Environment-friendly catalyst for preparing propylene by directly dehydrogenating propane and preparation method thereof

An environmentally friendly, catalyst technology, applied in the direction of catalyst, molecular sieve catalyst, carbon compound catalyst, etc., can solve the problem of uncoordinated conversion rate and selectivity of dehydrogenation catalyst, difficult fluidized bed reactor application, low propane volume space velocity, etc. problems, to achieve good industrial application prospects, high propylene selectivity, high temperature thermal stability and good strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

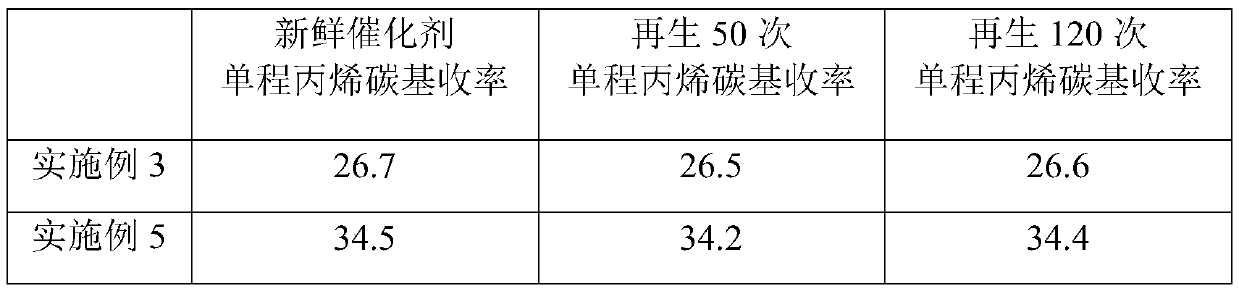

Examples

Embodiment 1

[0048] 1) Weigh 100g of Hβ molecular sieve and measured zinc nitrate into a container, add (total mass of Hβ molecular sieve and zinc nitrate) about 10 times the mass of deionized water, seal and stir at 90°C for 6 hours, then open the cover stirring and evaporating to dryness, and then calcining at 500°C for 4 hours in a calciner to obtain Zn-doped modified Hβ molecular sieves for use;

[0049] 2) After mixing the weighed ammonium metatungstate, cobalt nitrate, nickel nitrate, lanthanum nitrate, phosphoric acid and sodium nitrate, add the measured 1mol / L oxalic acid aqueous solution and stir to dissolve at 70°C, wherein the oxalic acid solution is mixed with the modified The total weight ratio of active agent is 2.0ml / g.

[0050] 3) Mix the Zn-doped Hβ molecular sieve obtained in step 1) with the measured macroporous pseudo-boehmite, and then add 2.0 times the total weight of the solid powder in deionized water and the modifier solution prepared in step 2), Stir and mix even...

Embodiment 2

[0054] 1) Weigh 200g of Hβ molecular sieve and measured zinc nitrate into a container, add about 10 times the mass of deionized water, seal it and stir at 60°C for 24 hours, then open the cover, stir and evaporate to dryness, and then put it in a calciner at Calcined at 600°C for 2 hours to obtain Zn-doped modified Hβ molecular sieve;

[0055] 2) After mixing the weighed ammonium molybdate, manganese nitrate, zirconium nitrate, indium nitrate, cerium nitrate and strontium nitrate, add the measured 1mol / L oxalic acid aqueous solution and stir to dissolve at 90°C, wherein the volume of the oxalic acid solution is equal to Modifier total weight ratio 1.5ml / g.

[0056] 3) Mix the Zn-doped Hβ molecular sieve obtained in step 1) with the measured macroporous pseudo-boehmite, then add 3.0 times the total weight of the solid powder in deionized water and the modifier solution prepared in step 2), Stir and mix evenly; then gradually add nitric acid solution dropwise under stirring to ...

Embodiment 3

[0060] 1) Weigh 100g of Hβ molecular sieve and measured zinc nitrate into a container, add about 10 times the mass of deionized water, seal it and stir at 90°C for 4 hours, then open the lid, stir and evaporate to dryness, then put it in a calciner at Calcined at 400°C for 8 hours to obtain Zn-doped modified Hβ molecular sieve;

[0061] 2) After mixing the weighed ammonium molybdate, nickel nitrate, gallium nitrate, indium nitrate and sodium nitrate, add a measured 1mol / L citric acid aqueous solution and stir to dissolve at 50°C, wherein the volume of the oxalic acid solution is the same as that of the modified The total weight ratio of the agent is 1.8ml / g.

[0062] 3) Mix the Zn-doped Hβ molecular sieve obtained in step 1) with the measured large-pore pseudo-boehmite, then add 3.5 times the total weight of the solid powder in deionized water and the modifier solution prepared in step 2), Stir and mix evenly; then gradually add nitric acid solution dropwise under stirring to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com