A kind of non-yellowing thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of modified polyurethane, can solve problems such as physical and mechanical properties decline, human body influence, yellowing, etc., to achieve improved yellowing resistance, good yellowing resistance, and increased compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

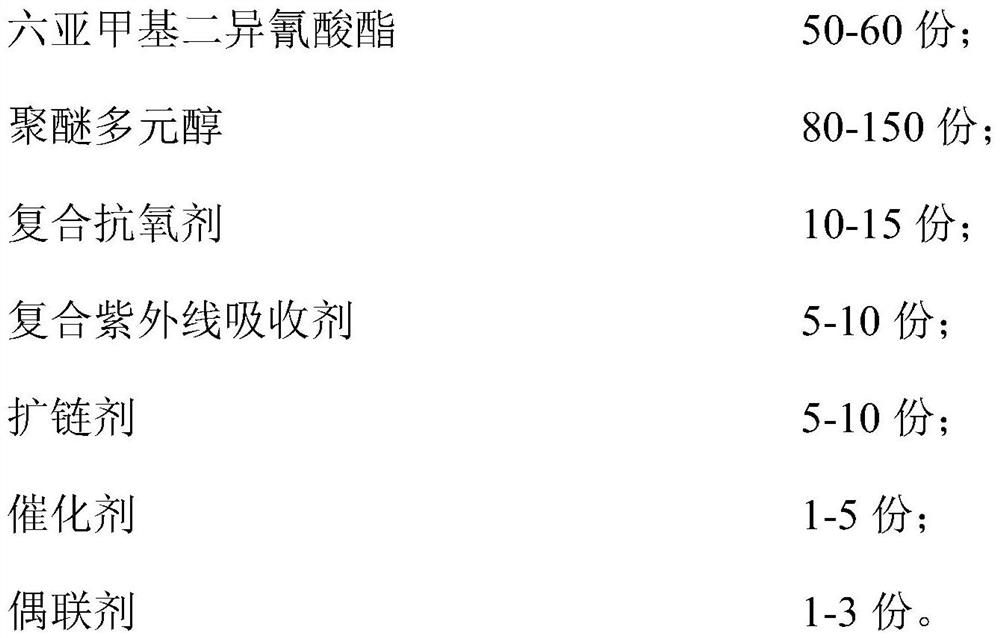

[0046] A non-yellowing thermoplastic polyurethane elastomer, consisting of the following components in parts by weight:

[0047]

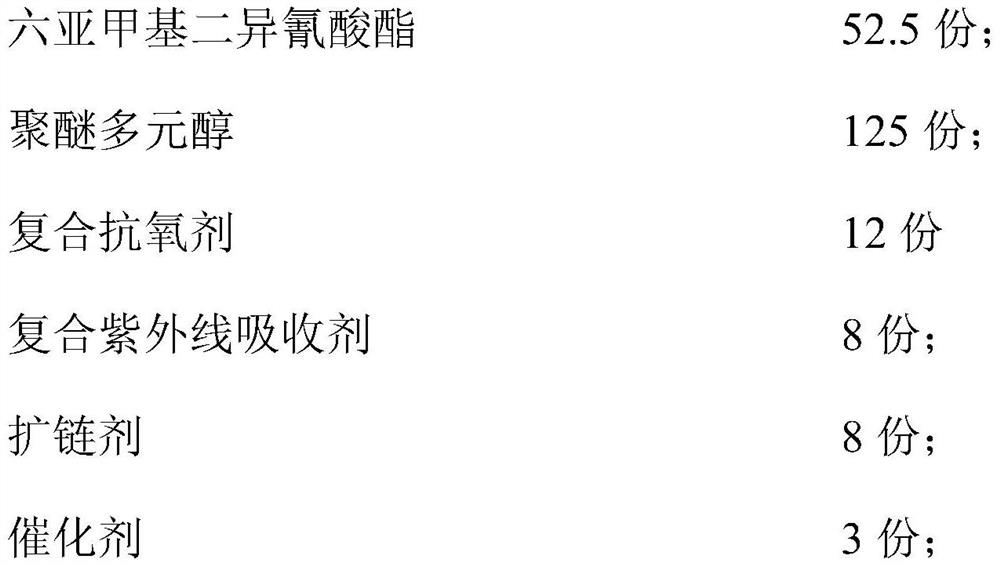

[0048]

[0049] Among them, the polyether polyol is polypropylene glycol with an average molecular weight of 1000; the molar ratio of hexamethylene diisocyanate to polyether polyol is 2.5:1; the composite antioxidant is tri-(2,4-ditertiary phosphite A composition composed of butylphenyl) ester, bis(3,5-di-tert-butyl-4-hydroxybenzyl) sulfide and tri(hexadecyl) ester in a mass ratio of 1:5:2; The ultraviolet absorber is a composition composed of nano silicon dioxide, 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole and microcrystalline cellulose in a mass ratio of 2:4:1; The chain agent is ethylenediamine; the catalyst is dibutyltin dioctoate; the coupling agent is vinyltriethoxysilane.

[0050] The preparation method is as follows:

[0051] (1) Mix composite antioxidant, composite UV absorber, coupling agent, then add chain extender and catalyst...

Embodiment 2-7

[0054] The only difference from Example 1 is that in this example, tris-(2,4-di-tert-butylphenyl) phosphite, bis(3,5-di-tert-butyl-4-hydroxybenzyl) The mass ratio of sulfide and three (hexadecyl) esters is 1:3:1 (Example 2), 1:5:2 (Example 3), 1:1:1 (Example 4), 1:7 :1 (Example 5), 1:3:0.5 (Example 6), 1:5:4 (Example 7)

Embodiment 8-13

[0056] The only difference with Example 1 is that in this example, the mass ratio of nano silicon dioxide, 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole and microcrystalline cellulose is 2:2:1 (Example 8), 4:4:1 (Example 9), 1:2:1 (Example 10), 5:4:1 (Example 11), 2:1:1 ( Example 12), 4:5:1 (Example 13).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com