A composite metal oxide desulfurization and dearsenic agent and its preparation method

A technology for desulfurization, arsenic removal, and composite metals, which is applied in the fields of refining metal oxides, chemical instruments and methods, and other chemical processes. It can solve problems such as high production costs, high energy consumption, and complicated preparation processes, and achieve low production costs. , low energy consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

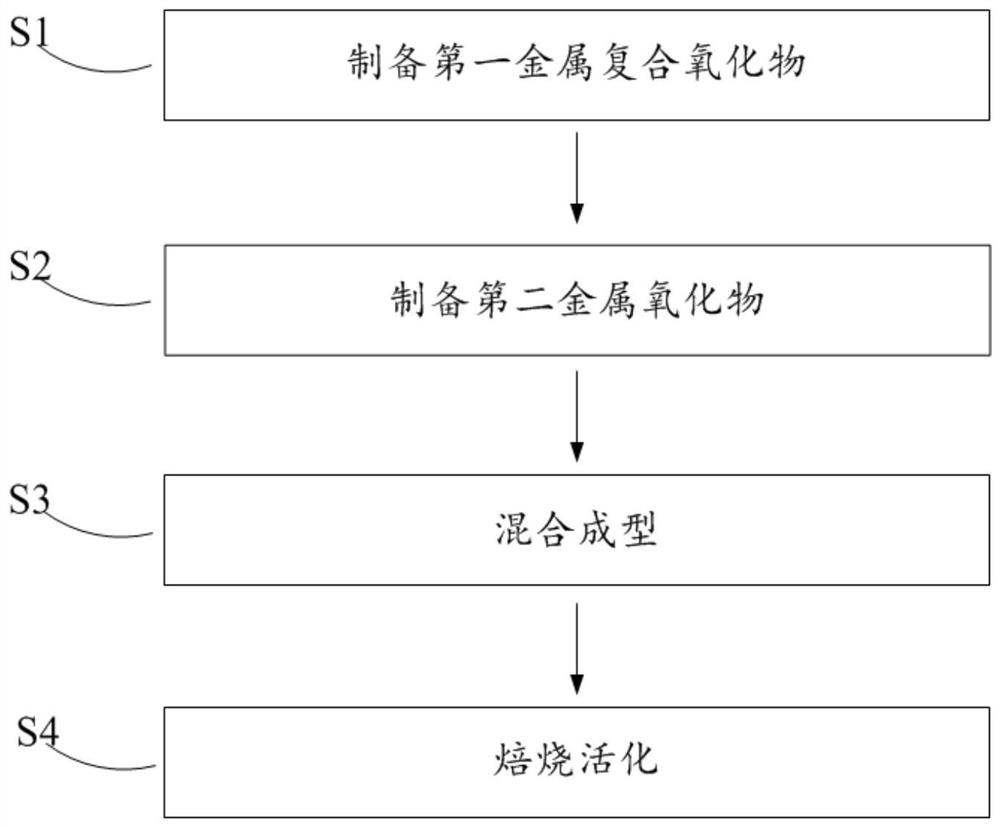

[0025] For the second solution of the present invention, the present invention proposes a kind of preparation method of composite metal oxide desulfurization and dearsenic agent, such as figure 1 , including the following steps:

[0026] S1: preparing the first metal composite oxide; S2: preparing the second metal oxide; S3: mixed molding; S4: roasting activation;

[0027] The method for preparing the composite metal oxide desulfurization and arsenic removal agent provided in the above second solution is used to prepare the composite metal oxide desulfurization and arsenic removal agent provided in the first solution of the present invention.

[0028] In the present invention, the reasons for separately preparing the first metal composite oxide and the second metal oxide are as follows:

[0029] (1) The precipitation environments of the first metal ion and the second metal ion are different, resulting in inconsistent precipitation sequences of the first metal ion and the seco...

Embodiment 1

[0043] This embodiment provides a composite metal oxide desulfurization and arsenic removal agent, obtained through the following steps:

[0044] S1: Weigh the calculated amounts of zinc nitrate, manganese sulfate, molybdenum acetate and cobalt chloride according to the ratio of the mass fraction of metal oxides in the desulfurization and arsenic removal agent being 20%, 5%, 8%, and 8%, and then add water to prepare The first metal mixed salt solution with a total salt mass concentration of 15%; followed by a urea solution with a mass fraction of 12% to precipitate the first metal, precipitation conditions: a water bath at 40°C, an alkali-salt molar ratio of 2:1, and a reaction time of 1.5 h;

[0045] S2: Take the copper nitrate solution and lead acetate according to the ratio of 35% and 8% of the metal oxide mass fraction in the desulfurization and arsenic removal agent, and then add water to prepare the second metal mixed salt with a total salt mass concentration of 12%. So...

Embodiment 2

[0049] This embodiment provides a composite metal oxide desulfurization and arsenic removal agent, obtained through the following steps:

[0050] S1: Weigh the calculated amount of zinc chloride, manganese nitrate, molybdenum nitrate and cobalt sulfate according to the ratio of the mass fraction of metal oxides in the desulfurization and arsenic removal agent being 25%, 5%, 5% and 5% respectively, and then add water to prepare The total salt mass concentration is the first metal mixed salt solution of 18%; then the first metal is precipitated by a sodium carbonate solution with a mass fraction of 12%, the precipitation condition: a water bath at 45°C, the alkali-salt molar ratio is 2:1, and the reaction time 1.5h;

[0051] S2: According to the mass fraction of metal oxides in the desulfurization and dearsenic agent being 32% and 10% respectively, take the calculated cupric chloride solution and lead nitrate, and then add water to prepare the second metal mixture with a total s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com