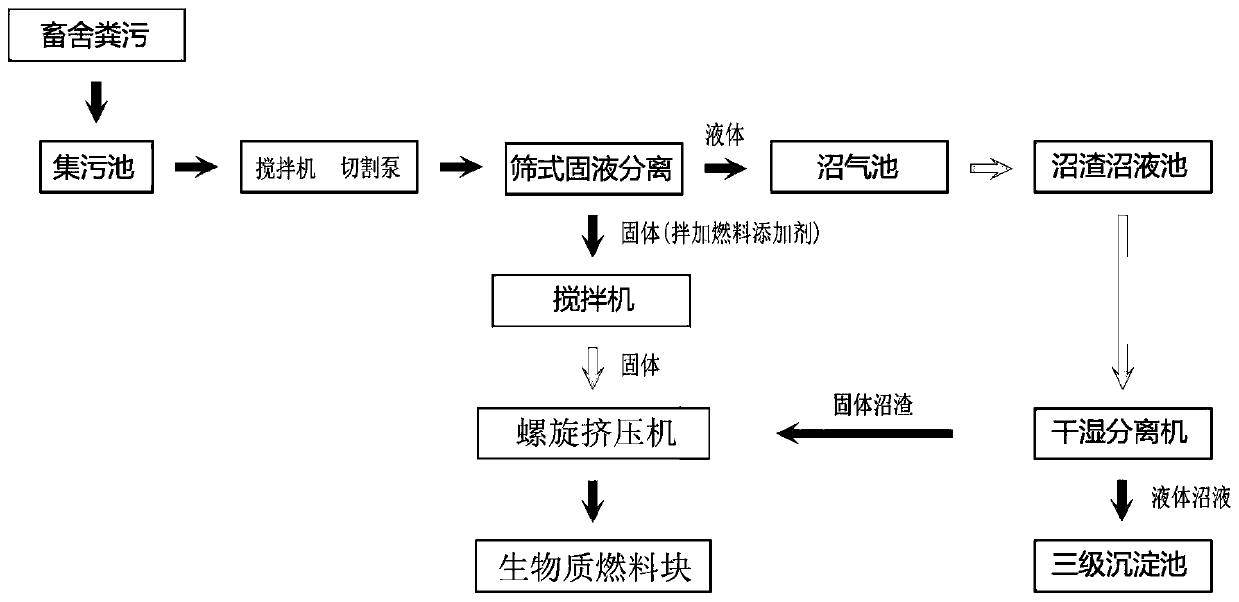

Method for preparing biomass molding fuel by pressing pig manure

A technology for forming fuel and pig manure, which is applied in the fields of biofuel, waste fuel, fuel, etc., can solve the problems of extremely high moisture content of pig manure, high energy consumption of equipment investment, and difficulty in grasping the moisture content of pig manure, so as to save electricity. The effect of investment, saving equipment investment, and convenient storage and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

