Environment-friendly and degradable thermal insulation food packaging bag

A packaging bag and food technology, applied in the field of new materials, can solve the problems of weakened heat insulation effect of packaging bags and peeling off of heat insulation coating, and achieve excellent heat insulation effect, avoid softening deformation, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

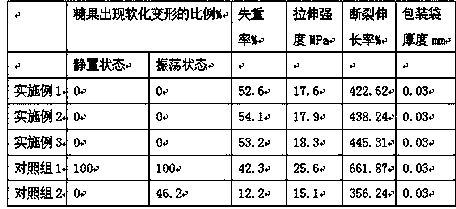

Examples

Embodiment 1

[0023] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0024] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 800r / min for 2h, then add trimethylchlorosilane and February Dibutyltin silicate, under the condition of 30°C, stirred and reacted at a speed of 150r / min for 3h, and then stood still for 40h to obtain a modified silica sol;

[0025] 2) Mix butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances and stir evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 700r / min for 2h, Then add it to the modified silica sol, stir for 3 hours at a rotating speed of 150r / min, and let it stand for 40 hours to obtain a composite sol;

[0026]3) Pour the composite sol into a high-pressure spray gun, s...

Embodiment 2

[0036] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0037] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 900r / min for 1.5h, then add trimethylchlorosilane and dichlorosilane Dibutyltin lauricate was stirred and reacted at a speed of 180r / min for 2.5h at 35°C, and then left to stand for 45h to obtain a modified silica sol;

[0038] 2) Mix butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances and stir evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 800r / min for 1.5h , then added to the modified silica sol, stirred for 2.5 hours at a rotational speed of 200r / min, and left to stand for 42 hours to obtain a composite sol;

[0039] 3) Pour the composite sol into a high-pressure spray ...

Embodiment 3

[0049] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0050] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 1100r / min for 1h, then add trimethylchlorosilane and February Dibutyltin silicate, under the condition of 40°C, stirred and reacted at a speed of 200r / min for 2h, and then stood still for 50h to obtain a modified silica sol;

[0051] 2) Mix and stir butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 1000r / min for 1h, Then add it to the modified silica sol, stir for 2 hours at a rotating speed of 250r / min, and let it stand for 45 hours to obtain a composite sol;

[0052] 3) Pour the composite sol into a high-pressure spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com