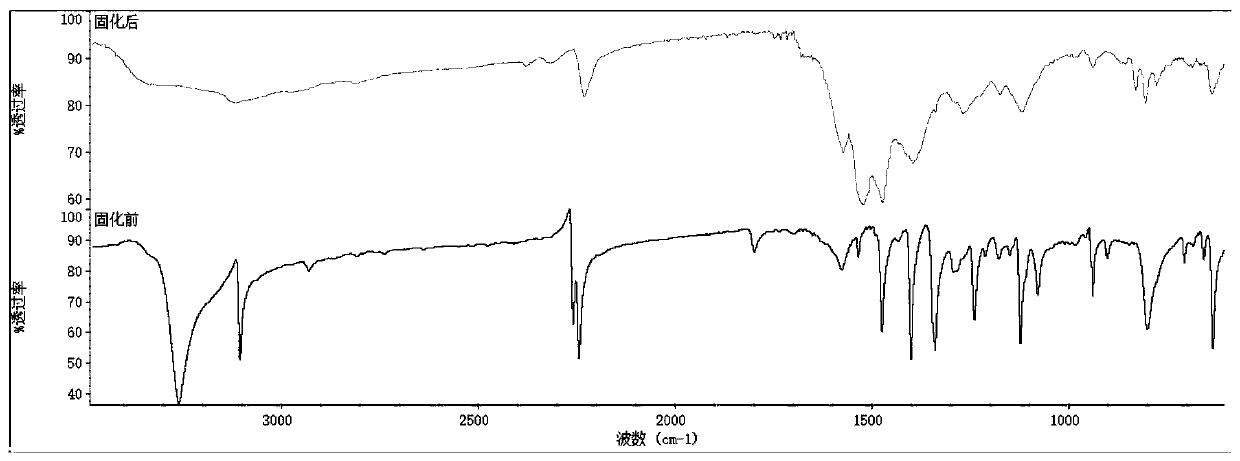

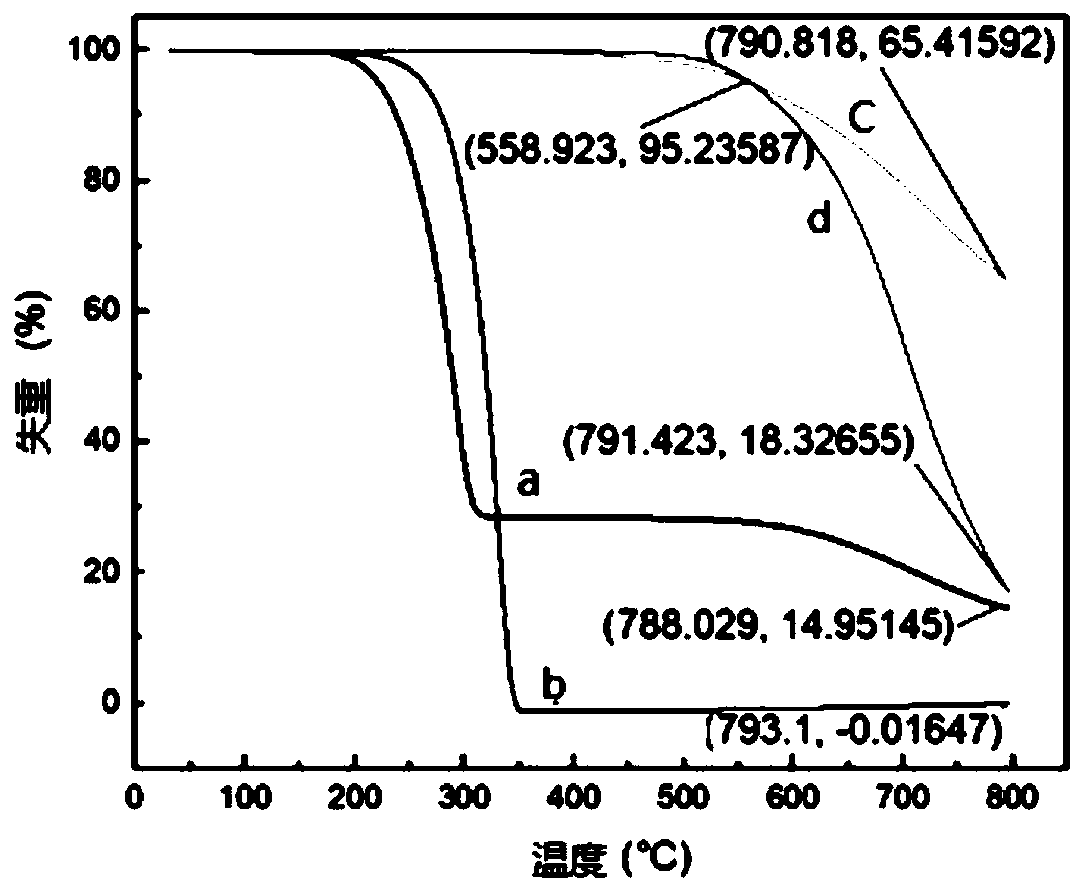

[0066] The blended powder that step (1) obtains adopts rheometer to carry out rheological test, obtains the rheological curve that viscosity changes with temperature, ...

Embodiment 2

[0070] In this embodiment, the imidazole dinitrile monomolecular resin (2,2', 2"-((benzene-1,3,5-triyltri(oxygen))tri(benzene-4,1-diyl))tri( 1H-imidazole-4,5-dinitrile)) and curing agent ZnCl 2 Prepared as raw material according to the following steps:

[0071] (1) Add phloroglucinol (10mmol), potassium carbonate (45mmol) and dry DMF (dimethylformamide, 30mL) into the container, then raise the temperature to 80°C under stirring, and The reaction was carried out for 1 h, and then lowered to room temperature, then 4-fluorobenzaldehyde (40 mmol) was added to the container, and the temperature was raised to reflux, and after 20 h of reflux, the temperature was cooled to room temperature, and the resulting reaction solution was poured into a 500 mL ice-water bath for precipitation, and then Use hydrochloric acid to adjust the pH of the mixed solution containing the precipitate to neutral, filter and collect the filter cake, wash with deionized water and filter three times (100 mL ...

Embodiment 3

[0077] In this example, the imidazole dinitrile monomolecular resin (1,1', 1"-((benzene-1,3,5-triyltri(oxygen))tri(3-(trifluoromethyl)benzene-4, 1-diyl)) tris(1H-imidazole-4,5-dicarbonitrile)) and curing agent (2,2'-(oxybis(4,1-phenylene))bis(3α,4,7 ,7a Tetrahydro-1H-isoindole-1,3(2H)-dione)) (for preparation method see Yuan P, Ji S, Hu J, etal.Systematic study on highly efficient thermal synergistic polymerization effect between alicyclic imide moiety and phthalonitrile: scope, properties and mechanism [J]. Polymer, 2016, 102: 266-280) is prepared as raw material according to the following steps:

[0078] (1) Add DCI (15mmol), potassium carbonate (45mmol) and dry DMSO (dimethyl sulfoxide, 60mL) into the container, then react at room temperature for 1h under stirring conditions, and then add 2- Trifluoromethyl-5-fluoronitrobenzene (15mmol), and heated to 80 ° C for 24h, then cooled to room temperature, the resulting reaction solution was poured into a 500mL ice-water bath for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com