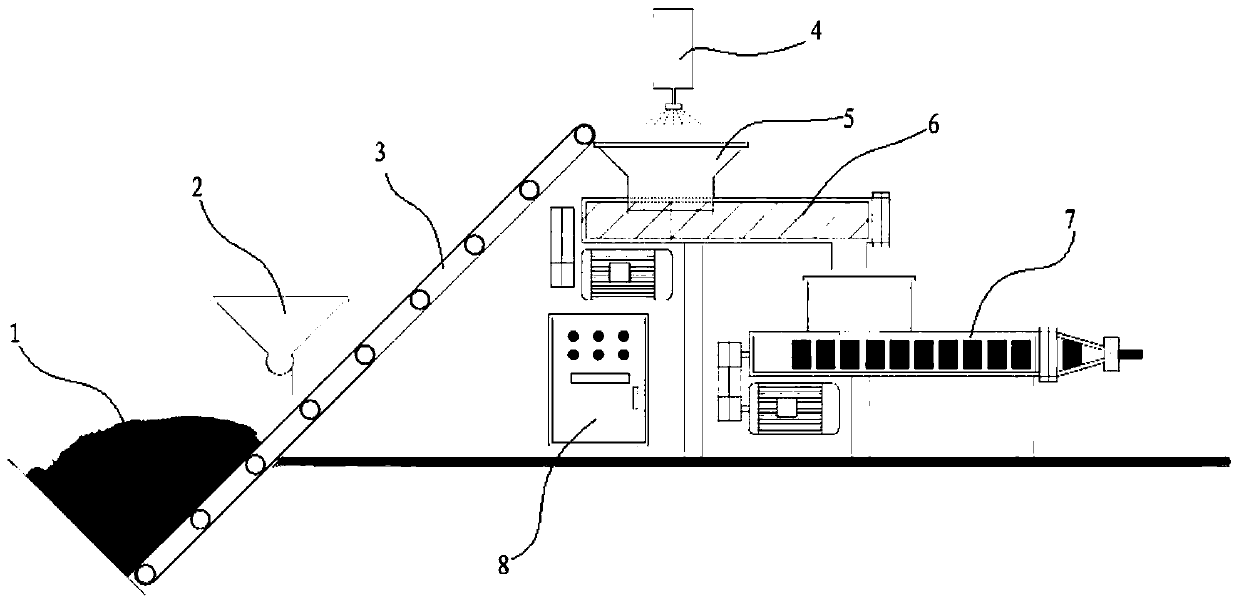

[0044] Example 1: With reference to the accompanying drawings, which reflects a specific structure of the present invention, the preparation system of the compressed biomass fuel from pig manure consists of an upper silo 1, an auxiliary material addition silo 2, and its lowering auger and conveyor belt 3. Bacteria sprayer 4, mixer 6, screw extrusion molding machine 7 (such as 140 coal stick machine), block cutter and control box system 8 constitute a continuous production line, and the loading bin 1 is connected by a conveyor belt 3. The feed port 5 of the mixer 6, the conveyor belt 2 between the loading bin 1 and the mixer 6 is connected to the auxiliary material adding bin 2 through the feed auger. The feed port 5 of the mixer 6 is equipped with a bacterial seed liquid sprayer 4 and a mixer 6 The discharge port is connected to the feed port of the screw extrusion molding machine 7, and the discharge port of the screw extrusion molding machine 7 is provided with a block cutter ...

Embodiment 2

[0059] Embodiment 2: The difference from embodiment 1 is:

[0060] ① In the preparation stage, take the dried pig manure that has been fermented in the organic fertilizer fermentation bed of the pig farm, with a moisture content of 21%;

[0061] The proportion is: 78 parts of pig manure residue, 15 parts of coal powder, 1.5 parts of sodium carboxymethyl starch, 2 parts of potassium chlorate, 2 parts of decoking agent, 0.5 parts of anti-smoke agent, 4 parts of industrial salt, pig manure fermentation biological bacteria Species (aqueous) 1 part.

[0062] The moisture content of the pretreated mixture is 20%.

[0063] ②The moisture content of the molded body is 20%.

[0064] ③The moisture content of the finished biomass fuel block is 14%. The total sharing time is 1 day.

[0065] The biomass fuel block produced in this embodiment is a hexagonal hollow column with a diameter of 38 mm, a hollow diameter of 12 mm, and a length of 5 cm. The density is 1290kg / m 3 . No smell. It burns fully...

Embodiment 3

[0066] Embodiment 3: The difference from embodiment 1 is:

[0067] ①Dry manure removal method in the preparation stage collects fresh pig manure residue in the pig farm with a moisture content of 65%;

[0068] The proportion is: 75 parts of pig manure residue, 13 parts of coal powder, 1 part of sodium carboxymethyl starch, 3 parts of potassium chlorate, 2 parts of decoking agent, 1 part of anti-smoke agent, 6 parts of industrial salt, pig manure fermentation biological bacteria Species 1 copy.

[0069] The moisture content of the pretreated mixture is 58%.

[0070] ②The moisture content of the molded body is 58%.

[0071] ③The room temperature in the insulation room is 28℃. The maximum temperature of the fuel block reached 70°C after being placed in the fuel block for 34 hours. The moisture content of the finished biomass fuel block is 16%. The total sharing time is 4 days.

[0072] The biomass fuel block produced in this embodiment is a hexagonal hollow cylinder with a diameter of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hollow diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com