High-purity tert-butyl alcohol online recovery technology for continuously producing potassium tert-butoxide

A technology of potassium tert-butoxide and tert-butanol, applied in the field of preparation of potassium tert-butoxide, which can solve the problems of low production efficiency, high production cost, difficulty in transportation and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

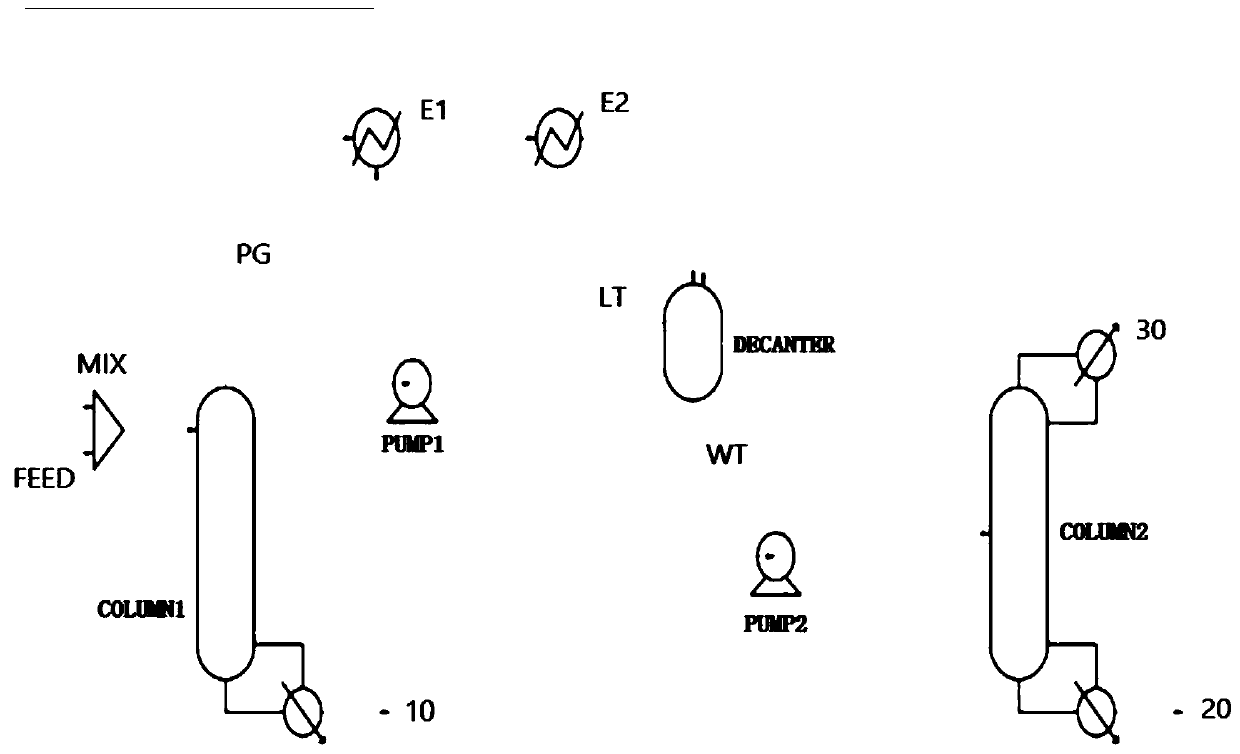

Image

Examples

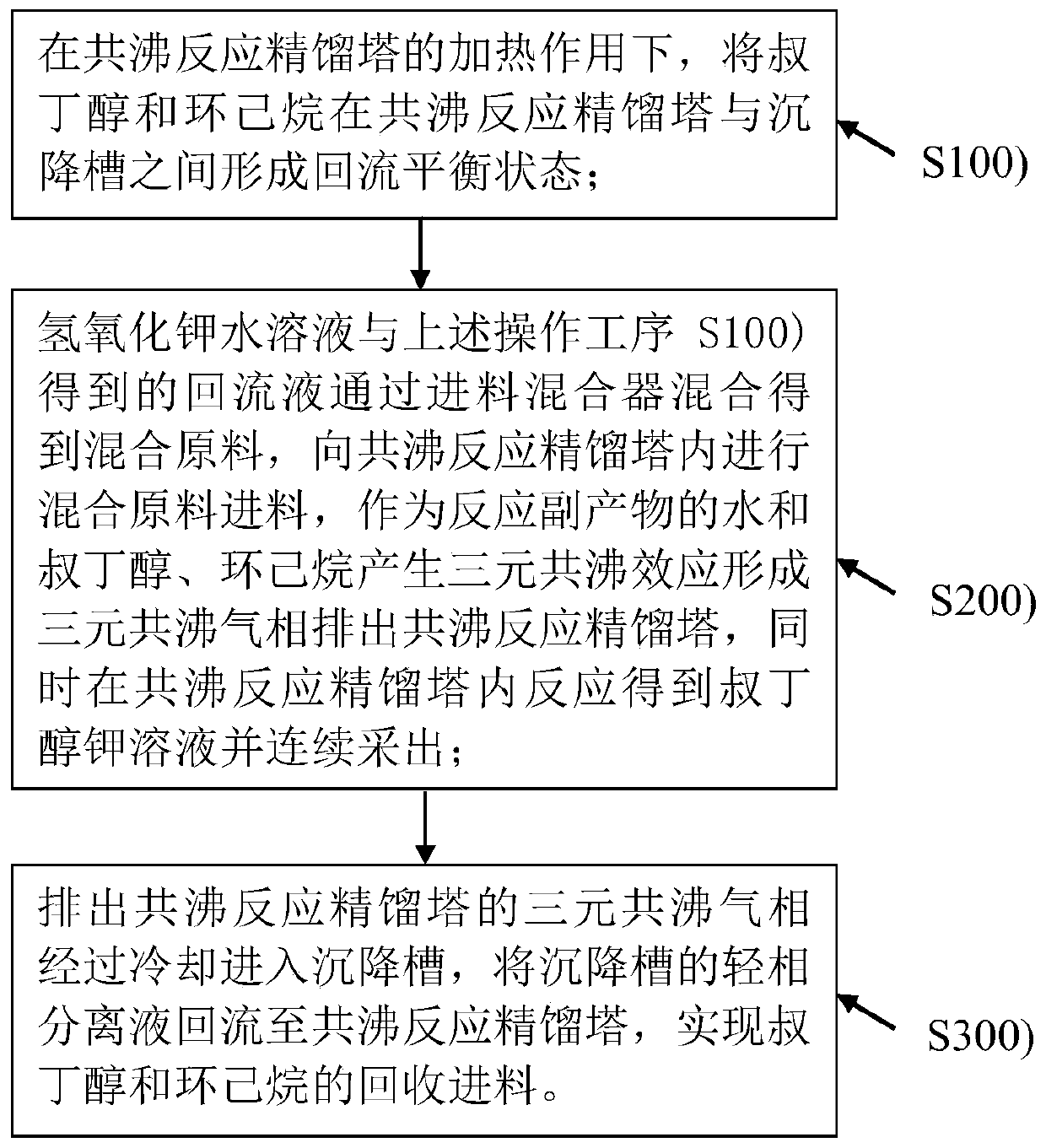

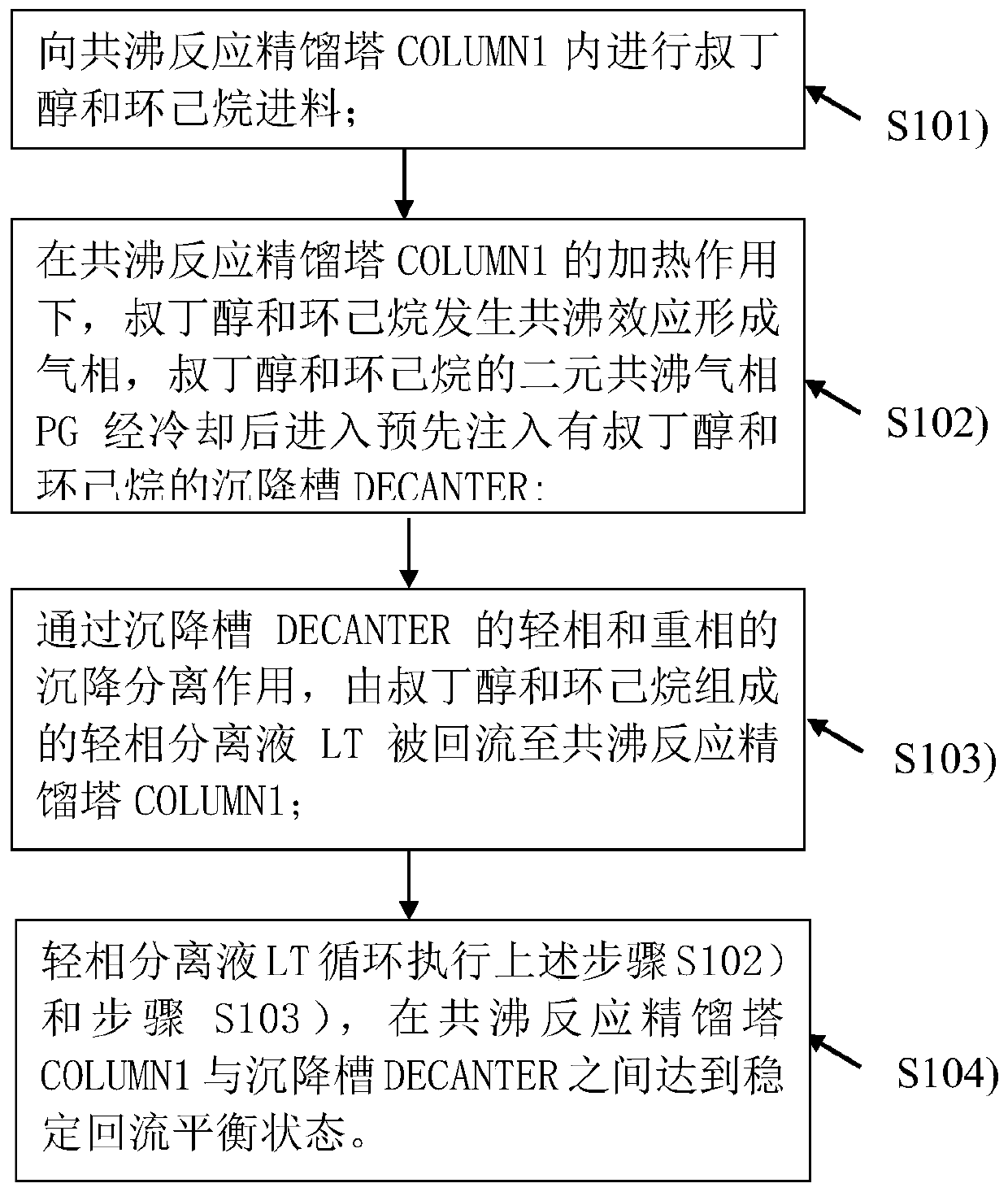

Embodiment 1

[0102] Embodiment 1: In the settling tank DECANTER, pre-inject cyclohexane 1100Kg as base material, tert-butanol 300Kg, then carry out tert-butanol and cyclohexane feed in the azeotropic reaction rectification column COLUMN1, cyclohexane 192Kg, 768Kg of tert-butanol, under the heating action of the azeotropic reactive distillation column COLUMN1, heated until the top temperature of the azeotropic reactive distillation column COLUMN1 is controlled at 65°C, and the temperature of the bottom of the tower is controlled at 85°C; tert-butanol and cyclohexane The binary azeotropic gas phase PG enters the settling tank DECANTER after cooling, and