Ammonia nitrogen efficient removal system and ammonia nitrogen efficient removal method based on side flow short-cut nitrification-anaerobic ammonia oxidation process

An anaerobic ammonia oxidation and short-range nitrification technology, which is applied in the field of high-efficiency ammonia nitrogen removal systems, can solve the problems of difficulty in providing suitable temperature, unstable removal efficiency, and inability to reuse regenerated liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

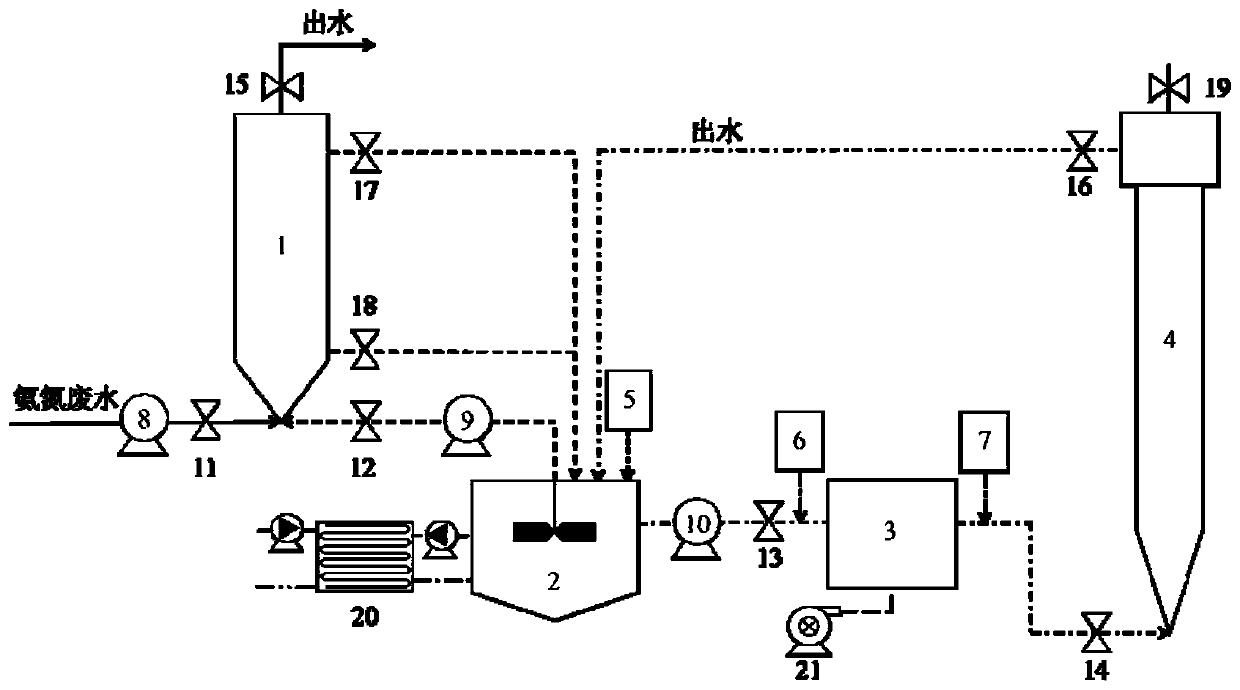

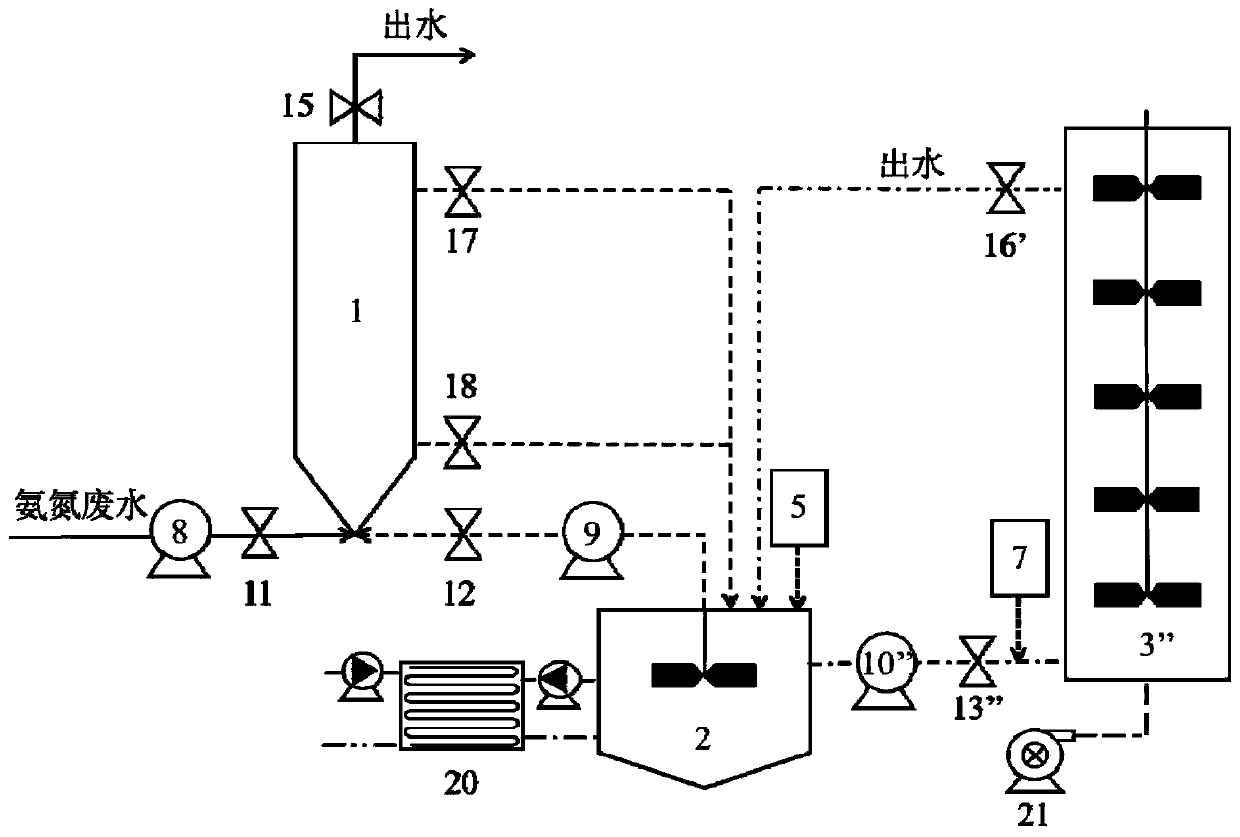

[0111] A high-efficiency ammonia nitrogen removal system based on short-range nitrification-anammox process, the flow chart is as follows figure 1 As shown, it includes ammonia nitrogen adsorption unit, heating regeneration unit, partial nitrosation unit and ANAMMOX denitrification unit. The ammonia nitrogen adsorption unit includes a sewage inlet pump 8 , a water inlet valve 11 , an ammonia nitrogen adsorption column 1 filled with adsorption materials, and an ammonia nitrogen adsorption column drain valve 15 connected in sequence.

