Lubricating grease containing modified graphene, and preparation method thereof

A graphene and grease technology, applied in the field of modified graphene-containing grease and its preparation, can solve the problems of grease colloidal stability, poor dropping point friction reduction performance, poor graphene dispersion uniformity, etc. Dropping point and anti-friction properties, improved compatibility, improved uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

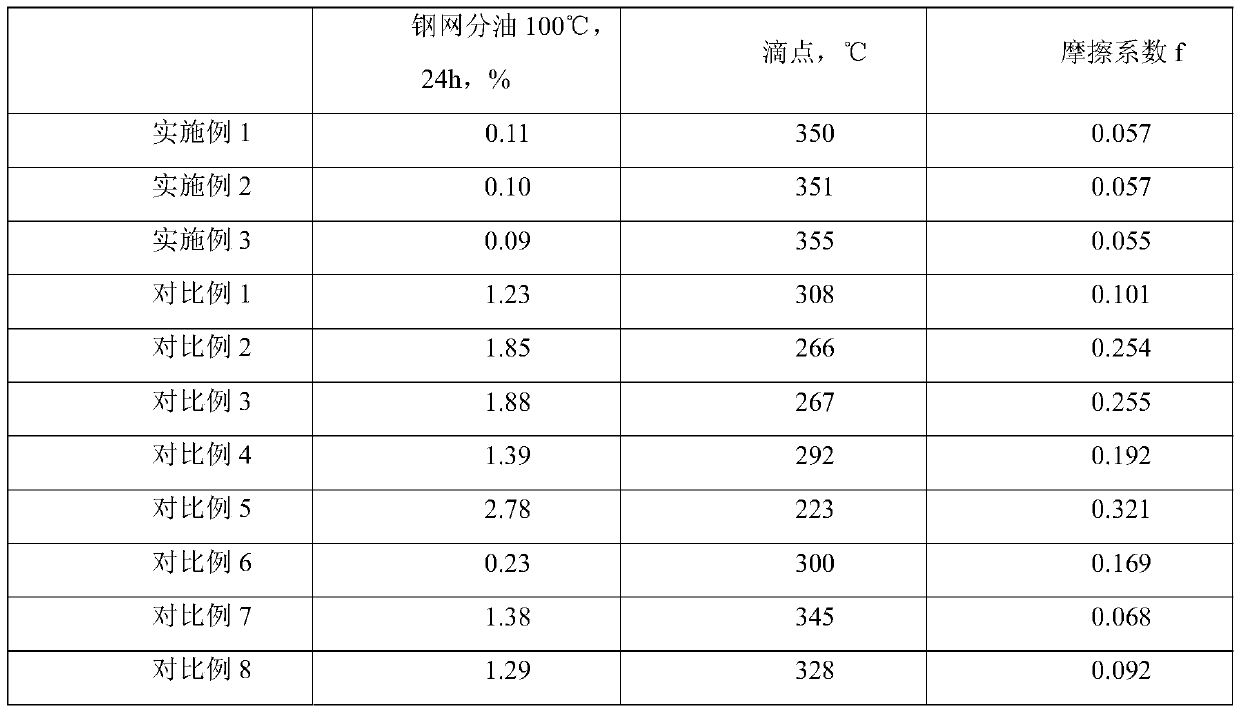

Examples

Embodiment 1

[0031]A preparation method of lubricating grease containing modified graphene. First, mix the first part of base oil with high molecular acid and low molecular acid, heat, add barium hydroxide, saponify, refine, cool, and add the pre-mixed second Two parts of base oil and modified graphene are stirred evenly and ground into grease to obtain the described grease containing modified graphene; wherein the modified graphene is prepared by the following method: first oxidized Graphene is used as a raw material for silicon, boron, and phosphorus co-doping, and then the multi-doped graphene is obtained through reduction treatment, and then the multi-doped graphene is organically modified by 7-octenyl trichlorosilane, and then The obtained intermediate product is polymerized with isooctyl acrylate, and finally the polymerized product is mixed with 7,7,8,8-tetracyano-p-dimethylbenzoquinone to obtain the modified graphene.

[0032] The mass ratio of the first part of base oil, high mole...

Embodiment 2

[0047] A preparation method of lubricating grease containing modified graphene. First, mix the first part of base oil with high molecular acid and low molecular acid, heat, add barium hydroxide, saponify, refine, cool, and add the pre-mixed second Two parts of base oil and modified graphene are stirred evenly and ground into grease to obtain the described grease containing modified graphene; wherein the modified graphene is prepared by the following method: first oxidized Graphene is used as a raw material for silicon, boron, and phosphorus co-doping, and then the multi-doped graphene is obtained through reduction treatment, and then the multi-doped graphene is organically modified by 7-octenyl trichlorosilane, and then The obtained intermediate product is polymerized with isooctyl acrylate, and finally the polymerized product is mixed with 7,7,8,8-tetracyano-p-dimethylbenzoquinone to obtain the modified graphene.

[0048] The mass ratio of the first part of base oil, high mol...

Embodiment 3

[0063] A preparation method of lubricating grease containing modified graphene. First, mix the first part of base oil with high molecular acid and low molecular acid, heat, add barium hydroxide, saponify, refine, cool, and add the pre-mixed second Two parts of base oil and modified graphene are stirred evenly and ground into grease to obtain the described grease containing modified graphene; wherein the modified graphene is prepared by the following method: first oxidized Graphene is used as a raw material for silicon, boron, and phosphorus co-doping, and then the multi-doped graphene is obtained through reduction treatment, and then the multi-doped graphene is organically modified by 7-octenyl trichlorosilane, and then The obtained intermediate product is polymerized with isooctyl acrylate, and finally the polymerized product is mixed with 7,7,8,8-tetracyano-p-dimethylbenzoquinone to obtain the modified graphene.

[0064] The mass ratio of the first part of base oil, high mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com