Anti-infection tissue engineering skin scaffold and preparation method thereof

A tissue-engineered skin, anti-infection technology, applied in spinning solution preparation, textile and papermaking, yarn and other directions, can solve the problems of inability to meet structural stability, easy shrinkage deformation, high release concentration, and achieve good cell adhesion and proliferation. Ability, good hydrophilicity and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

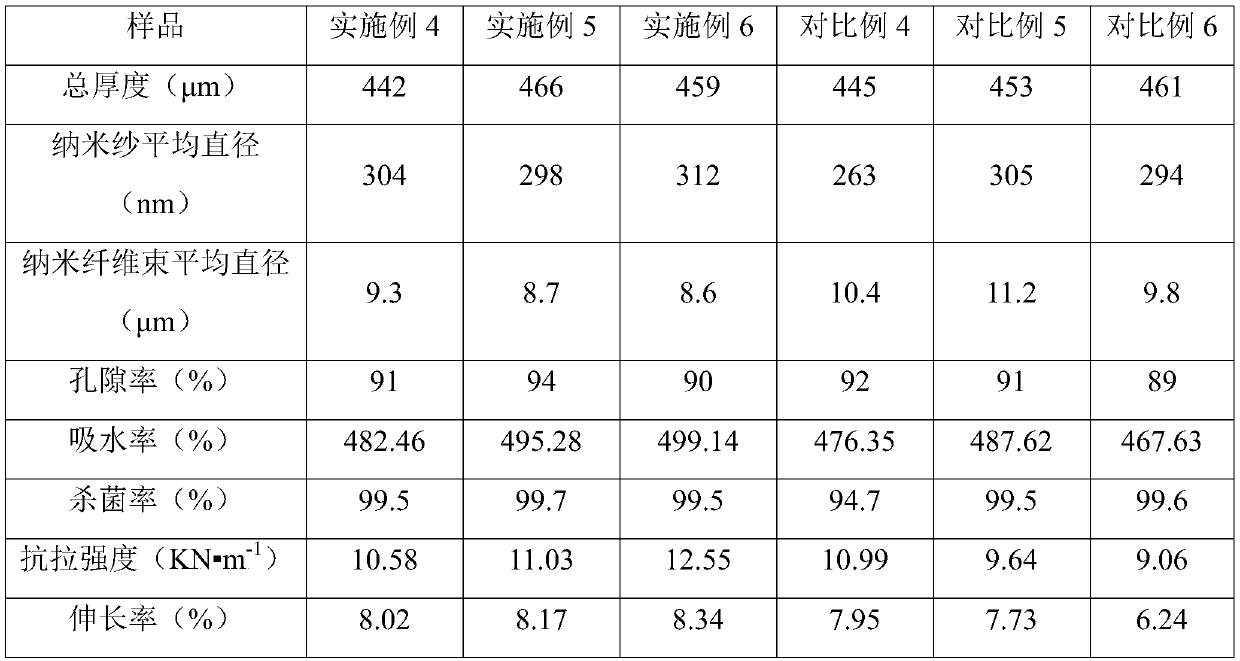

Embodiment 1

[0032] Preparation of polycaprolactone-polyethylene glycol-polycaprolactone / nanometer silver / chitosan nano yarn layer: polycaprolactone-polyethylene glycol-polycaprolactone graft copolymer (purchased from Shanghai Zhenzhun Biotechnology Co., Ltd., article number: ZZR-T-C-2k1k2k) was dissolved in an organic solvent mixed with chloroform and dimethylformamide at a volume ratio of 3:1, stirred by magnetic force until completely dissolved, and then added nanometers with a diameter of 50-100nm Silver, ultrasonically disperse for 30min, let it stand for a while, put it into a 10mL syringe, and eject it from the needle mouth at a high speed under 15kV high-voltage electrostatic traction at a speed of 1mL / h to prepare nanofibers, place a container of water 10cm below the needle tip There are holes in the bottom of the container. After the nanofibers fall to the water surface, they flow down from the holes with the vortex, twist and form nano yarns in bundles, and the rotating shafts re...

Embodiment 2

[0034] Preparation of polycaprolactone-polyethylene glycol-polycaprolactone / nanometer silver / chitosan nano yarn layer: polycaprolactone-polyethylene glycol-polycaprolactone graft copolymer (purchased from Shanghai Zhenzhun Biotechnology Co., Ltd., article number: ZZR-T-C-2k1k2k) was dissolved in an organic solvent mixed with chloroform and dimethylformamide at a volume ratio of 3:1, stirred by magnetic force until completely dissolved, and then added nanometers with a diameter of 50-100nm Silver, ultrasonically disperse for 30 minutes, let it stand for a while, put it into a 10mL syringe, and eject it from the needle mouth at a high speed under 15kV high-voltage electrostatic traction at a speed of 1mL / h to prepare nanofibers. Place a container of water 12cm below the needle tip There are holes in the bottom of the container. After the nanofibers fall to the water surface, they flow down from the holes with the vortex, twist and form nano yarns in bundles, and the rotating shaf...

Embodiment 3

[0036] Preparation of polycaprolactone-polyethylene glycol-polycaprolactone / nanometer silver / chitosan nano yarn layer: polycaprolactone-polyethylene glycol-polycaprolactone graft copolymer (purchased from Shanghai Zhenzhun Biotechnology Co., Ltd., article number: ZZR-T-C-2k1k2k) was dissolved in an organic solvent mixed with chloroform and dimethylformamide at a volume ratio of 3:1, stirred by magnetic force until completely dissolved, and then added nanometers with a diameter of 50-100nm Silver, ultrasonically disperse for 30 minutes, let it stand for a while, put it into a 10mL syringe, and eject it from the needle mouth at a high speed under 15kV high-voltage electrostatic traction at a speed of 1mL / h to prepare nanofibers. Place a container of water 12cm below the needle tip There are holes in the bottom of the container. After the nanofibers fall to the water surface, they flow down from the holes with the vortex, twist and form nano yarns in bundles, and the rotating shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com