A kind of preparation method of Ganoderma lucidum spore powder and wheat germ composite slow-release microcapsules

A technology of Ganoderma lucidum spore powder and composite microcapsules, which is applied in the forming of food, the function of food ingredients, and food ingredients as encapsulants, etc. It can solve the problem that Ganoderma lucidum spore oil is easy to oxidize, microcapsules have not been prepared, and the embedding rate needs to be improved To achieve good sustained release effect, maintain functionality, and improve embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

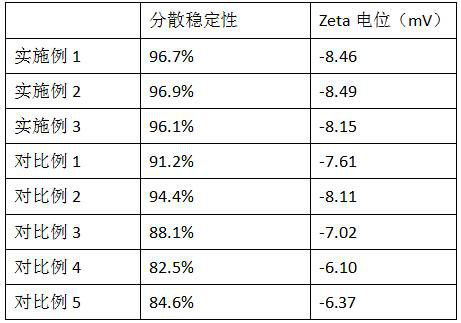

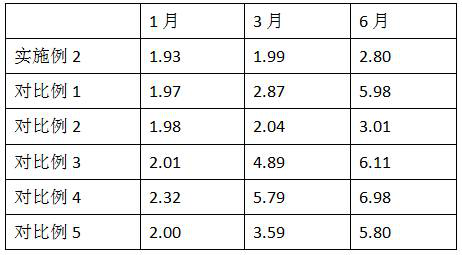

Examples

Embodiment 1

[0030] (1) Choose immature and disease-free green bananas, peel them, add 3 times the volume of ice water, beat at 2000rpm for 8 minutes, add pullulanase, cellulase and brewer's yeast, which account for 2% of the weight of green bananas, according to Composite enzyme with a mass ratio of 1:1:2, hydrolyze at 30-35°C for 1.5h, and then pass in carbon dioxide until the density of foam slurry is 0.6g / cm 3 , continue to heat-preserve the enzymatic hydrolysis for 1.5h, filter the slag with 4 layers of non-woven gauze to obtain green banana pulp, and vacuum concentrate the green banana pulp to a solid content of 35% at 70-80°C to obtain concentrated green banana pulp;

[0031] (2) Add sodium alginate and stachyose to the concentrated green banana pulp according to the mass ratio of 1:0.2:0.1, stir evenly, and make a mixed liquid for later use;

[0032] (3) Take wheat germ as raw material, dry it at 100-105°C for 15 minutes, and ultrafinely pulverize it to 800-1000 mesh after cooling...

Embodiment 2

[0037] (1) Select immature and disease-free green bananas, peel them, add 3-4 times the volume of ice water, beat at 2500rpm for 8 minutes, add pullulanase, cellulase and brewer's yeast accounting for 3% of the weight of green bananas According to the compound enzyme composed of the mass ratio of 1:1:2, enzymolyze at 30-35°C for 1.5h, and then pass in carbon dioxide until the density of foam slurry is 0.7g / cm 3 , continue to heat-preserve and enzymatically hydrolyze for 1.5h, filter and remove slag with 4 layers of non-woven gauze to obtain green banana pulp, and vacuum concentrate the green banana pulp at 70-80°C to a solid content of 38%, to obtain concentrated green banana pulp;

[0038] (2) Add sodium alginate and stachyose to the concentrated green banana pulp according to the mass ratio of 1:0.2:0.1, stir evenly, and make a mixed liquid for later use;

[0039] (3) Take wheat germ as raw material, dry it at 100-105°C for 20 minutes, and ultrafinely pulverize it to 1000 mes...

Embodiment 3

[0043] (1) Choose immature and disease-free green bananas, peel them, add 4 times the volume of ice water, beat at 2000rpm for 8 minutes, add pullulanase, cellulase and brewer's yeast, which account for 3% of the weight of green bananas, according to Composite enzyme with a mass ratio of 1:1:2, hydrolyze at 30-35°C for 1.5h, and then pass in carbon dioxide to form a foam slurry with a density of 0.8g / cm 3 , continue to heat-preserve and enzymatically hydrolyze for 1.5h, filter and remove slag with 4 layers of non-woven gauze to obtain green banana pulp, and vacuum concentrate the green banana pulp to a solid content of 40% at 70-80°C to obtain concentrated green banana pulp;

[0044] (2) Add sodium alginate and stachyose to the concentrated green banana pulp according to the mass ratio of 1:0.2:0.1, stir evenly, and make a mixed liquid for later use;

[0045] (3) Take the raw material wheat germ, dry it at 100-105°C for 15-20 minutes, and after cooling, ultrafinely pulverize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com