[0112] The heating regeneration unit includes a regeneration liquid storage tank 2, the regeneration liquid storage tank 2 is connected to the ammonia nitrogen adsorption column 1 through a pipeline, and a regeneration liquid inlet pump 9 and a regeneration liquid inlet valve 12 are sequentially arranged on the connecting pipe between the two, and the regeneration liquid The storage tank 2 is equipped with regeneration liquid, and the regeneration...

Embodiment 2

[0117] For the sewage of a sewage treatment plant with an ammonia nitrogen concentration of 25mg / L, it needs to be treated to meet the requirements of GB18918-2002 Class A standard (5mg / L). The above-mentioned system is used for pilot test research, and the water treatment volume of the pilot test is 2.2 tons / day.

[0118] The sewage enters the ammonia nitrogen adsorption column 1 through the sewage inlet pump 8 through the water inlet valve 11. The ammonia nitrogen adsorption column 1 has a volume of 1L and is filled with natural zeolite. The hydraulic retention time is 5min, the adsorption operation time is 4h, the water volume that can be treated in one operation is 48L, the water volume that can be treated per hour is 12L / h, and the water volume that can be treated per day is 264L / d (calculated according to 22h), and 8 groups of ammonia nitrogen adsorption columns are connected in parallel Running, 2 sets of ammonia nitrogen adsorption columns for standby. After reaching ...

