Preparation method and application of nitrogen-phosphorus double-doped graded porous carbon material

A hierarchical porous, double-doped technology, applied in the direction of active material electrodes, electrical components, battery electrodes, etc., can solve the problems of complex process and difficult control, and achieve the effect of low price, simple operation and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

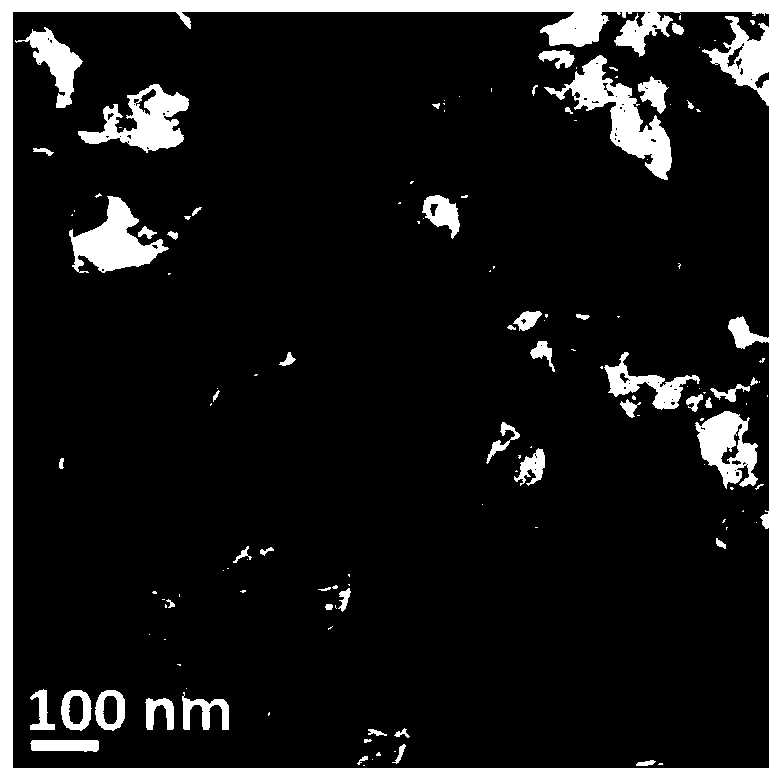

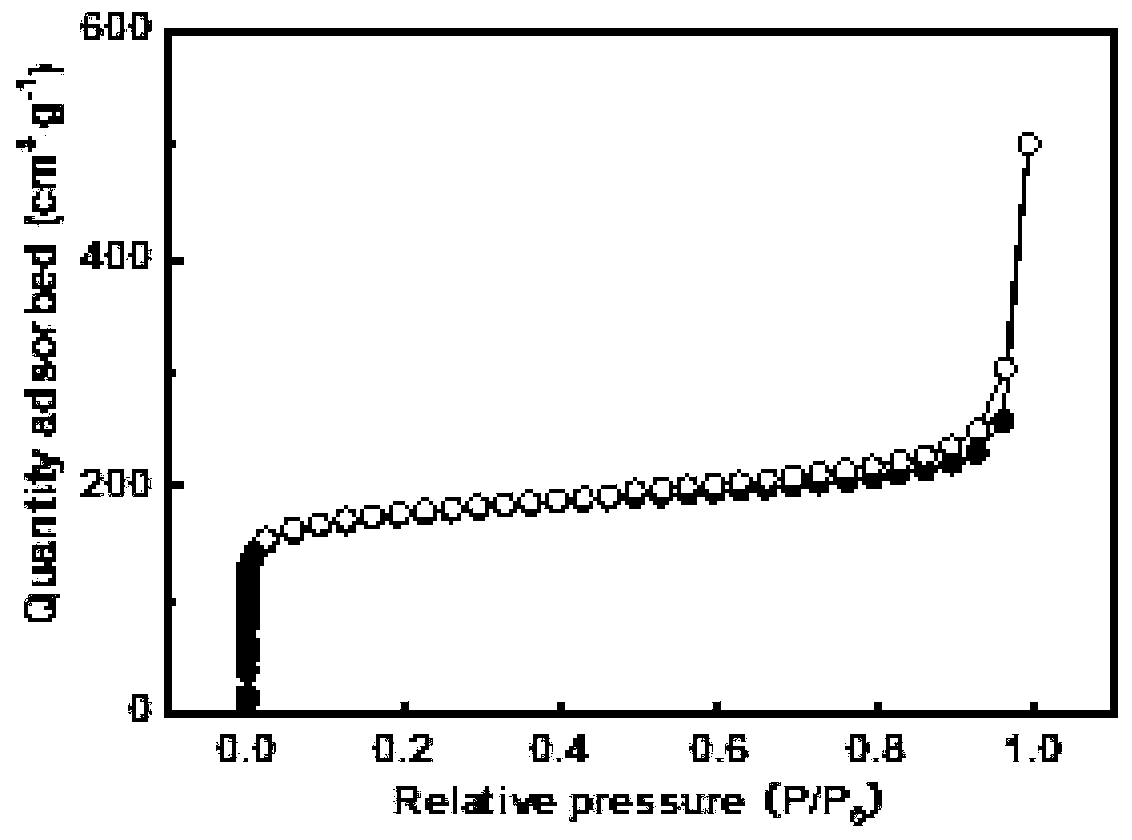

[0041] Embodiment 1: In this embodiment, the preparation method of nitrogen-phosphorus double-doped hierarchical porous carbon material is carried out according to the following steps:

[0042] Step 1. Dissolve 4.85mL aniline in 20mL with a concentration of 0.1mol L -1 In the phytic acid aqueous solution, stir and mix evenly;

[0043] Step 2, then add 10mL concentration of 2.5mol L -1 Aqueous ammonium persulfate solution, mixed evenly, left to react at 5°C for 12 hours, after the reaction, washed with water, and freeze-dried at -50°C for 36 hours to obtain polyaniline phytic acid airgel;

[0044] Step 3. Ultrasonic disperse 1 g of the polyaniline phytic acid airgel obtained in Step 2 in 100 g of NaCl aqueous solution with a mass fraction of 10%, and heat and evaporate to dryness at 80° C.;

[0045] Step 4, then carbonize in a nitrogen atmosphere at 900°C for 2h, treat with 10wt% sulfuric acid to remove soluble matter, wash with water, and vacuum dry at 100°C for 24h to obtai...

Embodiment 2

[0051] Embodiment 2: In this embodiment, the preparation method of nitrogen-phosphorus double-doped hierarchical porous carbon material is carried out according to the following steps:

[0052] Step 1. Dissolve 4.85mL aniline in 20mL with a concentration of 0.1mol L -1 In the phytic acid aqueous solution, stir and mix evenly;

