Low-temperature denitration catalyst based on metal organic framework structure and preparation method thereof

A metal-organic framework, denitration catalyst technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of reducing reactive sites, reducing specific surface area, The problem of high production cost, to achieve the effect of good application prospect, large specific surface area and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

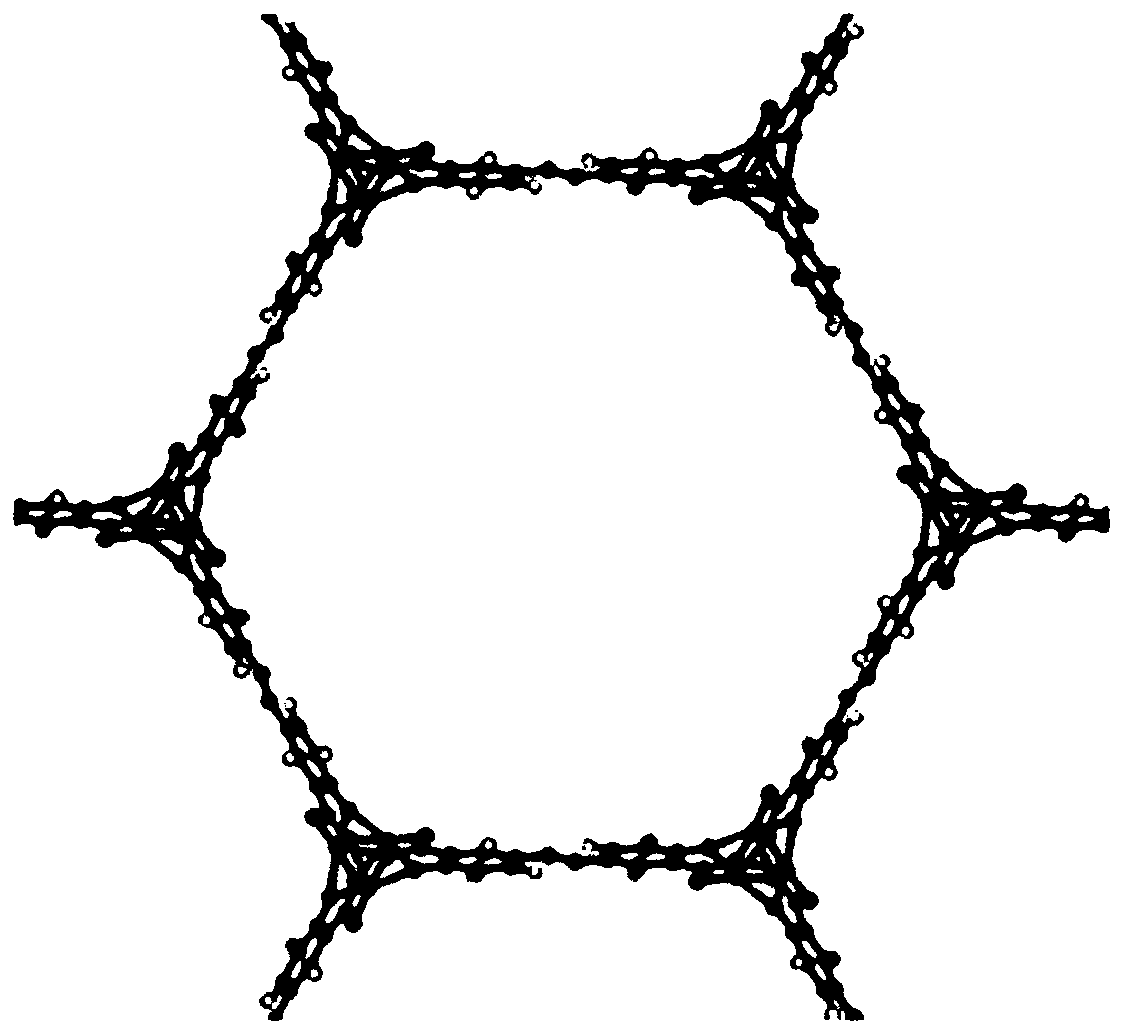

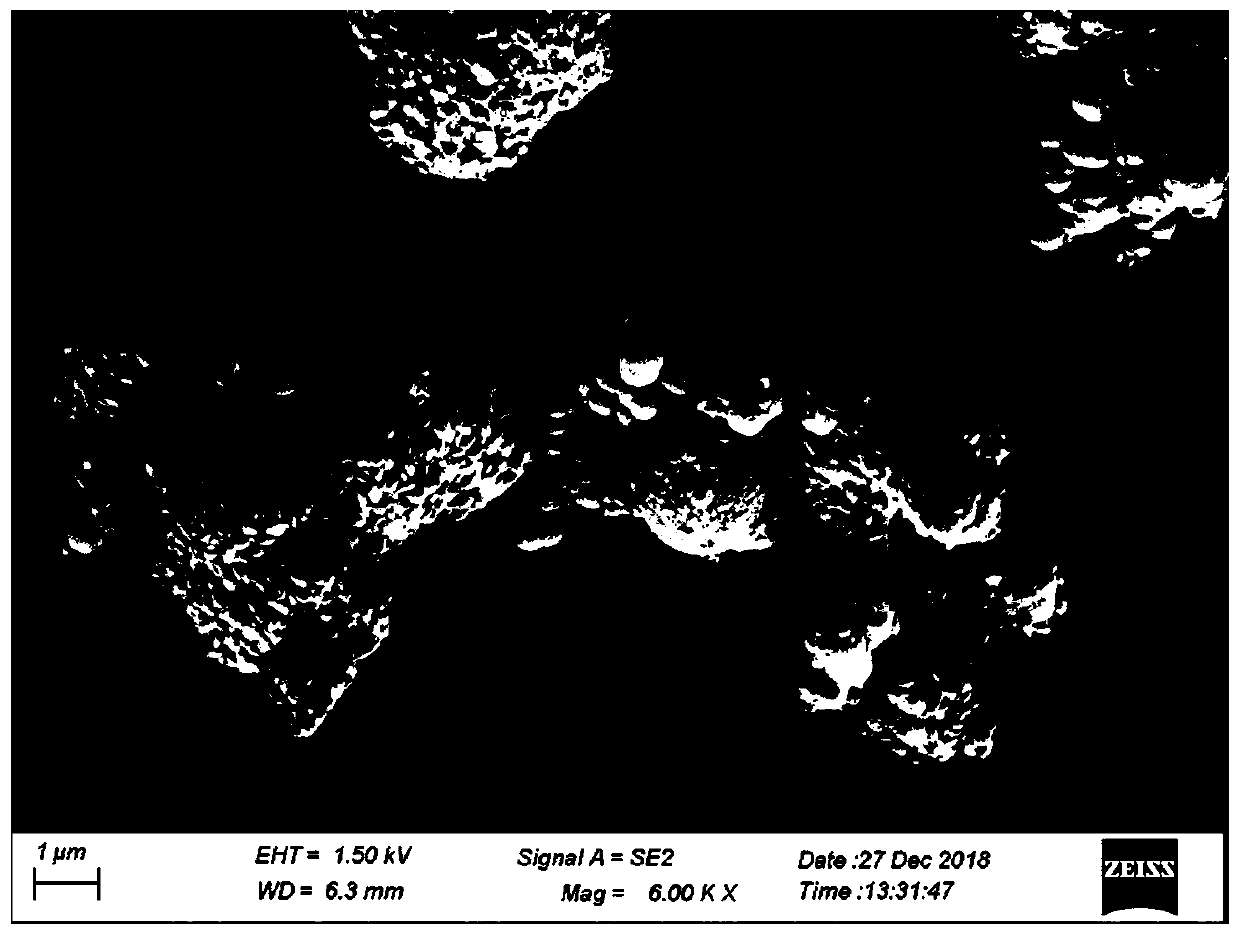

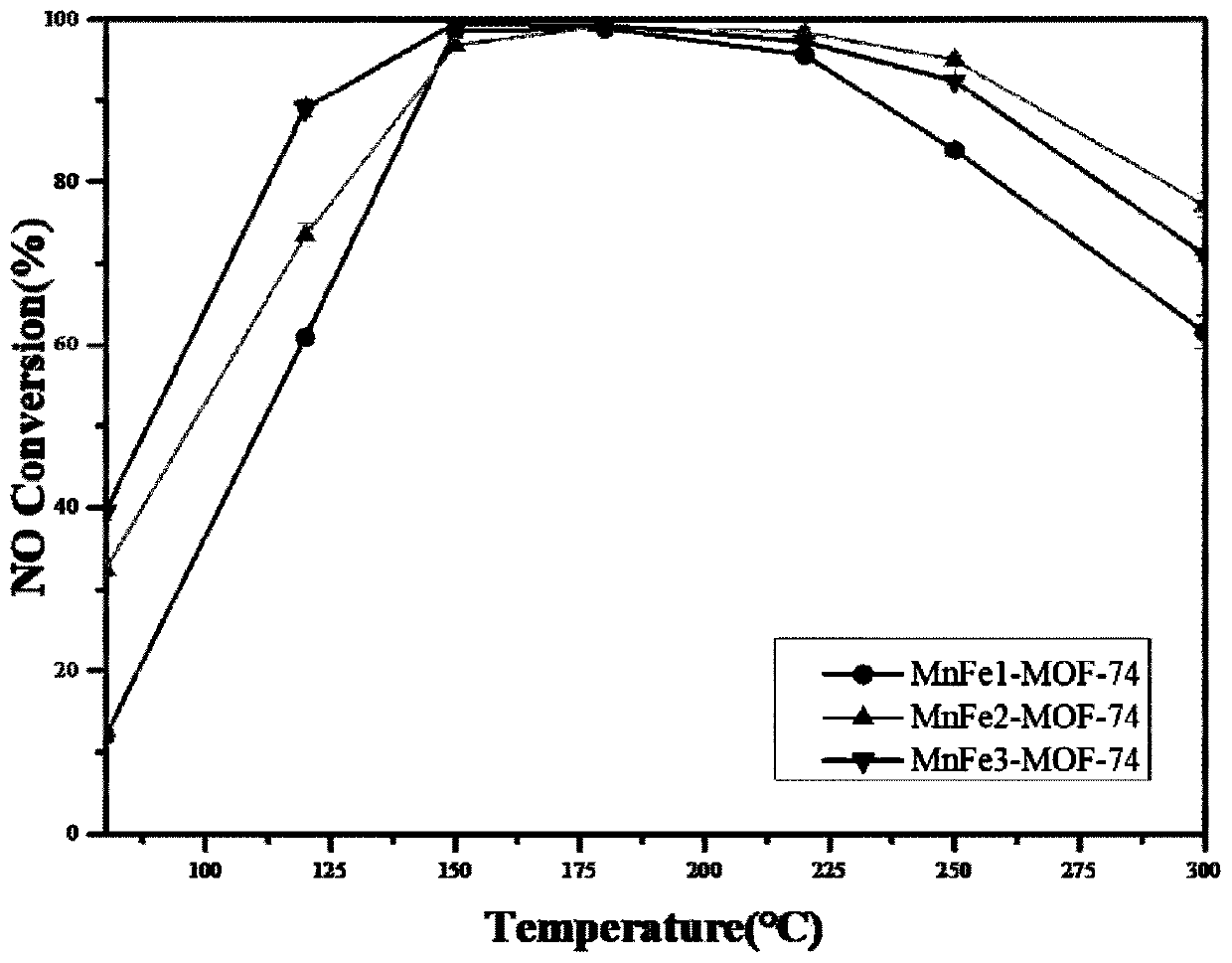

[0029] In this example, a metal-organic framework-based low-temperature denitrification catalyst uses a metal-organic framework MOF-74 as a carrier, and uses metal manganese and metal iron as active components attached to the carrier to form a metal-organic framework- The composite material with MnFe structure is used as a denitrification catalyst for low temperature denitrification at 115-300°C.

[0030] A method for preparing a low-temperature denitration catalyst based on a metal-organic framework structure in this embodiment, comprising the following steps:

[0031] a. According to the solvent mixing ratio, measure 3.5mL of ethanol, 3.5mL of pure water and 53mL of N,N-dimethylformamide (DMF) in a 100mL reaction flask with a graduated cylinder, stir and mix evenly to obtain Mixed solvent;

[0032] b. According to the mixing ratio of the reactants, weigh 0.133g of 2,5-dihydroxyterephthalic acid (DHTP), 0.300g of MnCl 2 4H 2 O, 0.153g of iron nitrate nonahydrate (Fe(NO 3 ...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, especially in that:

[0040] In this example, a metal-organic framework-based low-temperature denitrification catalyst uses a metal-organic framework MOF-74 as a carrier, and uses metal manganese and metal iron as active components attached to the carrier to form a metal-organic framework- The composite material with MnFe structure is used as a denitrification catalyst for low temperature denitrification at 115-300°C.

[0041] A method for preparing a low-temperature denitration catalyst based on a metal-organic framework structure in this embodiment, comprising the following steps:

[0042]a. According to the solvent mixing ratio, measure 3.5mL of ethanol, 3.5mL of pure water and 53mL of N,N-dimethylformamide (DMF) in a 100mL reaction flask with a graduated cylinder, stir and mix evenly to obtain Mixed solvent;

[0043] b. According to the mixing ratio of the reactants, weigh 0.133g of 2,5-dihydroxyterephthalic a...

Embodiment 3

[0050] This embodiment is basically the same as the previous embodiment, and the special features are:

[0051] In this example, a metal-organic framework-based low-temperature denitrification catalyst uses a metal-organic framework MOF-74 as a carrier, and uses metal manganese and metal iron as active components attached to the carrier to form a metal-organic framework- The composite material with MnFe structure is used as a denitrification catalyst for low temperature denitrification at 115-300°C.

[0052] A method for preparing a low-temperature denitration catalyst based on a metal-organic framework structure in this embodiment, comprising the following steps:

[0053] a. According to the solvent mixing ratio, measure 3.5mL of ethanol, 3.5mL of pure water and 53mL of N,N-dimethylformamide (DMF) in a 100mL reaction flask with a graduated cylinder, stir and mix evenly to obtain Mixed solvent;

[0054] b. According to the mixing ratio of the reactants, weigh 0.133g of 2,5-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com