Composite phase-change microcapsule type fluid for high-voltage environment, and preparation method and application thereof

A composite phase change and microcapsule technology, applied in the field of phase change materials, to achieve the effect of improving heat transfer efficiency, facilitating storage, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

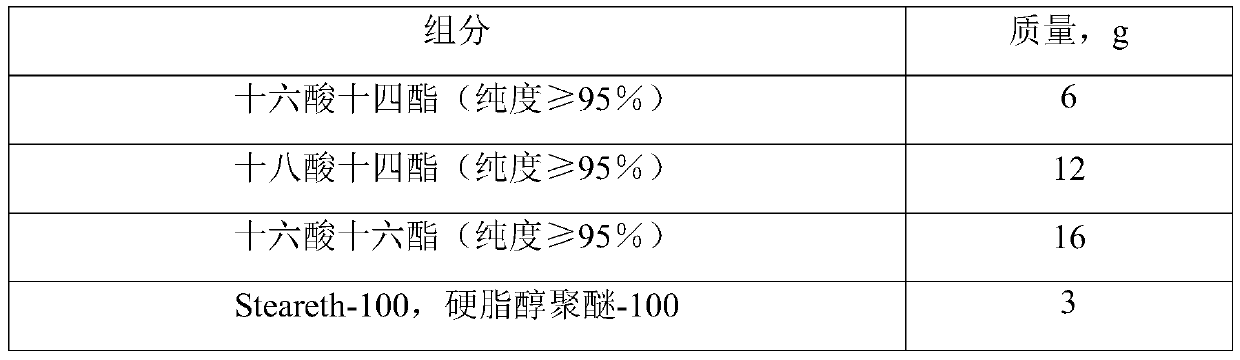

[0045]The preparation of a composite phase-change microcapsule fluid applied in a high-voltage (1kV and above) environment in this embodiment can be used in a direct-contact cold storage device. The raw material formula is shown in Table 1.

[0046] Table 1 Embodiment 1 raw material formula

[0047]

[0048]

[0049] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent) for preparing the core phase change material to 75°C.

[0050] (2) Mix the preheated phase change materials such as myristyl palmitate and other esters, and stir with a stirrer at a low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier with the synthetic Nucleating agents such as steareth-10, steareth-30, steareth-40, steareth-50, steareth-100, steareth-20 , steareth-2, polyvinyl alcohol, oleyl polyoxyethylene ether, magnesium stearate, glycerin, etc. were added to deionized water, and ...

