Titanium and titanium alloy-glass material for Kovar sealing and its preparation method and application

A glass material and sealing glass technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve problems such as easy high temperature oxidation, difficult sealing, poor wettability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing titanium and titanium alloy-Kovar sealing glass powder, comprising the following steps:

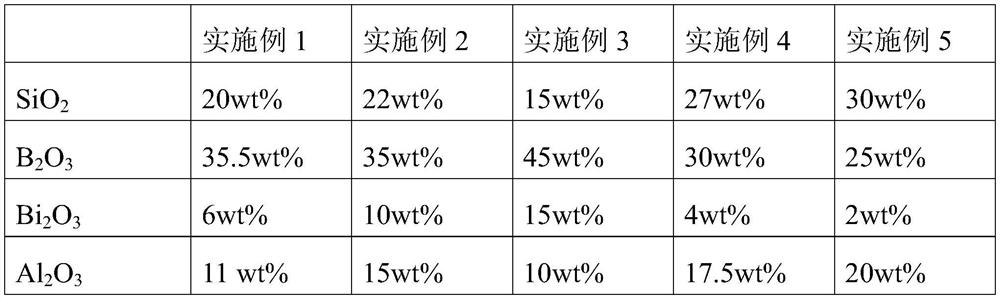

[0031] Step 1), by mass percentage, get following raw material: SiO 2 : 15-30%, B 2 o 3 : 25~45%, Bi 2 o 3 : 2~15%, Al 2 o 3 : 10-20%, Na 2 O: 0.5~7.5%, K 2 O: 0.5-7.5%, MgO: 0.5-10%, CaO: 0.5-10%, SrO: 0.5-10%, BaO: 0.1-2.5%, Sb 2 o 3 : 0.5~1.5%, CuO: 0.1~1.5%;

[0032] Step 2), after mixing all the raw materials evenly, heat and melt in a high temperature furnace until the glass liquid is clarified; quenching the glass liquid with deionized water quenching method to obtain glass fragments;

[0033] Specifically, the raw materials are placed in a planetary ball mill for ball milling, so that the ingredients are mixed evenly; the grinding speed is 280-320r / min, and the grinding time is 30-60min; the mixed materials are placed in a crucible, and the crucible is placed in In the high-temperature lifting furnace, the glass liquid is obtained after heati...

Embodiment 1

[0053] A preparation method of titanium and titanium alloy and Kovar alloy sealing glass material for thermal battery, specifically comprising the following steps:

[0054] Step 1), select chemical composition batching by following weight percentage:

[0055] SiO 2 : 20%, B 2 o 3 : 35.5%, Bi 2 o 3 : 6%, Al 2 o 3 : 11%, Na 2 O: 4%, K 2 O: 4%, MgO: 3%, CaO: 4%, SrO: 10%, BaO: 1.9%, Sb 2 o 3 : 0.5%, CuO: 0.1%;

[0056] Step 2) Put the raw materials of the above-mentioned components in a ball mill for ball milling, so that the ingredients are mixed evenly, the grinding speed is 300r / min, and the time is 30min;

[0057] Step 3) Put the ball-milled and mixed materials in step 2) in a corundum crucible or a platinum crucible, place the crucible in a high-temperature lifting furnace, and raise the temperature to 700°C at a heating rate of 10°C / min in an air atmosphere and keep it warm for 40min. Then increase the temperature at a rate of 10°C / min to 1350°C and keep it warm...

Embodiment 2

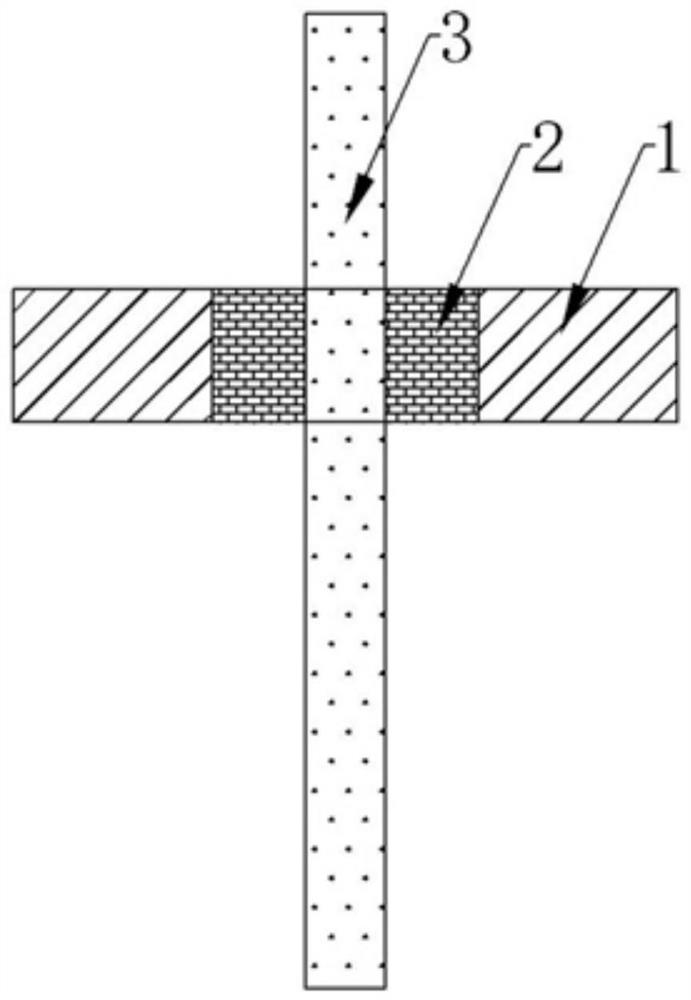

[0078] Embodiment 2 The specific sealing method process: the metal shell 1 is pre-oxidized at 500°C for 20 minutes, the metal conductor stem 3 is pre-oxidized at 500°C for 15 minutes, and then the metal shell 1 and the glass body 2 set in the through hole of the metal shell are sealed. And the metal conductor core column 3 is loaded into the sintering mold according to the corresponding order, put the semi-finished components together with the sintering mold into the high-temperature sintering furnace, pass in nitrogen as a protective gas, heat up to 750 ° C according to a certain program, and keep it for 30 minutes for sintering to soften Or a good tight seal is formed between the glass body in the molten state, the metal conductor core post and the metal shell, and annealed for 15 minutes when the temperature is lowered to 500 ° C, and then lowered to room temperature, so as to obtain a titanium-glass seal with excellent performance for aerospace connectors. connect component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com