Isoliquiritigenin nanosuspension and preparation method and application thereof

A nano-suspension and isoliquiritigenin technology, which is applied in liquid transportation, pharmaceutical formula, emulsion transportation, etc., can solve the problem that the isoliquiritigenin nano-suspension does not meet the expected experimental effect, and achieves the improvement of cumulative dissolution rate , low cost, and the effect of improving the ability of apoptosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, preparation of isoliquiritigenin nanosuspension

[0046] Isoliquiritigenin nanosuspension (ISL-NS): Weigh 0.25g of isoliquiritigenin, add it to 50ml of distilled water, and stir magnetically for 15 minutes to obtain a coarse suspension. Before grinding, add 140ml of zirconia grinding beads with a particle size of 0.6-0.8mm into the grinding chamber, and grind for 45 minutes at 2000rpm. sexual charge.

[0047] Isoliquiritigenin Nanosuspension 1 (HPC SSL-SDS-ISL-NS): Weigh 0.05g of hydroxypropyl cellulose, 0.05g of sodium lauryl sulfate, add 50ml of distilled water, and stir to obtain a stabilizer solution. Add 1 g of isoliquiritigenin under a magnetic stirrer, and stir magnetically for 15 minutes to obtain a coarse suspension. Before grinding, add 140ml of yttrium-stabilized zirconia grinding beads with a particle size of 0.6-0.8mm into the grinding chamber, and grind for 45 minutes at a speed of 2000rpm. After the obtained sample is diluted 10 times with...

Embodiment 2

[0053] Example 2, Preparation of Isoliquiritigenin Micro and Nano Suspensions

[0054] Isoliquiritigenin Nanosuspension 2 (HPC SSL-ISL-NS): Weigh 0.1g of hydroxypropyl cellulose (HPC), add 50ml of distilled water, stir evenly to obtain a stabilizer solution, add 0.25g of iso Liquiritigenin, magnetically stirred for 15 minutes to obtain a coarse suspension. Before grinding, add 140ml of yttrium-stabilized zirconia grinding beads with a particle size of 0.6-0.8mm into the grinding chamber, grind at 2000rpm for 45min, and dilute the obtained sample 10 times with purified water to obtain the isoliquiritigenin nanosuspension particles The diameter is 238.1nm, and the potential is -16.83mV.

[0055] Isoliquiritigenin Nanosuspension 3 (PVP K30-ISL-NS): Weigh 0.1g of povidone K30, add 50ml of distilled water, stir evenly to obtain a stabilizer solution, add 0.25g of isoliquiritigenin under magnetic stirring, and magnetically Stir for 15 min to obtain a coarse suspension. Before gri...

Embodiment 3

[0066] Example 3. Freeze-dried powder and characterization of isoliquiritigenin nanosuspension.

