Nickel-cobalt-molybdenum ternary metal sulfide as well as preparation method and application thereof

A ternary metal and sulfide technology, used in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of insufficiency of morphology, unfavorable electrode material and electrolyte infiltration, general electrochemical performance, etc. Specific capacity and energy density, good commercial application value, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of nickel cobalt molybdenum ternary metal sulfide, its preparation method comprises the following steps:

[0039] 1) Fully dissolve 0.375g nickel chloride and 0.125g cobalt chloride in 150mL deionized water to obtain nickel chloride-cobalt chloride aqueous solution, fully dissolve 0.545g ammonium thiomolybdate in 50mL absolute ethanol and 200mL deionized The ethanol-water solution of ammonium thiomolybdate was obtained in the mixed solvent composed of water, and the nickel chloride-cobalt chloride aqueous solution was slowly added dropwise to the ethanol-water solution of ammonium thiomolybdate while stirring at room temperature, and the stirring rate was 350r / min, the stirring time is 6h, then vacuum filtration, wash the obtained solid three times with ethanol and distilled water respectively, and then vacuum dry at 80°C for 12h;

[0040] 2) Put the product of step 1) into a tube furnace, place it in a nitrogen atmosphere, heat up to 400°C at a rate of 2°C / min,...

Embodiment 2

[0053] A kind of nickel cobalt molybdenum ternary metal sulfide, its preparation method comprises the following steps:

[0054] 1) operation is with the step 1) of embodiment 1;

[0055] 2) Put the product of step 1) into a tube furnace, place it in a nitrogen atmosphere, heat up to 400°C at a rate of 2°C / min, and then calcinate for 2 hours to obtain a massive nickel-cobalt-molybdenum ternary metal sulfide crude product;

[0056] 3) Disperse the product of step 2) in an ethanol-water solution of NaOH with a concentration of 2mol / L (the volume ratio of ethanol and water is 7:1), then transfer the material to a hydrothermal kettle, and react at a constant temperature of 200°C for 24h, and then Carry out centrifugation, the solid obtained by centrifugation is washed with water, then placed in 80 ℃ oven drying 12h, obtain nickel cobalt molybdenum ternary metal sulfide (Ni 0.75 co 0.25 MoS 4 ).

[0057] Performance Testing:

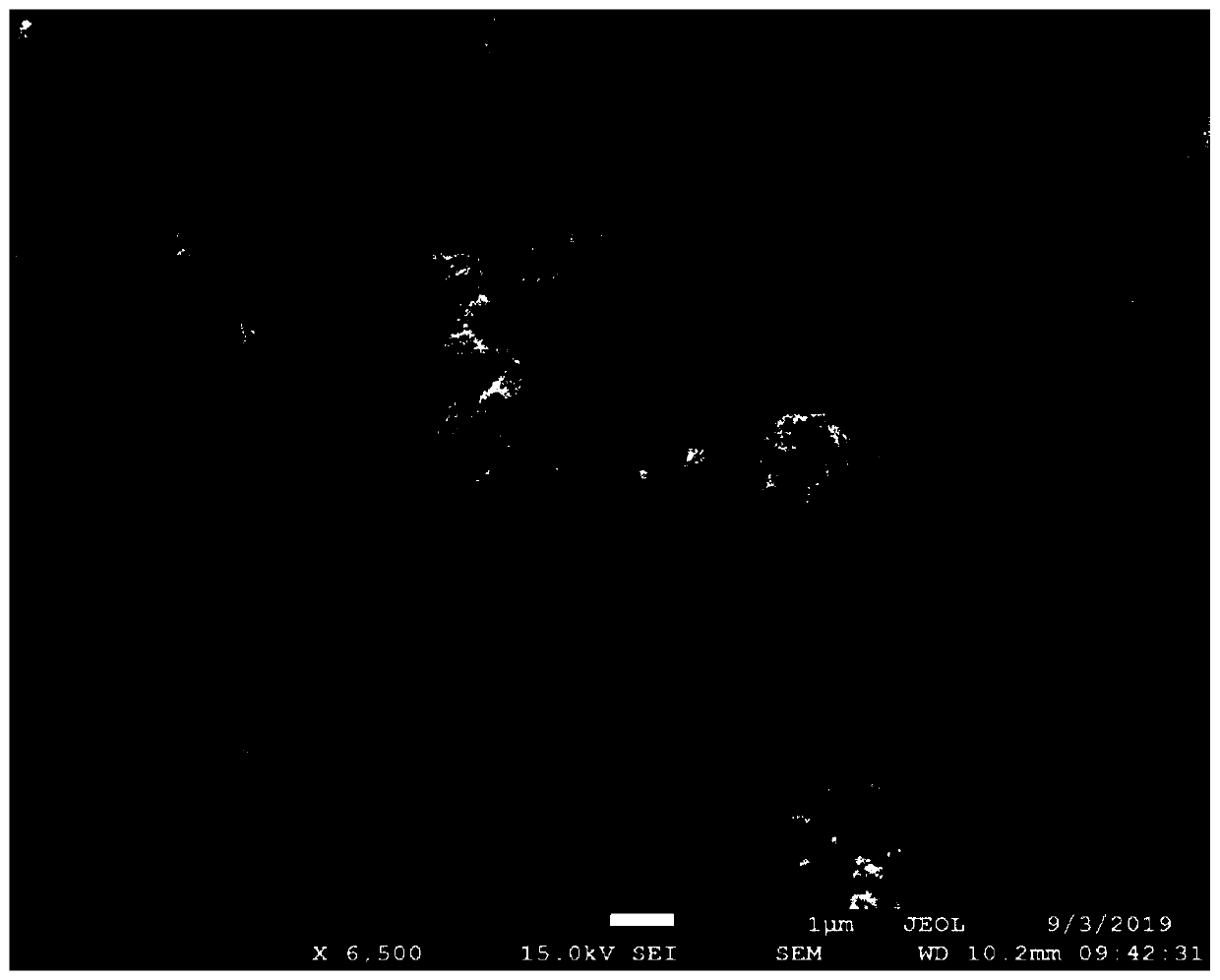

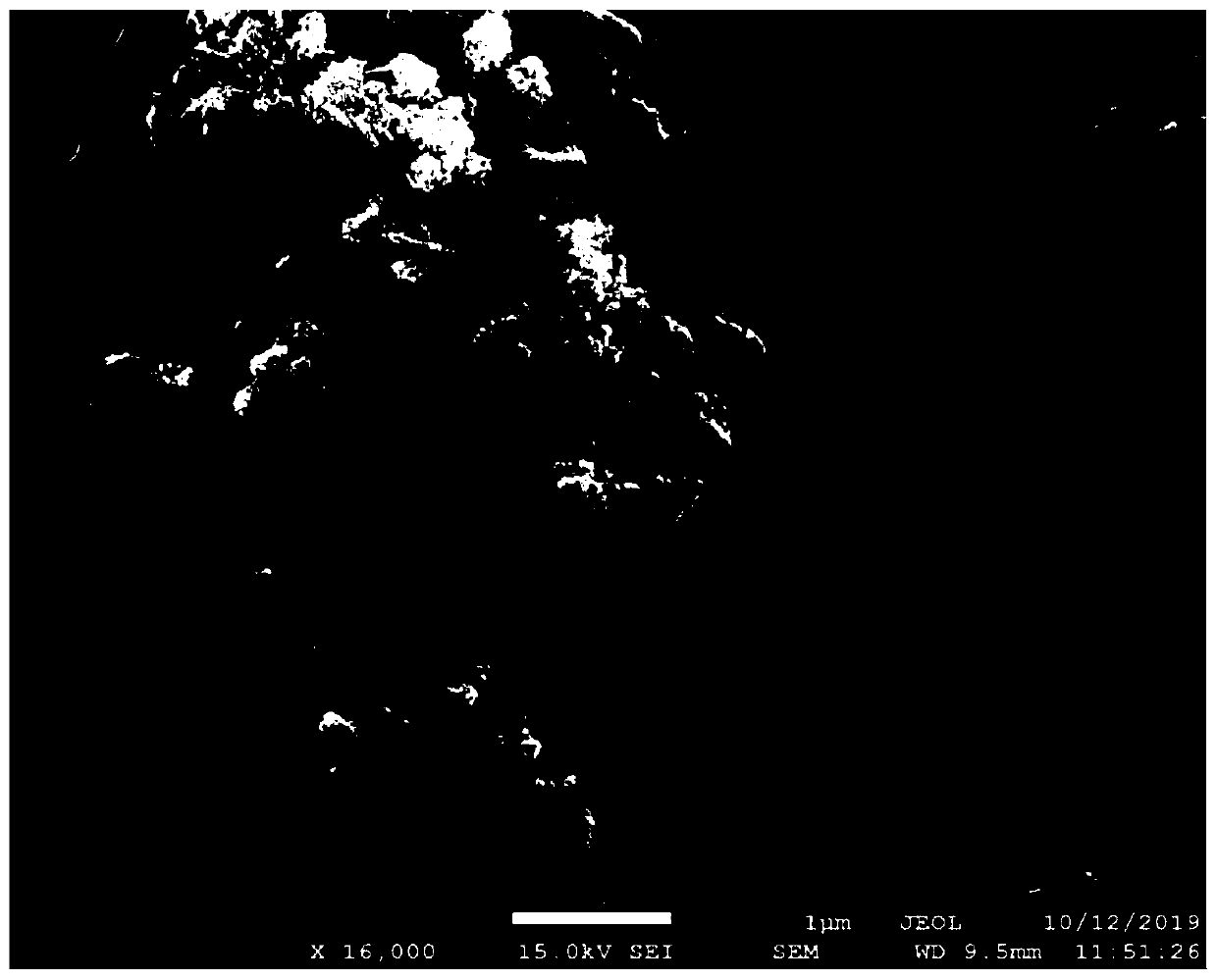

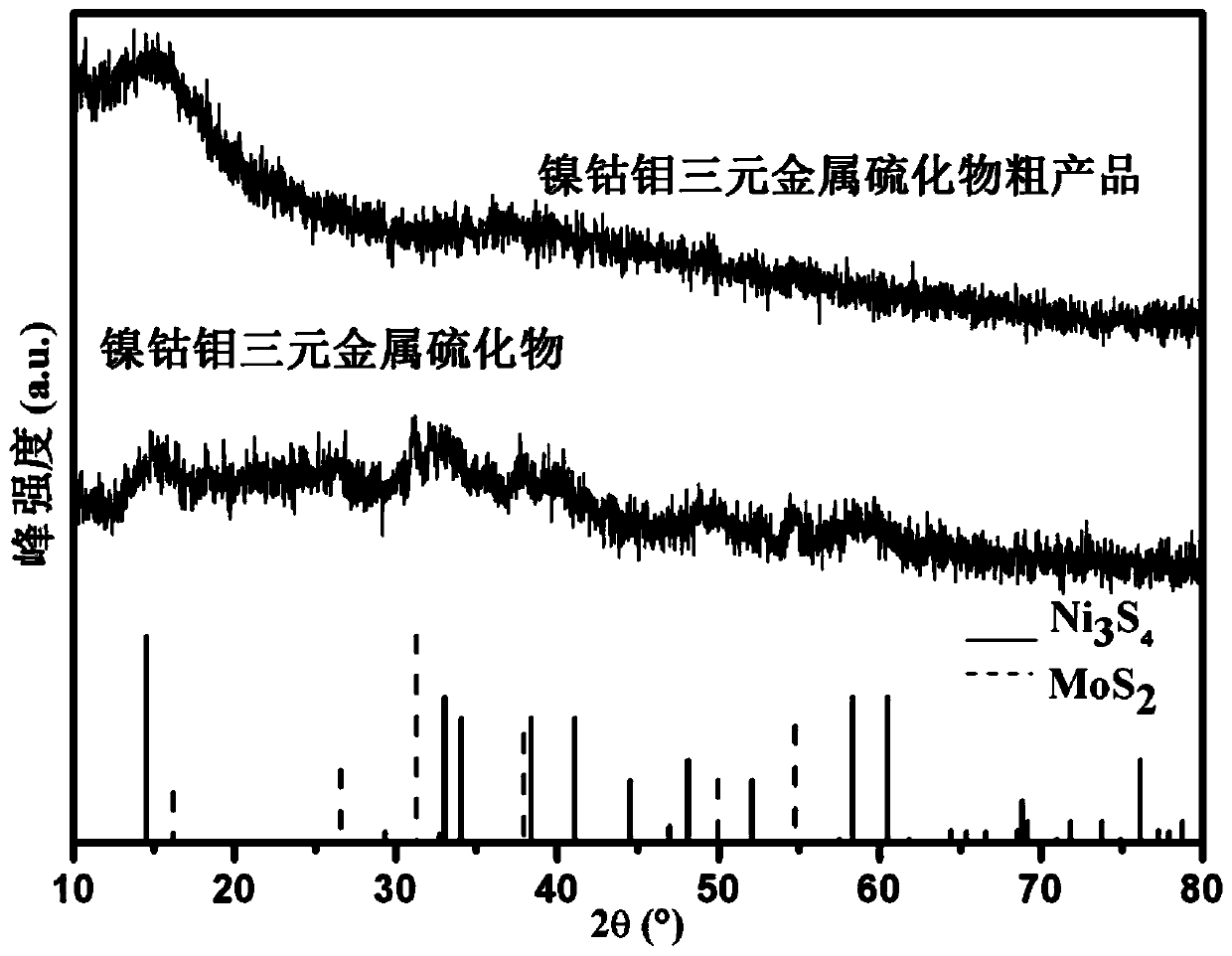

[0058] 1) SEM image of nickel-cobalt-molybdenum ter...

Embodiment 3

[0064] A kind of nickel cobalt molybdenum ternary metal sulfide, its preparation method comprises the following steps:

[0065] 1) operation is with the step 1) of embodiment 1;

[0066] 2) Put the product of step 1) into a tube furnace, place it in a nitrogen atmosphere, heat up to 400°C at a rate of 2°C / min, and then calcinate for 2 hours to obtain a massive nickel-cobalt-molybdenum ternary metal sulfide crude product;

[0067] 3) Disperse the product of step 2) in an ethanol-water solution of NaOH with a concentration of 2mol / L (the volume ratio of ethanol and water is 7:1), then transfer the material to a hydrothermal kettle, react at a constant temperature of 180°C for 24h, and then Carry out centrifugation, the solid obtained by centrifugation is washed with water, then placed in 80 ℃ oven drying 12h, obtain nickel cobalt molybdenum ternary metal sulfide (Ni 0.75 co 0.25 MoS 4 ).

[0068] Performance Testing:

[0069] 1) The constant current charge and discharge cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com