Platinum alloy catalyst, preparation method thereof and application of platinum alloy catalyst in fuel cell cathode catalyst

A catalyst and platinum alloy technology, which is applied in the synthesis field of fuel cell cathode catalysts, can solve problems such as carcinogenicity, complicated preparation process, and difficult storage, and achieve strong oxygen reduction catalytic activity, simple preparation process, and low drug cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1. Take 14.4g of glucose and make 130ml of solution with deionized water, add 10ml of platinum nitrate containing 0.47g, and sonicate the mixed solution for 10min.

[0064] 2. Add ammonia water to adjust the pH value of the system to 9.

[0065] 3. Stir and heat the mixed solution to 60°C and keep it warm for 10min, add 20ml of Vulcan XC-72R deionized water suspension containing 0.4g to the above solution, stir for 30min, then raise the temperature to 80°C, react for 2h and then add and contain 0.16g of cobalt nitrate hexahydrate solution 10ml, and keep stirring during the reaction for 4 hours.

[0066] 4. Subsequently, the above mixture is suction filtered and washed to obtain a filter cake.

[0067] 5. Put the filter cake into 100ml deionized water, sonicate for 10min to obtain a mixed solution, add 2g of ascorbic acid, and sonicate again for 30min.

[0068] 6. Then raise the temperature of the solution in step 5 to 80°C, and react for 6 hours, ensuring constant sti...

Embodiment 2

[0073] 1. Take 3.1g of glucose and make 70ml solution with deionized water, add 20ml solution containing 0.98g sodium hexachloroplatinate hexahydrate, and ultrasonicate the mixed solution for 20min.

[0074] 2. Add citric acid to adjust the pH value of the system to 3.

[0075] 3. Stir and heat the mixed solution to 55°C and keep it warm for 30min. Add 50ml of 1.77g Vulcan XC-72 deionized water suspension to the above solution, stir for 20min, then heat up to 95°C, react for 3h and add 0.4g 10ml of nickel acetate tetrahydrate solution was reacted for another 2 hours, and constant stirring was ensured during this period.

[0076] 4. Subsequently, the above mixture is suction filtered and washed to obtain a filter cake.

[0077] 5. Put the filter cake into 200ml of deionized water, sonicate for 30min to obtain a mixed solution, add 15.3g of sodium citrate, and sonicate again for 10min.

[0078] 6. Then raise the temperature of the solution in step 5 to 95°C, and react for 7 ho...

Embodiment 3

[0083] 1. Take 25g of glucose and make 150ml of solution with deionized water, add 30ml of aqueous solution containing 1.8g of chloroplatinic acid, and ultrasonically mix at 40°C for 10min.

[0084] 2. Add sodium hydroxide to adjust the pH value of the system to 10.

[0085] 3. Stir the mixed solution and heat it to 60°C and keep it warm for 15min. Take 10ml of the deionized water suspension containing 0.1g of acetylene black, add it to the above solution, stir for 20min, then raise the temperature to 85°C, react for 4h, then add 0.18g 10ml of ruthenium trichloride solution, and then reacted for 3h, ensuring constant stirring during this period.

[0086] 4. Subsequently, the above mixture is suction filtered and washed to obtain a filter cake.

[0087] 5. Put the filter cake into 100ml of deionized water, sonicate for 10 minutes to obtain a mixed solution, add 4g of glycerin, and sonicate again for 20min.

[0088] 6. Then, the temperature of the solution in step 5 was raised...

