Method for preparing crystal form thioamino carboxylate by taking secondary amine as raw material

A technology of thioaminocarboxylate and crystal form, which is applied in the field of preparation of fine chemicals, can solve problems affecting the speed and degree of reaction, complicated post-processing, and affecting purity, so as to improve the reaction activity and product purity , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

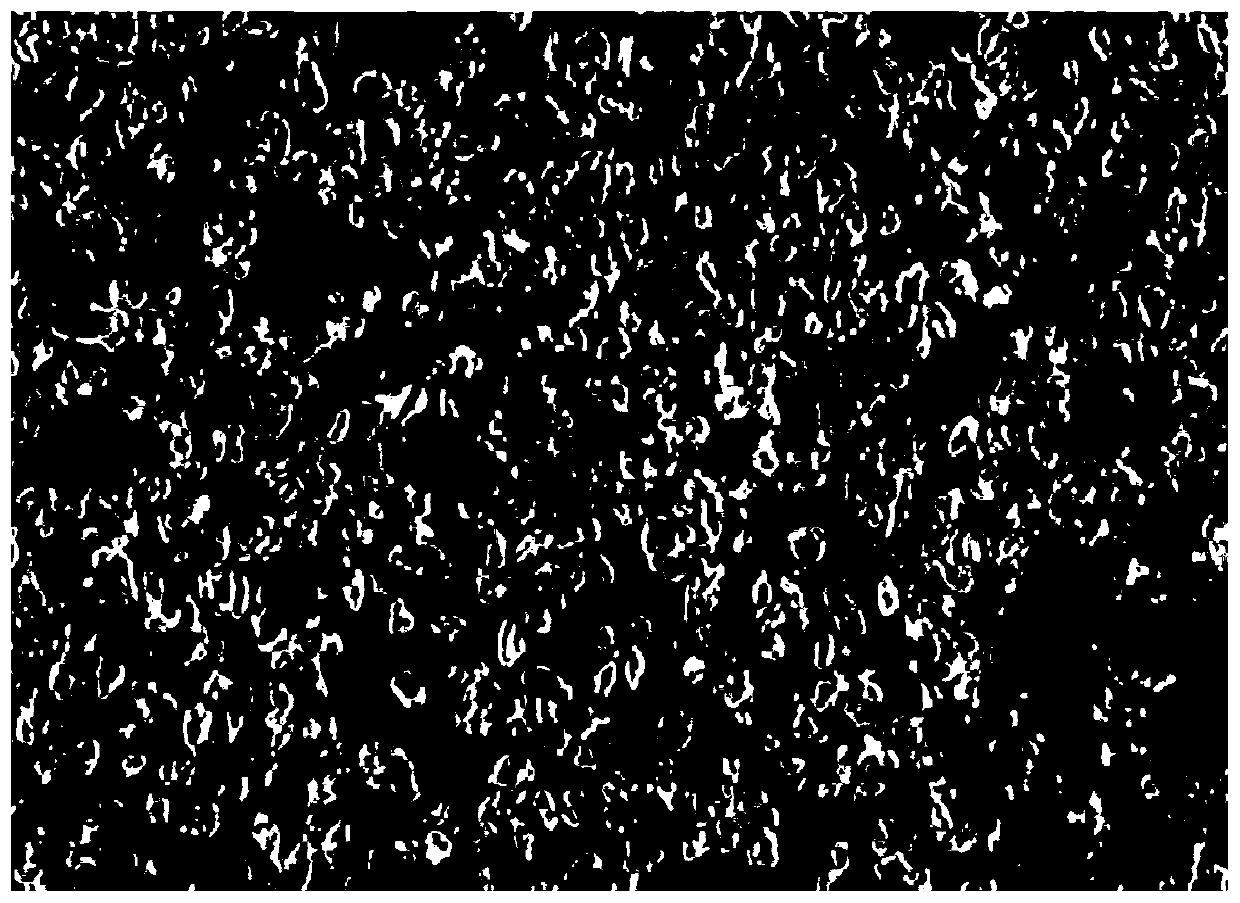

[0036] At room temperature, to 1m 3 Add 400kg of water, 34kg of nanometer zinc oxide (average particle size of electron microscope is 57nm), 0.68kg of RP-90 into the reactor, and mix well. Continue to add 32.5kg of carbon disulfide, and slowly add 45.0Kg of dimethylamine aqueous solution (40%); after the addition, add 32.5kg of carbon disulfide again, and add dropwise 45.0Kg of dimethylamine aqueous solution (40%). Gradually raise the temperature and react to weak reflux, and the reaction ends in 5.5 hours. separate. Obtaining white crystals is zinc dimethyl dithioaminocarboxylate, and the product is finely divided crystals, and its crystal form is shown in the attached figure 1 . The dry product has a yield of 99.3% based on amine and a purity of 99.3%. The ammonia nitrogen in the mother liquor is 17mg / L, and the chemical oxygen demand is 180mg / L.

Embodiment 2

[0038] At room temperature, to 1m 3 Add 400kg of water, 43.0kg of zinc hydroxide (D50=8.94μm), and 0.05kg of RP-90 into the reactor, and mix well. Continue to add 30.0kg of carbon disulfide, and slowly add 30.0Kg of dimethylamine aqueous solution (40%); repeat this way for a total of three times until the addition is complete. Gradually raise the temperature and react to weak reflux, and the reaction ends in 3 hours. separate. The white crystal obtained is zinc dimethyl dithioaminocarboxylate. The dry product has a yield of 99.0% based on amine and a purity of 99.5%.

Embodiment 3

[0040] At room temperature, to 1m 3 Add 400kg of water, 32.5kg of ground industrial zinc oxide (D90=2.8μm), and 2.2kg of FMES into the reactor, and mix well. Continue to add 120.0kg of carbon disulfide, and slowly add 90.0Kg of dimethylamine aqueous solution (40%). Gradually raise the temperature and react to weak reflux, and the reaction ends in 6 hours. separate. The white crystal obtained is zinc dimethyl dithioaminocarboxylate. The dry product has a yield of 98.6% based on amine and a purity of 99.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com