[0053] Step 2, then add 10mL concentration of 2.5mol L -1 Aqueous ammonium persulfate solution, mixed evenly, left to react at 5°C for 12 hours, after the reaction, washed with water, and freeze-dried at -50°C for 36 hours to obtain polyaniline phytic acid airgel;

[0054] Step 3. Ultrasonic disperse 1 g of the polyaniline phytic acid airgel obtained in Step 2 in 100 g of LiCl aqueous solution with a mass fraction of 10%, and heat and evaporate to dryness at 80° C.;

[0055] Step 4, then carbonize in a nitrogen atmosphere at 700°C for 2h, treat with 10wt% sulfuric acid to remove soluble matter, wash with water, and vacuum dry at 100°C for 24h to obtai...

Embodiment 3

[0056] Embodiment 3: In this embodiment, the preparation method of nitrogen-phosphorus double-doped hierarchical porous carbon material is carried out according to the following steps:

[0057] Step 1. Dissolve 4.85mL aniline in 20mL with a concentration of 0.1mol L -1 In the phytic acid aqueous solution, stir and mix evenly;

[0058] Step 2, then add 10mL concentration of 2.5mol L -1 Aqueous ammonium persulfate solution, mixed evenly, left to react at 5°C for 12 hours, after the reaction, washed with water, and freeze-dried at -50°C for 36 hours to obtain polyaniline phytic acid airgel;

[0059] Step 3. Ultrasonic disperse 1 g of the polyaniline phytic acid airgel obtained in Step 2 in 100 g of 10% KCl aqueous solution by mass fraction, and heat and evaporate to dryness at 80° C.;

[0060] Step 4, then carbonize in nitrogen atmosphere at 800°C for 2h, treat with 10wt% sulfuric acid to remove soluble matter, wash with water, and vacuum dry at 100°C for 24h to obtain nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com