PUM

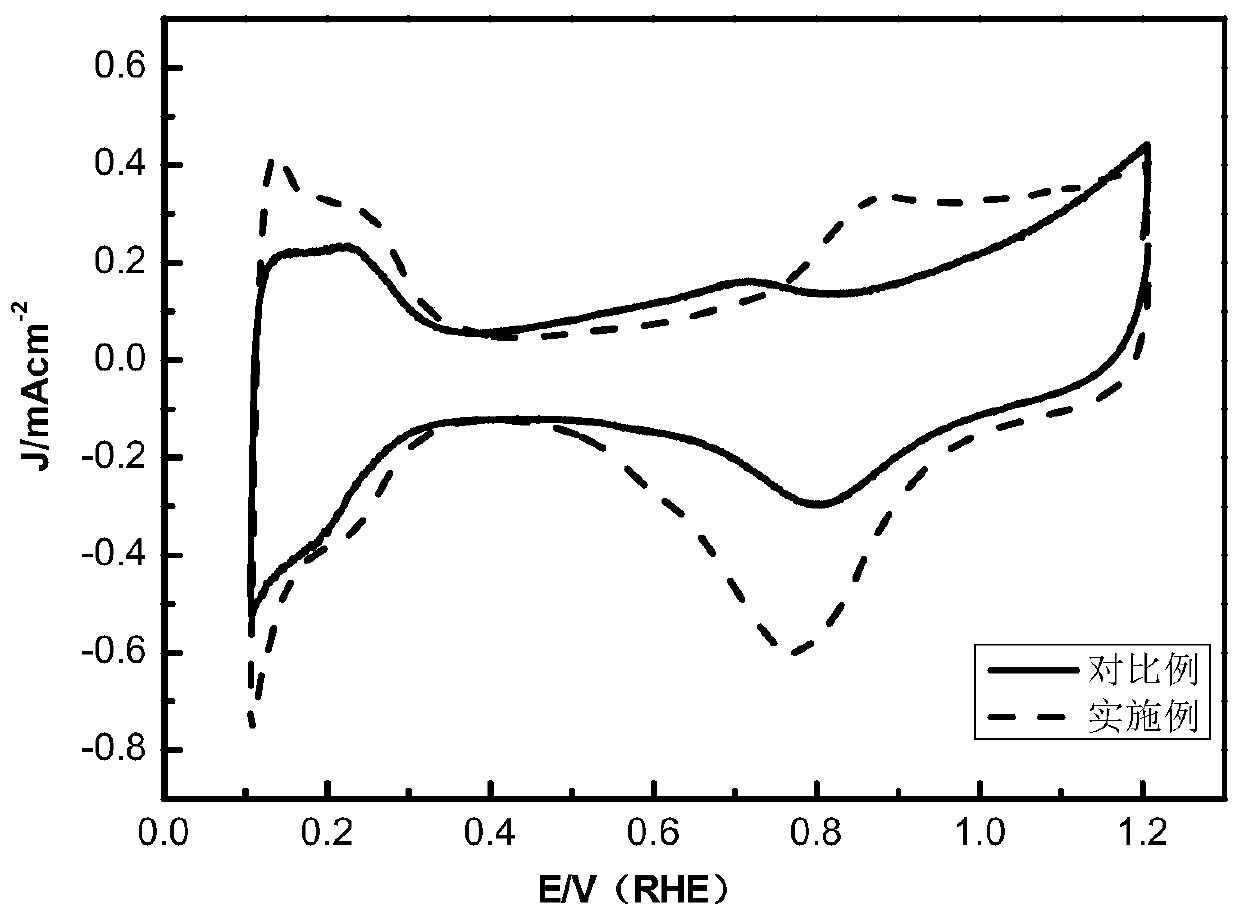

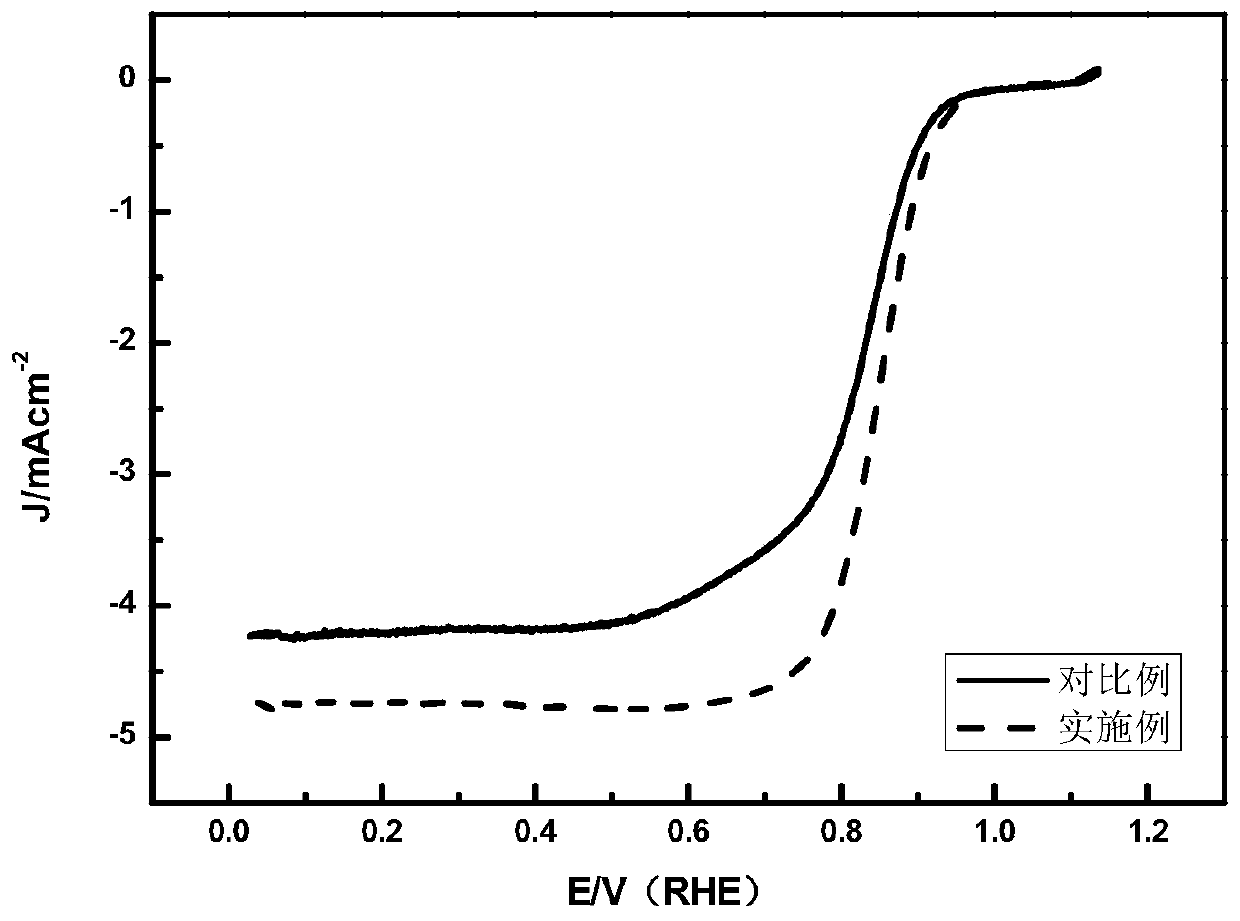

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Active area | aaaaa | aaaaa |

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com