Copper-doped quasi-two-dimensional all-inorganic perovskite material and preparation method thereof

A technology of copper doping and inorganic calcium, applied in the direction of luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity of perovskite thin films and achieve optical performance improvement and efficiency Effects of Lifting, Quantum Yield, and Nanocrystal Lifetime Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]Example 1CU0.6-CSPB0.4CL3Preparation

[0064](1) 0.4g CS2CO320 ml of octadene and 1.5 ml oleic acid were added to the three-neck flask, and then heated to 120 ° C under vacuum, then the AR reaction was 1 h, resulting in a precursor;

[0065](2) 0.08g Cucl21 ml olelamine and 5 mL of octadene were added to the three-neck flask, heated to 100 ° C under AR protection;

[0066](3) 0.08g Cucl20.114G PBCL2In the formation of 10 ml of octadene, it was heated to 120 ° C under vacuum, and 1 ml of oleic acid and 1 ml of olelamine were added, and then the AR reaction was transferred for 10 minutes and 1 ml of triamatyl phosphorus (TOP), Then continue to react 50 min. Then, the precursor was added to 200 ° C, and the precursor was prepared in 1 ml of step (1) was added, and the reaction was 1min, and then cooled to room temperature with ice water;

[0067](4) Cu-CSPBCL obtained by step (3)3Cucl obtained in solution and step (2)2The solution was mixed, the temperature was set to 100 ° C, the stirring t...

Embodiment 2

[0069]Example 2CU0.6-CSPB0.4(CL / BR)3Preparation

[0070](1) 0.4g CS2CO320 ml of octadene and 1.5 ml oleic acid were added to the three-neck flask, and then heated to 120 ° C under vacuum, then the AR reaction was 1 h, resulting in a precursor;

[0071](2) 0.08g Cucl21 ml olelamine and 5 mL of octadene were added to the three-neck flask, heated to 100 ° C under AR protection;

[0072](3) 0.08g Cucl20.114G PBCL2In the formation of 10 ml of octadene, it was heated to 120 ° C under vacuum, and 1 ml of oleic acid and 1 ml of olelamine were added, and then the AR reaction was transferred for 10 minutes and 1 ml of triamatyl phosphorus (TOP), Then continue to react 50 min. Then, the precursor was added to 200 ° C, and the precursor was prepared in 1 ml of step (1) was added, and the reaction was 1min, and then cooled to room temperature with ice water;

[0073](4) Cu-CSPBCL obtained by step (3)3Cucl obtained in solution and step (2)2The solution was mixed, the temperature was set to 100 ° C, the sti...

experiment example 1

[0076]Experimental Example 1 Structure Characterization of Copper Doped Oterocate Infrastructant Calcanotium Mine

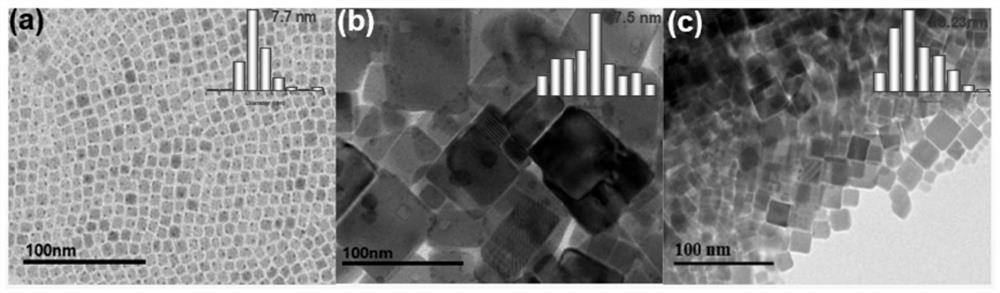

[0077]The purple light Cu prepared in Example 1 and Example 2 was prepared by Fei Tecnai G2 F20 S-TEM.0.6-CSPB0.4CL3Blu-ray Cu0.6-CSPB0.4(Br / cl)3The morphology structure and two-dimensional size are characterized.figure 1 Indicated.

[0078]Fromfigure 1 Can be learned infigure 1 Medium (a) undoped CSPBCL3Still has a traditional quantum point in shape, with an average particle size of 7.7 nm. Further, the present invention has been prepared by two step passivation, Cu-CSPBCl3The micro-morphology of the two-dimensional nanoflake is present, with an average particle diameter of 47.5 nm. After the anion exchange, although prepared Cu-CSPB (BR / CL)3The size of the blue nano sheet is slightly reduced (the average particle size is 19.23 nm), but still maintains the morphology of the two-dimensional nanofile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com