Hydrophobic enhanced calligraphy and painting paper and making method thereof

A kind of painting and calligraphy paper, enhanced technology, applied in the field of papermaking, to achieve the effect of not easy to absorb moisture and mildew, enhance the water vapor barrier performance, and prolong the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

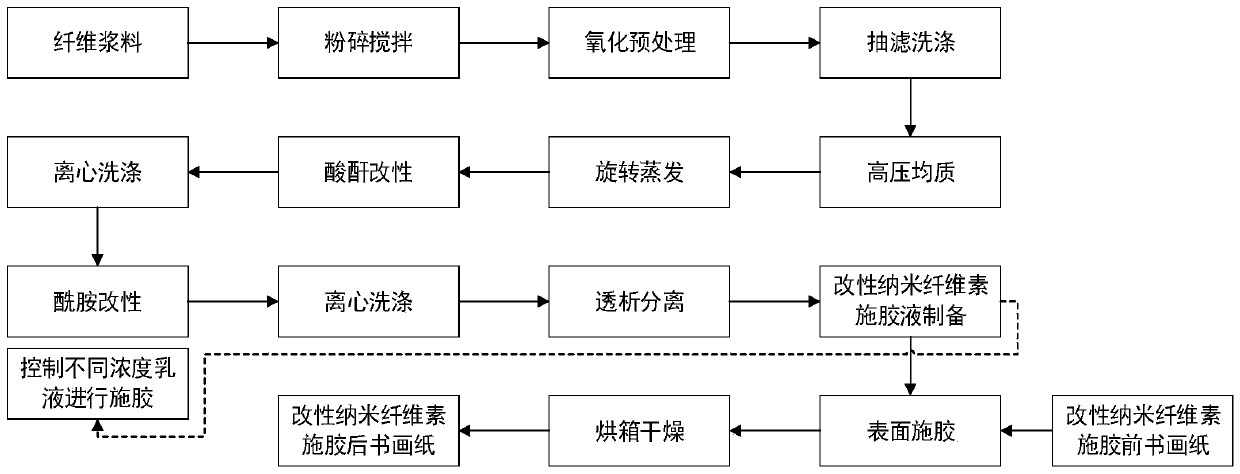

Method used

Image

Examples

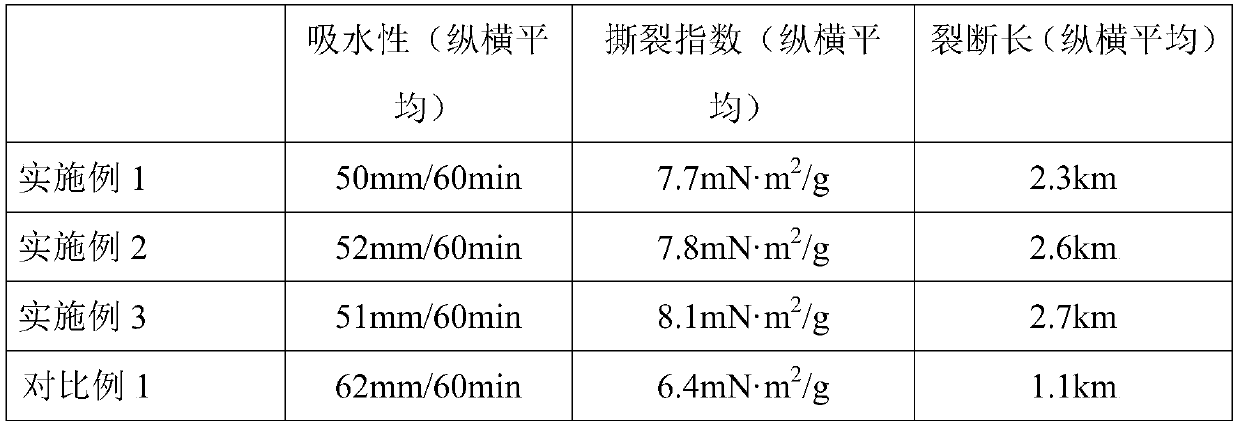

Embodiment 1

[0047] A kind of preparation method of hydrophobic enhanced type calligraphy and painting paper of the present embodiment, described method specific steps are as follows:

[0048] (1) Preparation of oxidized cellulose

[0049] Use 0.1mol / L sodium carbonate solution and 0.1mol / L sodium bicarbonate solution in a volume ratio of 3:2 to prepare 400mL of pH=10 buffer solution, take 300mL in a 500mL three-necked flask; weigh 5g of Dry hardwood pulp, crush the pulp with a pulverizer, then add it to the above flask, and stir it fully with a magnetic stirrer; then weigh 2,2,6,6-tetramethylpiperidine oxide and bromide in sequence Sodium, join in the described flask, after fully dissolving, then measure the sodium hypochlorite solution of the concentration 30% of 35ml and join in the flask, start reaction at room temperature after mixing, use the hydrogen of 0.1mol / L during the reaction The sodium oxide solution adjusts the pH of the reaction solution to about 10; the total reaction tim...

Embodiment 2

[0058] A kind of preparation method of hydrophobic enhanced type calligraphy and painting paper of the present embodiment, described method specific steps are as follows:

[0059] (1) Preparation of oxidized cellulose

[0060] Use 0.1mol / L sodium carbonate solution and 0.1mol / L sodium bicarbonate solution at a volume ratio of 1:0.5 to prepare 400mL of pH=9.5 buffer solution, take 300mL in a 500mL three-necked flask; weigh 5g of Dry hardwood pulp, crush the pulp with a pulverizer, then add it to the above flask, and stir it fully with a magnetic stirrer; then weigh 2,2,6,6-tetramethylpiperidine oxide and bromide in sequence Sodium, join in the described flask, after being fully dissolved, measure the sodium hypochlorite solution of the concentration 30% of 50ml again and join in the flask, start reaction at room temperature after mixing, use the hydrogen of 0.1mol / L during the reaction The sodium oxide solution adjusts the pH of the reaction solution to about 9.5; the total re...

Embodiment 3

[0069] A kind of preparation method of hydrophobic enhanced type calligraphy and painting paper of the present embodiment, described method specific steps are as follows:

[0070] (1) Preparation of oxidized cellulose

[0071] Use 0.1mol / L sodium carbonate solution and 0.1mol / L sodium bicarbonate solution to prepare 400mL buffer solution with pH=9 at a volume ratio of 1:1, take 300mL in a 500mL three-necked flask; weigh 5g of Dry hardwood pulp, crush the pulp with a pulverizer, then add it to the above flask, and stir it fully with a magnetic stirrer; then weigh 2,2,6,6-tetramethylpiperidine oxide and bromide in sequence Sodium, join in the described flask, after being fully dissolved, measure the sodium hypochlorite solution of the concentration 30% of 60ml again and join in the flask, start reaction under room temperature condition after mixing, use the hydrogen of 0.1mol / L during the reaction The sodium oxide solution adjusts the pH of the reaction solution to about 9; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com