Liquid metal aerogel as well as preparation method and application thereof

A liquid metal and aerogel technology, applied in the field of nanomaterials, can solve the problems of lack of precursors in liquid metals, large surface tension of liquid metals, and difficulty in synthesizing macroscopic materials, achieving good hydrophilicity and chemical stability, excellent Effects of photothermal and strong sunlight absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

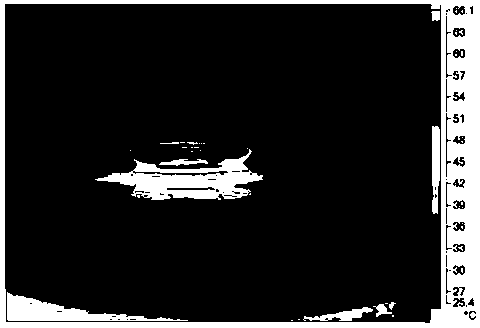

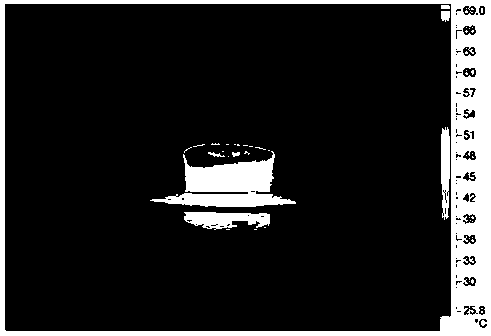

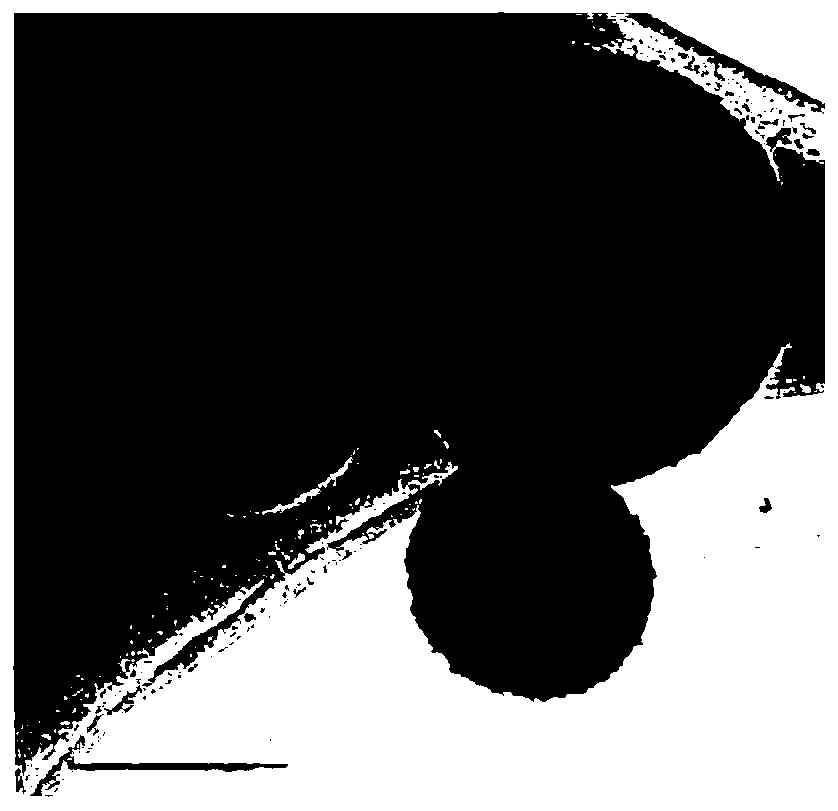

Image

Examples

preparation example Construction

[0049] Another aspect of the embodiments of the present invention also provides a method for preparing a liquid metal aerogel, comprising the following steps:

[0050] (1) dispersing the liquid metal in an aqueous polysaccharide solution to form liquid metal nanoparticles, and wrapping the liquid metal nanoparticles by polysaccharides to obtain a stable dispersion;

[0051] (2) Uniformly mix the dispersion of liquid metal nanoparticles obtained in step (1) with graphene oxide, then sequentially add metal hydroxide colloid and gluconolactone for ionic cross-linking, and let stand to obtain liquid metal hydrogel glue;

[0052] (3) reducing the graphene oxide in the liquid metal hydrogel with a reducing agent;

[0053] (4) Solvent replacement and drying are performed on the liquid metal hydrogel obtained in step (3) to obtain the liquid metal aerogel.

[0054] In some more specific embodiments, the preparation method specifically includes:

[0055] (1) Ultrasonic dispersion of...

Embodiment 1

[0087] (1) Preparation of liquid metal nanoparticles: prepare a sodium alginate aqueous solution with a mass percentage of 0.01wt%, take 40mL, add 40mg of liquid metal gallium, and use 400W power for ultrasonication to obtain a dispersion of gallium nanoparticles, which is wrapped in liquid metal The thickness of sodium alginate on the gallium surface is 5nm.

[0088] (2) Mix 4 mL of the above-mentioned gallium nanoparticle dispersion with 2 mL of 4 mg / mL graphene oxide aqueous solution, mix well, add 0.1 mol of lanthanum hydroxide colloidal solution, then add 2 mol of gluconolactone, stir for 30 s and let stand for 12 h, A liquid metal gallium hydrogel is obtained.

[0089] (3) The liquid metal hydrogel was immersed in a 1.5 mol / L ascorbic acid aqueous solution for 48 hours at room temperature to reduce the graphene oxide.

[0090] (4) Replace the above-mentioned liquid gallium metal hydrogel with ethanol, the volume ratio of ethanol and liquid metal gallium hydrogel is 5:1,...

Embodiment 2

[0093](1) Preparation of liquid metal nanoparticles: Prepare a chitin solution with a mass percentage of 1wt%, take 40mL, add 40mg of liquid metal indium, and use 400W power for ultrasonication to obtain an indium nanoparticle dispersion, which is wrapped on the surface of the liquid metal indium The thickness of sodium alginate is 8nm.

[0094] (2) Take 4mL of the above-mentioned indium nanoparticle dispersion and mix with 2mL of 4mg / mL graphene oxide aqueous solution. After mixing evenly, add 1mol ferric hydroxide colloidal solution, then add 0.1mol gluconolactone, stir for 30s and then let it stand for 12h. A liquid metal indium hydrogel is obtained.

[0095] (3) The above-mentioned liquid metal indium hydrogel was immersed in a 3 mol / L ascorbic acid aqueous solution, and immersed at 40° C. for 40 h to reduce the graphene oxide.

[0096] (4) Replace the above-mentioned liquid metal indium hydrogel with ethanol, the volume ratio of ethanol to liquid metal indium hydrogel is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com