Alkaline polishing solution for reducing CMP defects of multi-layer copper interconnection barrier layer and preparation method of alkaline polishing solution

A technology of barrier layer and copper interconnection, applied in the field of polishing liquid, can solve the problems of lower yield, reliability failure, device failure, etc., and achieve the effects of simple composition, good stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

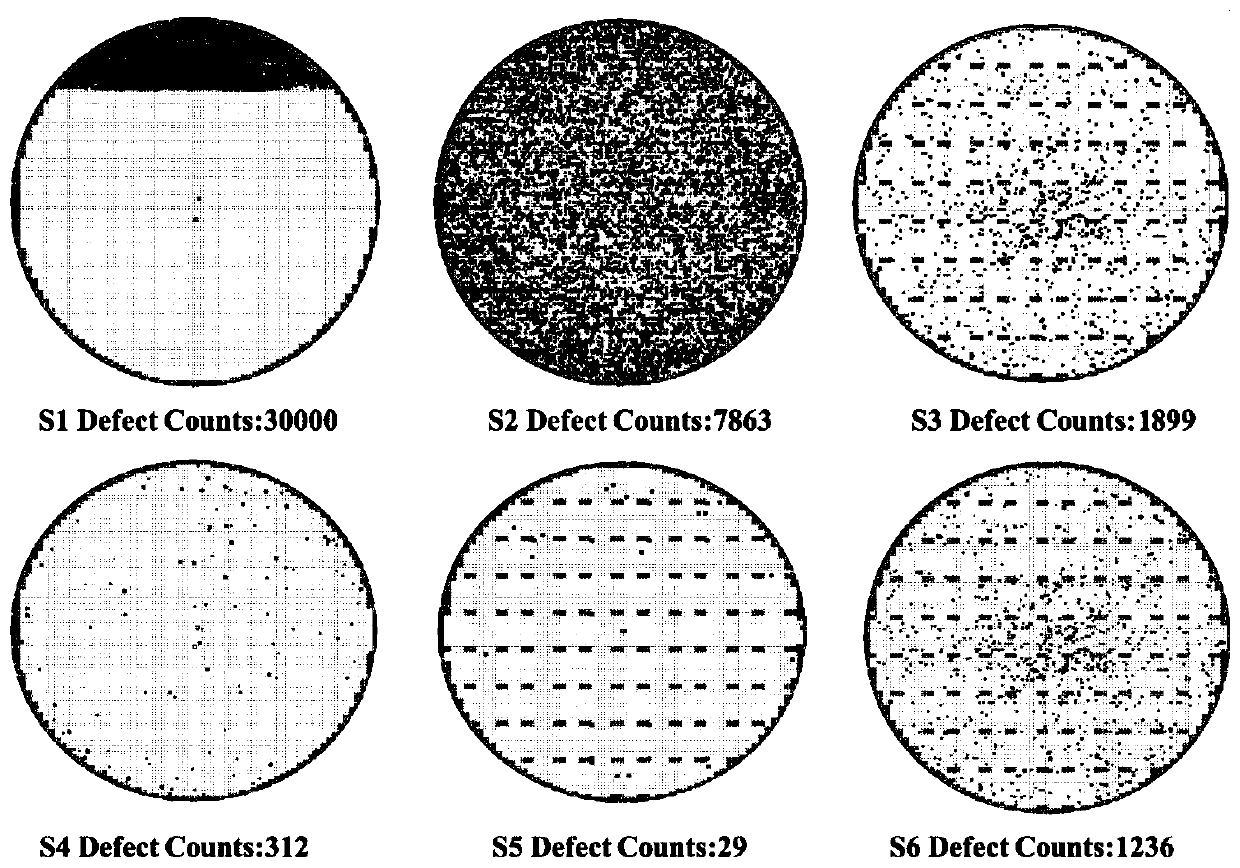

[0033] Embodiment one (Sample 1, S1) does not contain surfactant:

[0034] Take 250g of abrasive mass fraction 40% silica sol, its particle size is 50nm-90nm, and its dispersion is between ± 3%; 10g of FA / OII chelating agent is used as a pH regulator, buffer and chelating agent, and does not contain metal ions; Hydrogen peroxide 0.05g. The specific preparation method is as follows: Add FA / O II chelating agent, hydrogen peroxide and silica sol in sequence according to the component weight into appropriate amount of deionized water, stir evenly through step-by-step mixing, and finally make up to 1000g with deionized water, continue stirring evenly Can.

[0035] Test monitoring: the pH of the polishing solution is 9.5, and the particle size is 80-120nm.

[0036] Defect test experiment: use the prepared polishing liquid on the AMAT-LK CMP polishing machine produced by Applied Materials; the working pressure is Z 1 : 1psi, Z 2 : 1.7psi, Z 3 : 1.5psi, Z 4 : 1.5psi, Z 5 : 1.5p...

Embodiment 2

[0037] Embodiment two (Sample 2, S2) surfactant only contains nonionic active agent:

[0038] Take 250g of abrasive mass fraction 40% silica sol, its particle size is 50nm-90nm, and its dispersion is between ± 3%; 10g of FA / OII chelating agent is used as a pH regulator, buffer and chelating agent, and does not contain metal ions; Take 0.1g, 0.5g, 1g, 1.5g, 3g of dodecyldimethylamine oxide and 0.05g of hydrogen peroxide respectively. The specific preparation method is as follows: FA / O II chelating agent, dodecyl dimethyl amine oxide (OA), hydrogen peroxide and silica sol are sequentially added into appropriate amount of deionized water according to the component weight, stirred evenly by stepwise mixing, and finally Make up to 1000g with deionized water, and continue to stir evenly. Test monitoring: the polishing liquid has a pH of 9.5 and a particle size of 80-110 nm.

[0039] Defect test experiment: use the prepared polishing liquid on the AMAT-LK CMP polishing machine prod...

Embodiment 3

[0040] Embodiment three (Sample 3, S3) surfactant is the composite of anionic active agent and nonionic active agent, and the mass ratio of anionic active agent and nonionic active agent is 0.1-3:1, and surfactant is in polishing The mass percentage in the liquid is 0.11-0.4%.

[0041] Take 250g of abrasive mass fraction 40% silica sol, its particle size is 50nm-90nm, and its dispersion is between ± 3%; 10g of FA / OII chelating agent is used as a pH regulator, buffer and chelating agent, and does not contain metal ions; Take 0.1g, 0.5g, 1g, 1.5g, 3g of ammonium lauryl sulfate, 1g of lauryl dimethylamine oxide, and 0.05g of hydrogen peroxide. The specific preparation method is as follows: add FA / O II chelating agent, lauryl ammonium sulfate, lauryl dimethyl amine oxide, hydrogen peroxide and silica sol into an appropriate amount of deionized water in sequence according to the component weight, and mix step by step Stir evenly, and finally make up to 1000g with deionized water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com