System and method for recovering titanium tetrachloride from titanium tetrachloride suspension liquid

A titanium tetrachloride and suspension technology is applied in the system field of recovering titanium tetrachloride from titanium tetrachloride suspension, which can solve the problem that the separation process is difficult to optimize the separation effect, the control variables cannot achieve the separation effect, and the recovery of titanium tetrachloride Due to the limited amount of titanium and other problems, the effect of saving heating power consumption and processing time, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

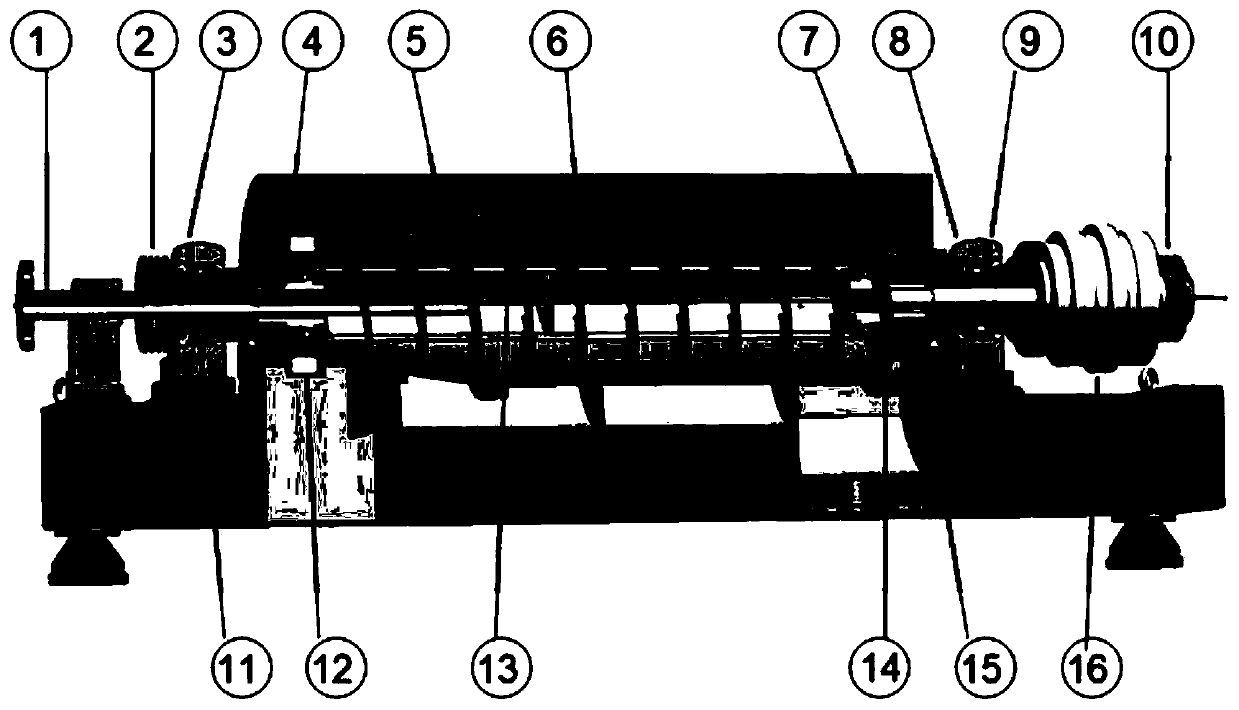

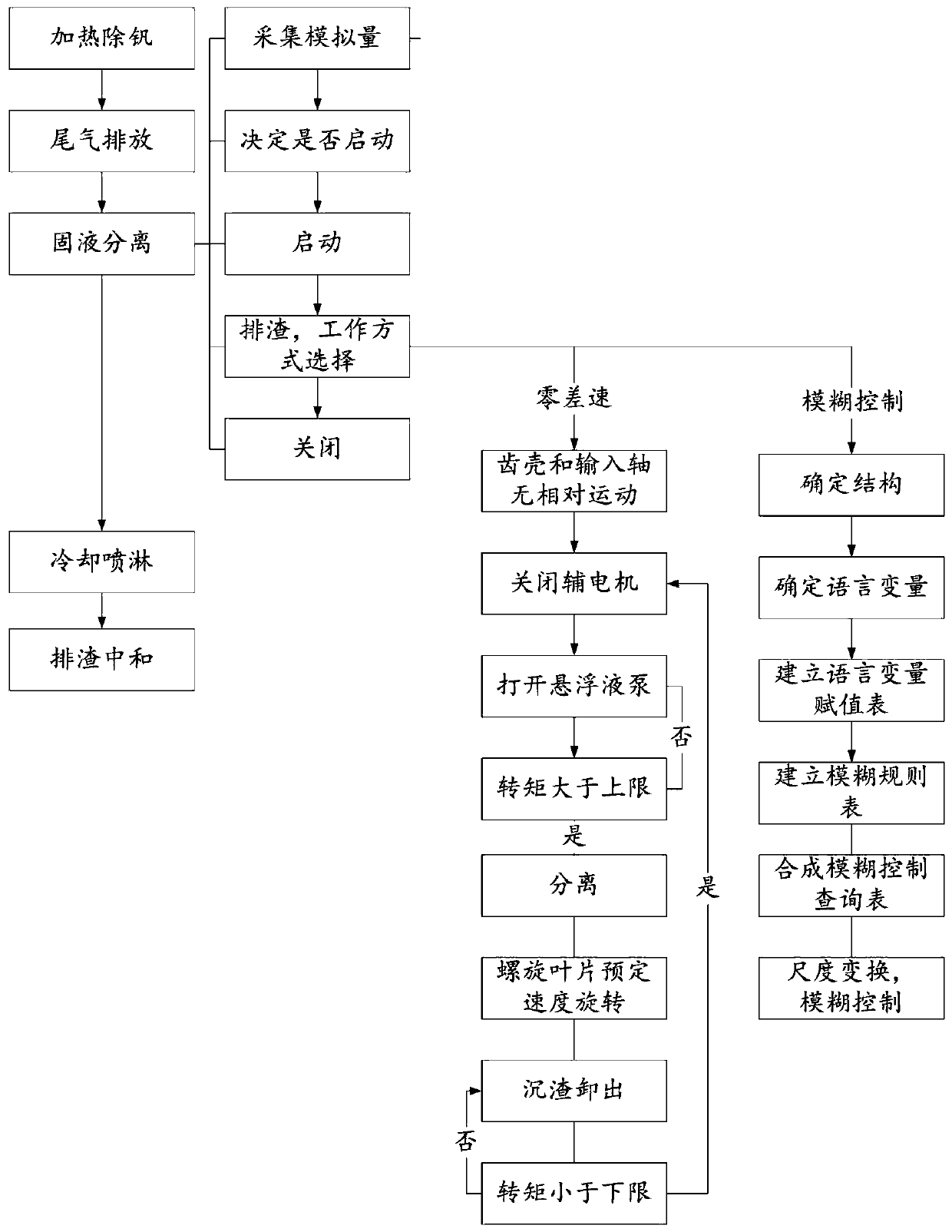

[0031] Embodiments of the present invention refer to Figure 1-2 shown.

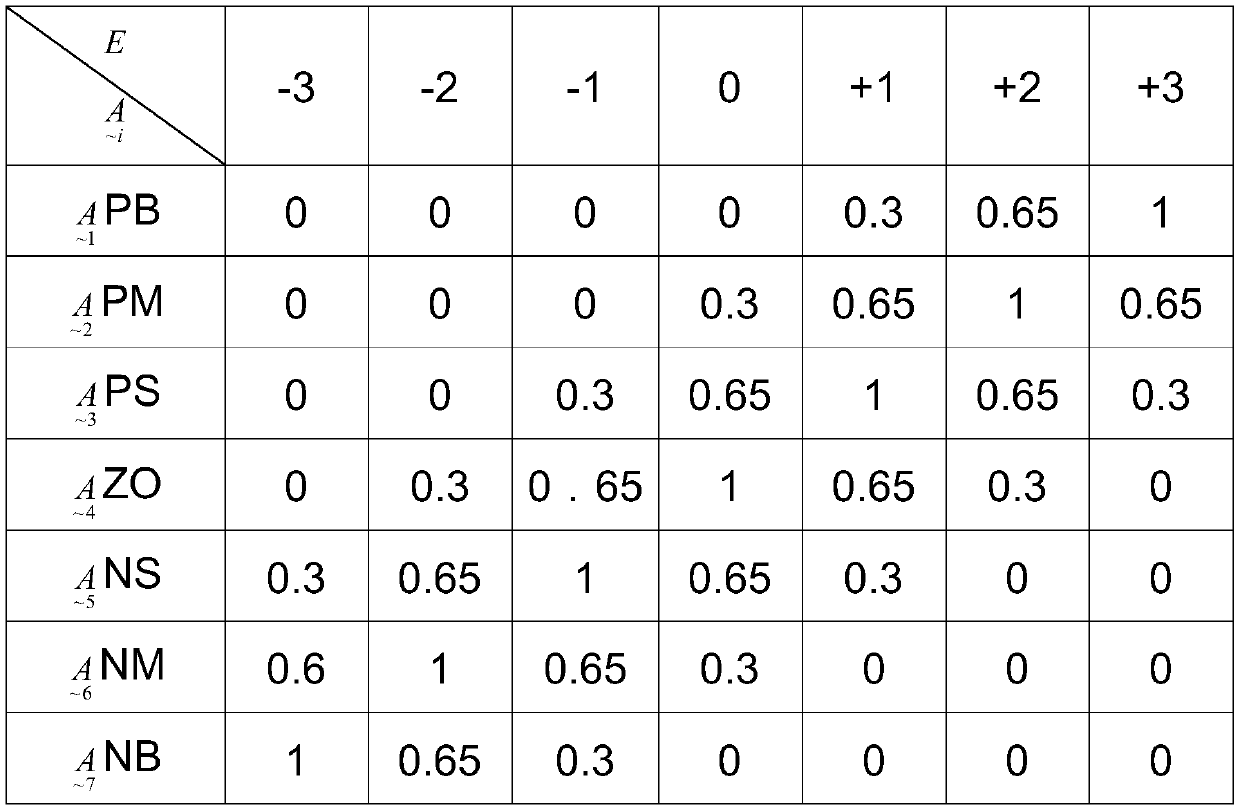

[0032] A system for recovering titanium tetrachloride from a titanium tetrachloride suspension, comprising a vanadium removal reactor, a suspension pump, a spiral plate heat exchanger, a buffer tank, an exhaust gas discharge device, a suspension centrifuge, a chlorination furnace cooling conduit, Liquid pump, cyclone separator, chlorination furnace slag discharge tank, after titanium tetrachloride goes through the vanadium removal reactor to remove vanadium from mineral oil, the suspension is pumped to the spiral plate heat exchanger, and the temperature is cooled by the spiral plate heat exchanger The vanadium-removed suspension enters the buffer tank, and an exhaust gas discharge device is installed on the top of the buffer tank. The gaseous silicon tetrachloride in the buffer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com