Embodiment 2

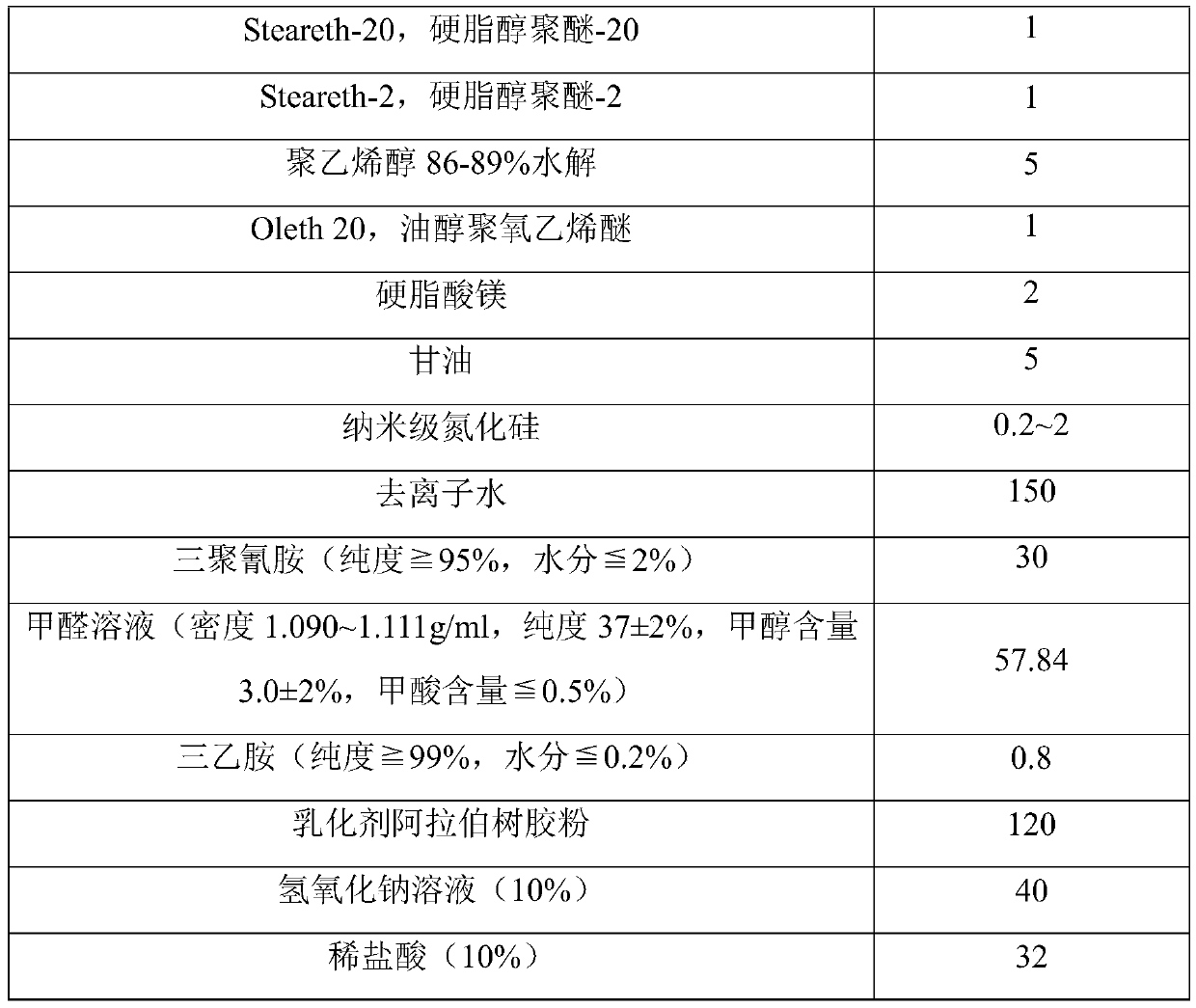

[0057] The preparation of a composite phase-change microcapsule fluid newly applied in a high-voltage (1kV and above) environment in this example can be used in solar photovoltaic photothermal panels. The raw material formula is shown in Table 2.

[0058] Table 2 embodiment 2 raw material formula

[0059]

[0060]

[0061] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent, etc.) for preparing the core phase change material to 75°C.

[0062] (2) Mix the preheated phase change materials such as tridecyl pentadecyl esters, and stir with a stirrer at low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier with the synthetic Nucleating agents such as nonoxynol ether, polyoxyethylene lauryl ether, ceteth-12, polyvinylcyclobutane, magnesium stearate, and glycerin were added to deionized water, and 0.5 g of nano-scale di Molybdenum sulfide and 0.5 g of nanosc...

Embodiment 3

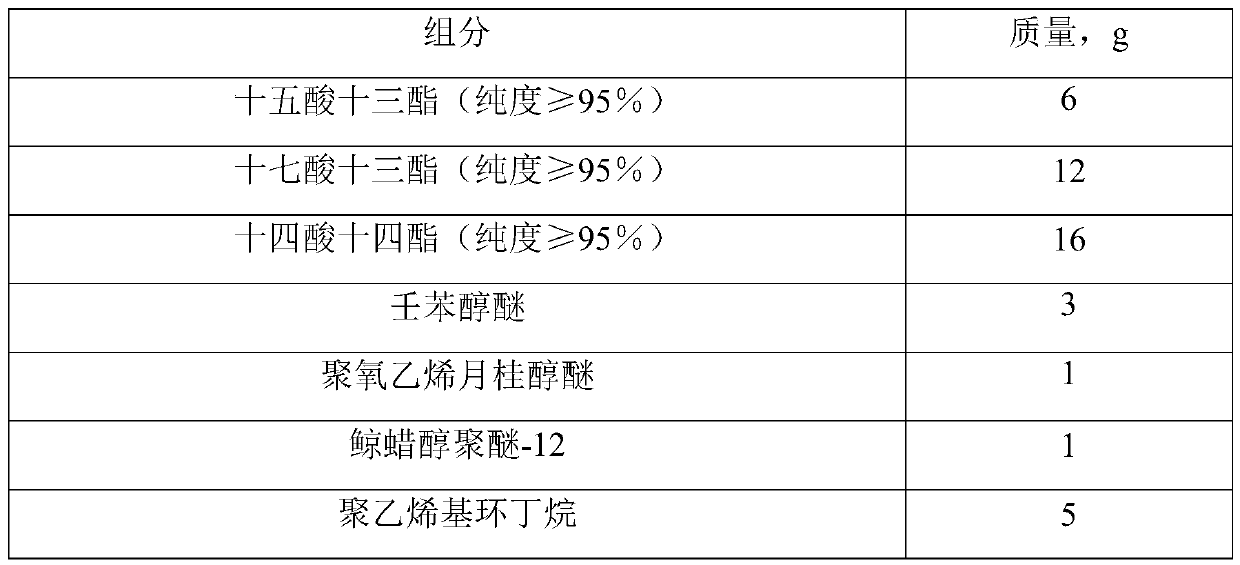

[0069] The preparation of a composite phase-change microcapsule fluid applied in a high-voltage (1kV and above) environment in this embodiment can be used in a circulating cooling system for a diverter valve. The raw material formula is shown in Table 3.

[0070] Table 3 embodiment 3 raw material formula

[0071]

[0072]

[0073] (1) Preheat all the raw materials (deionized water, phase change material, emulsifier and nucleating agent, etc.) for preparing the core phase change material to 75°C.

[0074] (2) Mix the preheated phase change materials such as tridecyl heptadecanoate and other ester acids, and stir with a stirrer at a low speed for 15 minutes to prepare the dispersed phase to obtain the first solution; then mix the preheated emulsifier With nucleating agents such as lauryl heptaglycol ether, cetyl 1,3 propylene glycol ether, oleth-8, polyvinyl-2-methylcyclohexane, poly-3-methyl - 1-butene, polycyclopentene and glycerol were added to deionized water, and 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com