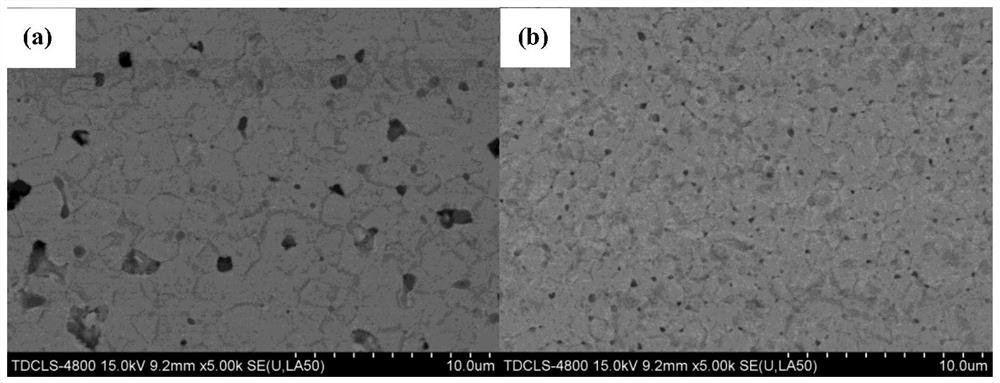

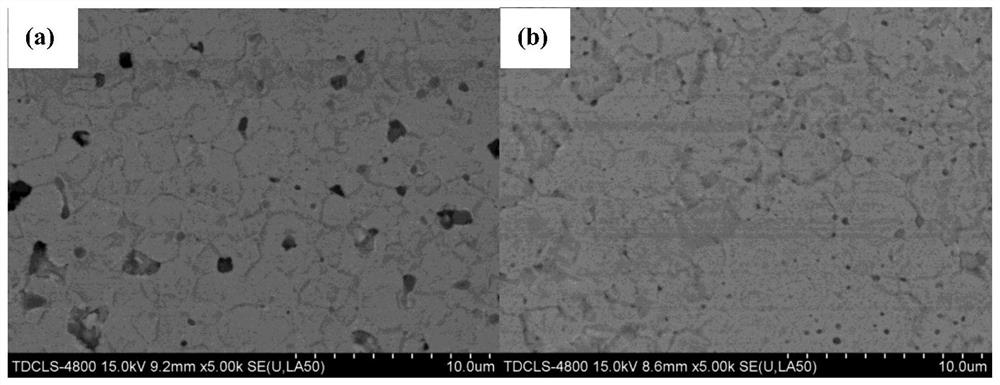

A method for refining the size of yttrium oxide at grain boundaries in yttrium oxide dispersion-strengthened tungsten-based alloys

A technology of dispersion strengthening and yttrium oxide, applied in the field of powder metallurgy, can solve the problems of weakening of the second phase interface, cracking of the second phase particles, deterioration of the mechanical properties of the alloy, etc., so as to improve the comprehensive mechanical properties, processing performance and distribution uniformity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 0.257g of yttrium nitrate hexahydrate and 0.04g of lanthanum nitrate hexahydrate in 120mL of deionized water, stir them with mechanical stirring to fully disperse and dissolve them, and then add 20g of ammonium paratungstate (APT) into it (concentration of ammonium paratungstate in the solution is 0.17g / mL; the quality of yttrium nitrate hexahydrate is 0.0129 times of the quality of ammonium paratungstate; the quality of lanthanum nitrate hexahydrate is 0.154 times of the quality of yttrium nitrate hexahydrate);

[0028] (2) Add 15 mL of concentrated HNO with a concentration of 65% to 68% 3 Add it to the above solution, and under the action of mechanical stirring, the chemical precipitation reaction is uniformly carried out for 30 minutes until a suspension is formed (the volume ratio of nitric acid to deionized water is 1 / 8);

[0029] (3) Add 135 mL of absolute ethanol to the suspension and continue to react for 3 hours. During the entire reaction, the mec...

Embodiment 2

[0034] (1) Dissolve 0.741g of yttrium nitrate hexahydrate and 0.148g of hafnium oxychloride in 120mL of deionized water, stir them with mechanical stirring to fully disperse and dissolve them, and then add 30g of ammonium paratungstate (APT) into it (the concentration of ammonium paratungstate in the solution is 0.25g / mL; the quality of yttrium nitrate hexahydrate is 0.0247 times of the quality of ammonium paratungstate; the quality of hafnium oxychloride is 0.2 times of the quality of yttrium nitrate hexahydrate);

[0035] (2) 10 mL of concentrated HNO with a concentration of 65% to 68% 3 Add it into the above solution, and under the action of mechanical stirring, the chemical precipitation reaction is uniformly carried out for 20 minutes until a suspension is formed (the volume ratio of nitric acid to deionized water is 1 / 12);

[0036] (3) Add 260 mL of absolute ethanol to the suspension and continue to react for 2 hours. During the entire reaction, the mechanical stirring i...

Embodiment 3

[0041] (1) Dissolve 0.2g of yttrium nitrate hexahydrate and 0.06g of lanthanum nitrate hexahydrate in 120mL of deionized water, stir them with mechanical stirring to fully disperse and dissolve them, and then add 10g of ammonium paratungstate (APT) into it (concentration of ammonium paratungstate in the solution is 0.08g / mL; the quality of yttrium nitrate hexahydrate is 0.02 times of the quality of ammonium paratungstate; the quality of lanthanum nitrate hexahydrate is 0.3 times of the quality of yttrium nitrate hexahydrate);

[0042] (2) Add 30 mL of concentrated HNO with a concentration of 65% to 68% 3 Add it to the above solution, and carry out the chemical precipitation reaction under mechanical stirring for 60 minutes until a suspension is formed (the volume ratio of nitric acid to deionized water is 1 / 4);

[0043] (3) Add 150 mL of absolute ethanol to the suspension to continue the reaction for 5 hours. During the entire reaction process, the mechanical stirring is in wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com