through the settling separation of the light phase and heavy phase of the settling tank DECANTER, the light phase separation liquid LT composed of tert-butanol and cyclohexane is refluxed to the azeotropic reaction The rectification tower COLUMN1 circulates for five hours to ensure a stable reflux balance between the azeotropic reaction rectif...

Embodiment 2

[0106] Embodiment 2: In the settling tank DECANTER, pre-inject cyclohexane 1100Kg as base material, tert-butanol 300Kg, then carry out tert-butanol and cyclohexane feed in the azeotropic reaction rectification column COLUMN1, cyclohexane 192Kg, 768Kg of tert-butanol, under the heating action of the azeotropic reactive distillation column COLUMN1, heated until the top temperature of the azeotropic reactive distillation column COLUMN1 is controlled at 65°C, and the temperature of the bottom of the tower is controlled at 85°C; tert-butanol and cyclohexane The binary azeotropic gas phase PG enters the settling tank DECANTER after cooling, and through the settling separation of the light phase and heavy phase of the settling tank DECANTER, the light phase separation liquid LT composed of tert-butanol and cyclohexane is refluxed to the azeotropic reaction The rectification tower COLUMN1 circulates for five hours to ensure a stable reflux balance between the azeotropic reaction rectif...

Embodiment 3

[0110] Embodiment 3: In the settling tank DECANTER, pre-inject cyclohexane 1100Kg as base material, tert-butanol 300Kg, then carry out tert-butanol and cyclohexane feed in the azeotropic reaction rectification column COLUMN1, cyclohexane 192Kg, 768Kg of tert-butanol, under the heating action of the azeotropic reactive distillation column COLUMN1, heated until the top temperature of the azeotropic reactive distillation column COLUMN1 is controlled at 65°C, and the temperature of the bottom of the tower is controlled at 85°C; tert-butanol and cyclohexane The binary azeotropic gas phase PG enters the settling tank DECANTER after cooling, and through the settling separation of the light phase and heavy phase of the settling tank DECANTER, the light phase separation liquid LT composed of tert-butanol and cyclohexane is refluxed to the azeotropic reaction The rectification tower COLUMN1 circulates for five hours to ensure a stable reflux balance between the azeotropic reaction rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com