Hyaluronic acid hydrolase and encoding sequence thereof, and method for preparing oligomeric hyaluronate by using hyaluronic acid hydrolase

A technology of hyaluronic acid salt and hyaluronic acid, which is applied in the fields of genetic engineering and enzyme engineering, can solve the problems of inapplicability to industrial production, high cost, poor activity of hyaluronidase, etc., and achieve the benefits of industrial production and efficiency improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example is used to prepare a genetically engineered strain containing the nucleotide sequence of hyaluronan hydrolase.

[0062] 1. Recombine the sequence containing the sequence SEQ ID NO.1 (synthesized by Changzhou Jiyu Biotechnology Co., Ltd.) synthesized by the whole gene into the yeast expression vector pPIC9k (purchased from Invitrogen Co., Ltd.) after restriction endonucleases EcoRI and NotⅠ. ), and transformed into E.coli Top10 competent state (purchased from Beijing Quanshijin Biotechnology Co., Ltd.);

[0063] Place E.coli Top10 in LB liquid medium, culture overnight at 37°C with shaking at 160rpm, and extract the recombinant plasmid;

[0064] The recombinant plasmid was linearized using the restriction enzyme SacI.

[0065] 2. Introduce the linearized recombinant plasmid into Pichia pastoris

[0066] A single colony of Pichia Pastoris GS115 (Pichia pastoris GS115, purchased from Invitrogen) was picked into YPD medium for activation, and the activated GS...

Embodiment 2

[0071] In this example, the recombinant engineering strain prepared in Example 1 was used to prepare hyaluronan hydrolase.

[0072] Take the recombinant engineered bacteria prepared in Example 1 and streak on the YPD plate, 30 ° C, and culture overnight; pick a single colony with a diameter of 1 mm on the plate and inoculate it into 50 mL of YPD liquid medium, 30 ° C, 200 rpm shaking culture for 24 hours, OD 600 reach 5, inoculate into 300mL YPD liquid medium with 10% inoculum size, the shake flask used is a 1L Erlenmeyer flask, 30 ℃, 200rpm shaker shaking culture, when OD 600 The cultivation was stopped when reaching 12.

[0073] After the fermentation medium is prepared per liter of material, it is poured into a 30L fermenter and sterilized at 121°C for 30 minutes; after cooling down, the temperature is controlled at 30°C, and the pH value is adjusted to 5.0 with ammonia water. Inoculate the well-grown seed solution into the tank, and the inoculum amount is 5%. Adjust the...

Embodiment 3

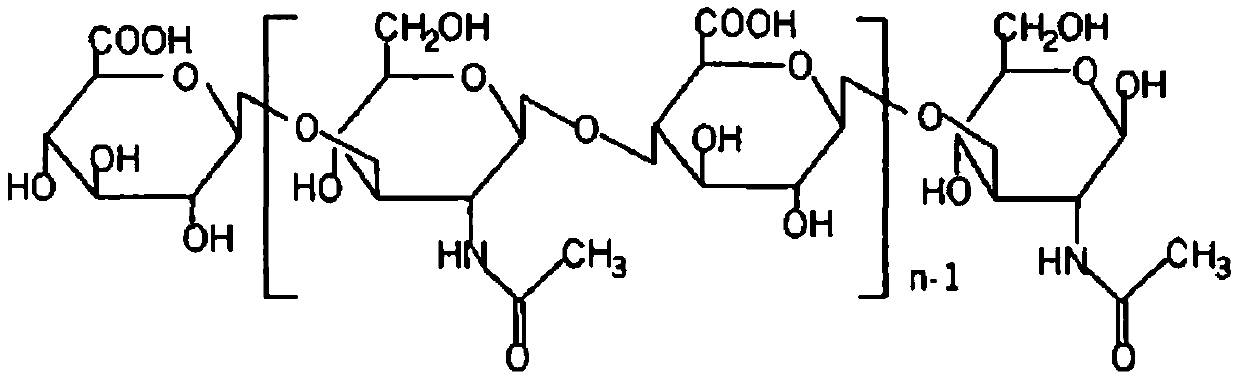

[0077] This example provides a preparation method of oligomeric sodium hyaluronate.

[0078] Add 100L of purified water to a 100L stainless steel dissolution tank, and add a molecular weight of 1.2×10 to the dissolution tank while stirring. 6Da sodium hyaluronate 1kg, after being completely dissolved, adjust the pH to 6.0 with sodium hydroxide, and raise the temperature to 45°C, add 1L of the hyaluronic acid hydrolase prepared in Example 2, use an Ubbelohde viscometer, Use the intrinsic viscosity method to measure the molecular weight of the product in the enzymolysis solution. When the molecular weight of the enzymolysis solution is less than 10000Da, raise the temperature to 65°C and maintain it for 30min. Add 1kg NaCl, filter the enzymolysis solution with a 0.45μm nylon filter, and After membrane filtration and precipitation with 500L ethanol to obtain sodium hyaluronate precipitate, the precipitate was dehydrated with ethanol, and then vacuum-dried to obtain oligomeric sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com