Embodiment 3

[0121] For the tail water of a sewage treatment plant with an ammonia nitrogen concentration of 15mg / L, it needs to be treated to meet the requirements of GB18918-2002 Class A Standard (5mg / L). The side-stream SHARON-ANAMMOX system is used for pilot-scale research, and the pilot-scale treatment water volume is 2.5 tons / day.

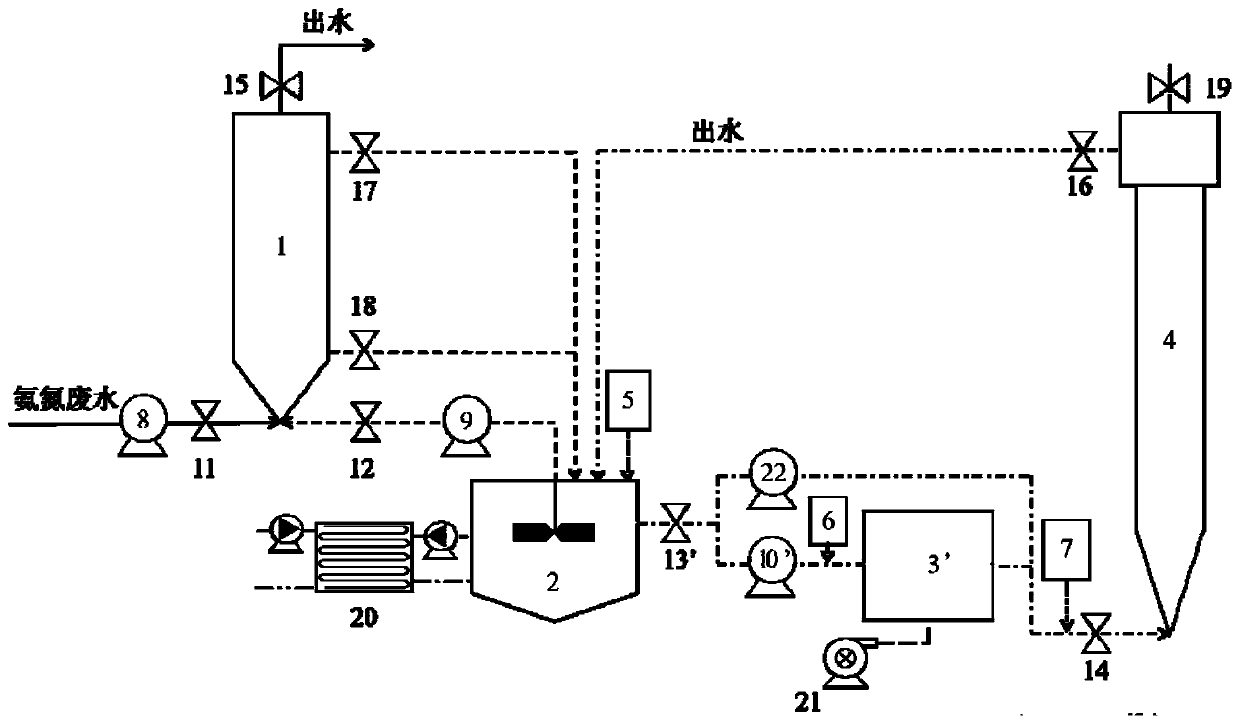

[0122] This embodiment is roughly the same as Embodiment 1, except that the regeneration solution denitrification module is a short-range nitrification-anammox unit composed of a short-range nitrification unit and anammox unit. Such as figure 2 Shown:

[0123] The short-path nitrification unit includes a short-path nitrification reactor 3', which is connected to the regeneration liquid storage tank 2 through a pipeline, and a short-path nitrification water inlet pump 10' and a first pH regulator 6 are provided on the connecting pipeline between the two. , the short-path nitrification reactor 3' is connected to the aeration pump 21, the water outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com