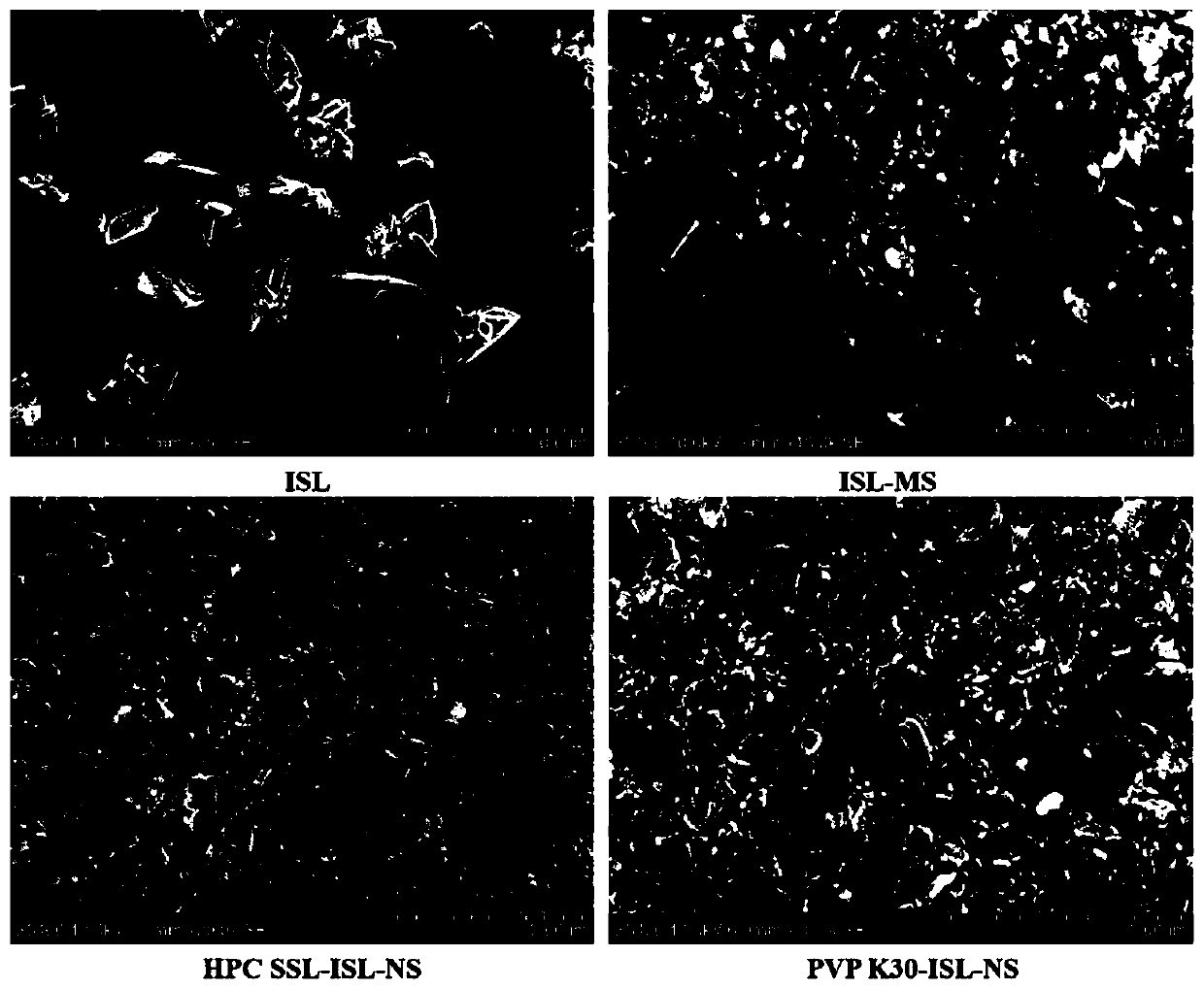

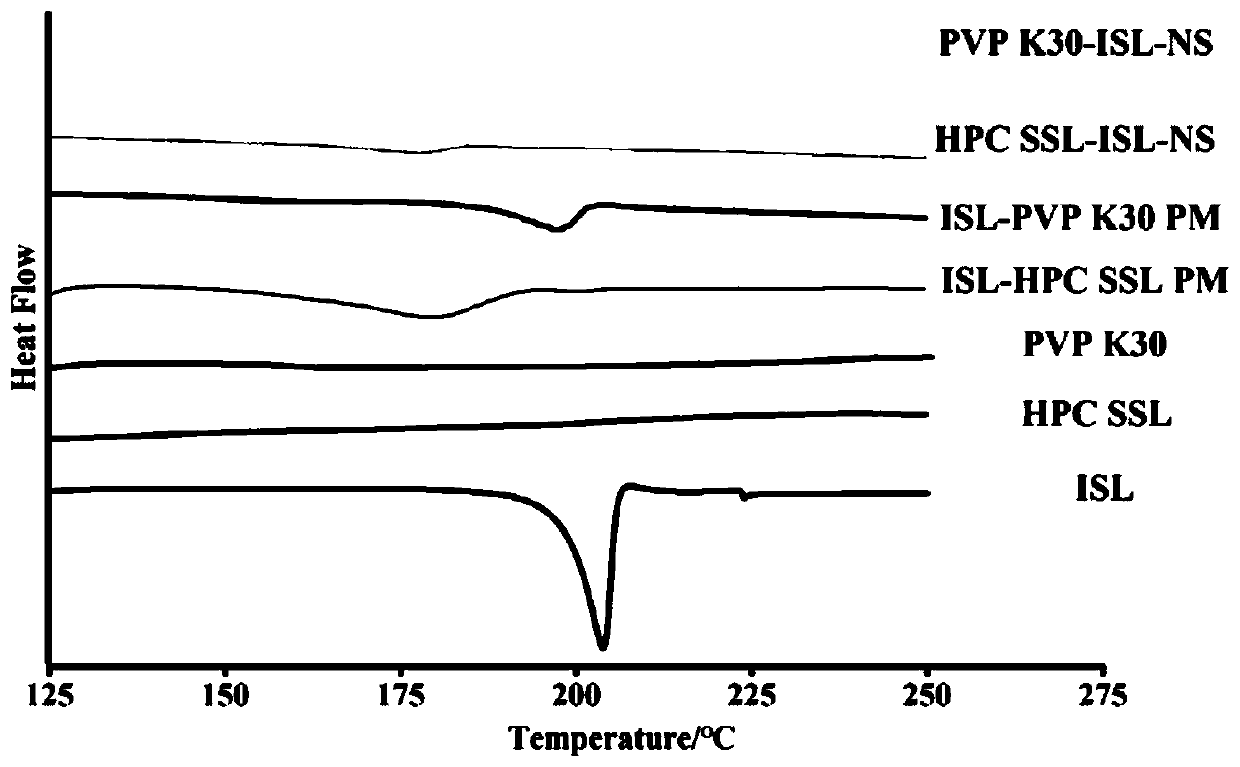

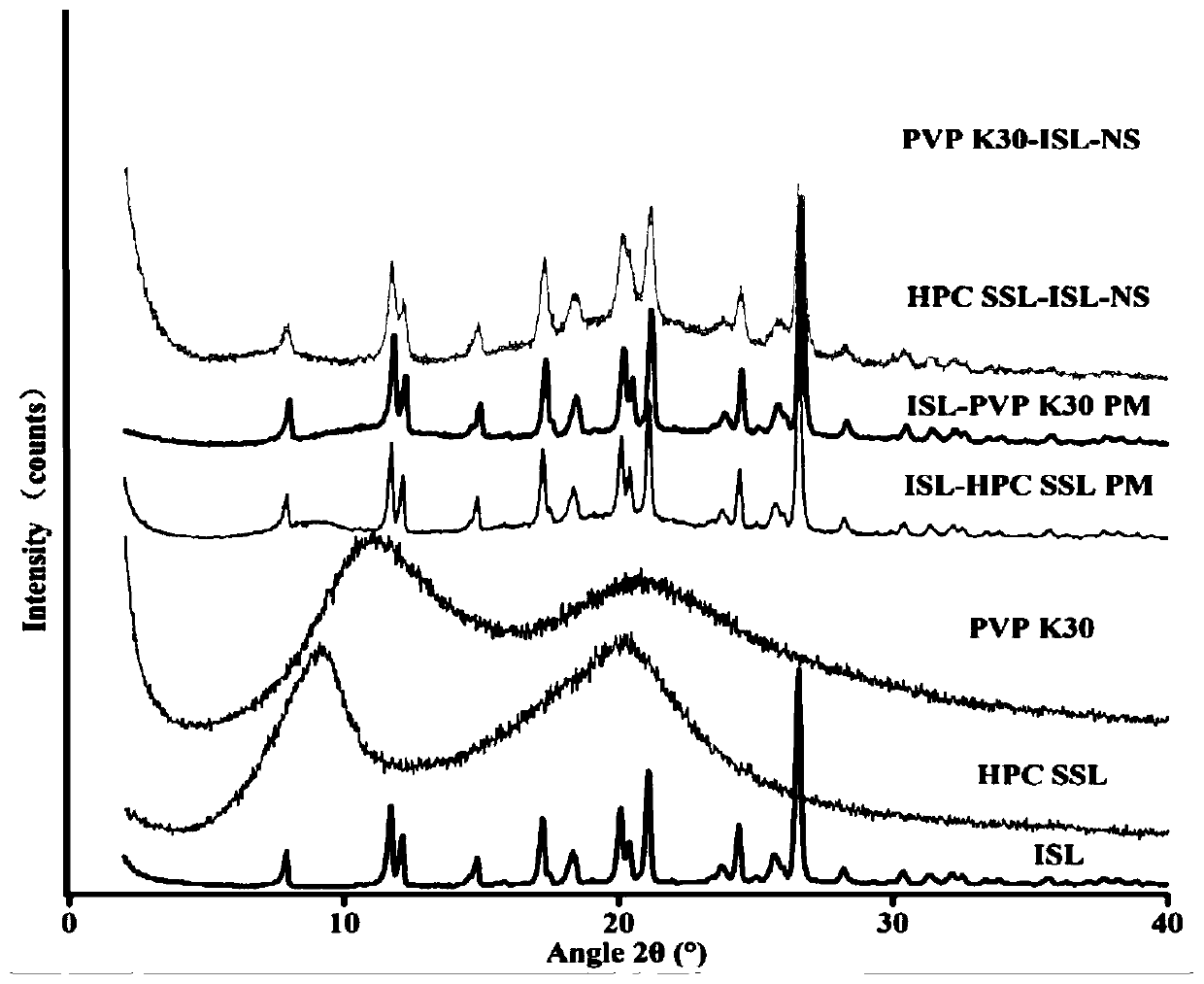

[0067] Add 2% lyoprotectant lactose to the isoliquiritigenin nanosuspension, mix well, pre-freeze at -80°C for 12h, transfer to a freeze dryer, freeze at -40°C for 8h, and finally freeze at 12°C Under heating and sublimation for 4 hours, the freeze-dried powder of isoliquiritigenin nanosuspension was obtained. Freeze-dried powder is characterized by scanning electron microscopy, differential scanning calorimeter (DSC), X-ray diffraction (XRD), Fourier transform infrared spectrometer (FTIR) and X-ray photoelectron spectroscopy (XPS), and the results are as follows: figure 1 , 2, 3, 4, 5.

[0068] From figure 1It can be seen from the figure that the isoliquiritigenin API exists in square, columnar and irregular forms, and the form of ISL-MS is small particles, while the form of HPC SSL-ISL-NS and PVP K30-ISL-NS is in the form of irregular The flake-like form exists, and it can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com